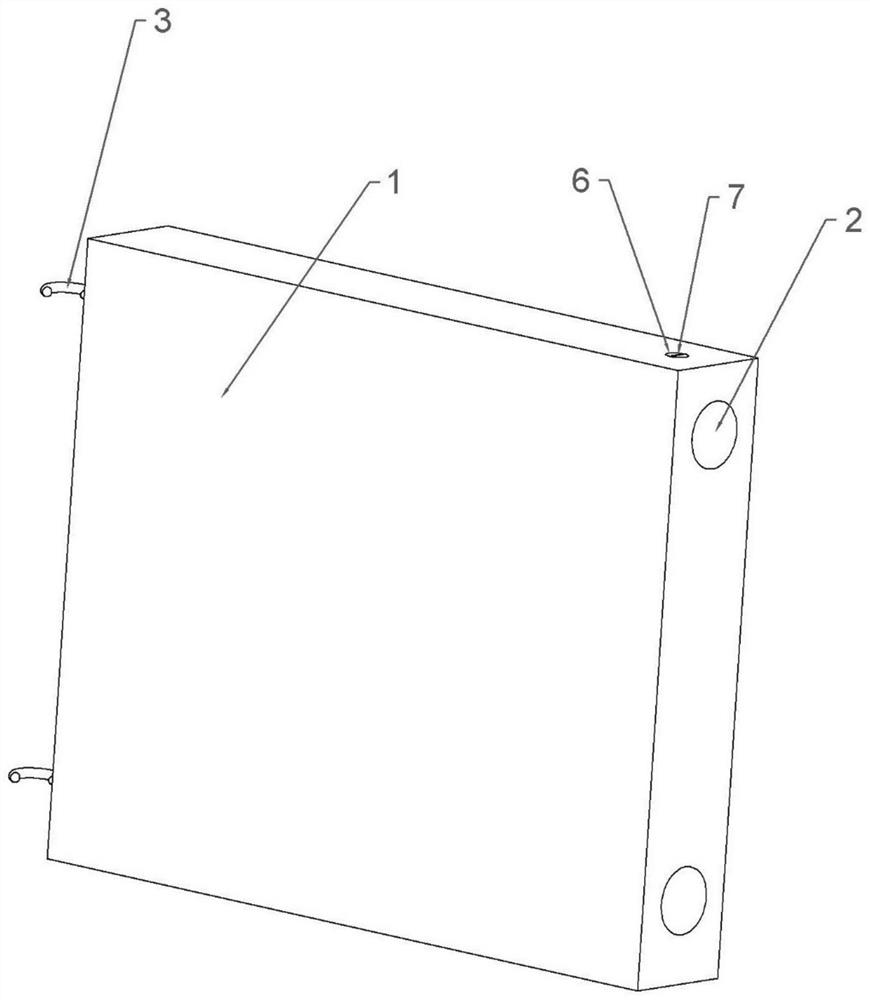

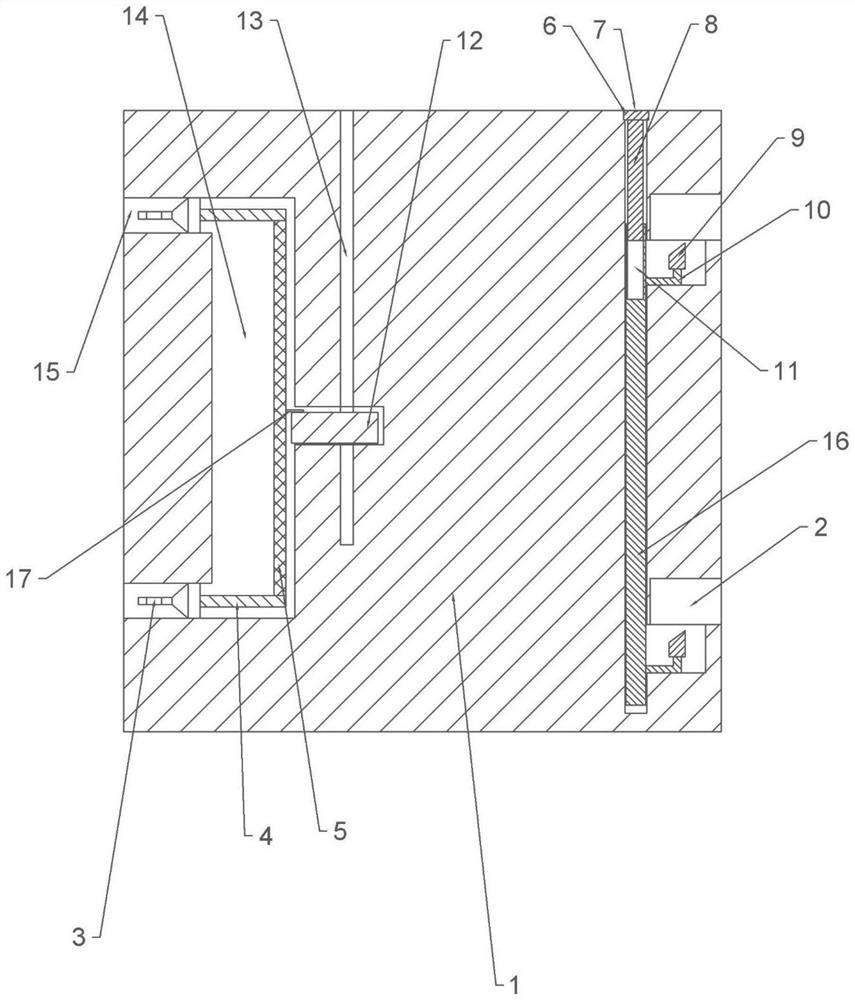

Novel aluminum single plate

An aluminum veneer, a new type of technology, applied in the field of building decoration materials, can solve the problems of difficult disassembly, disassembly or demolition for maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

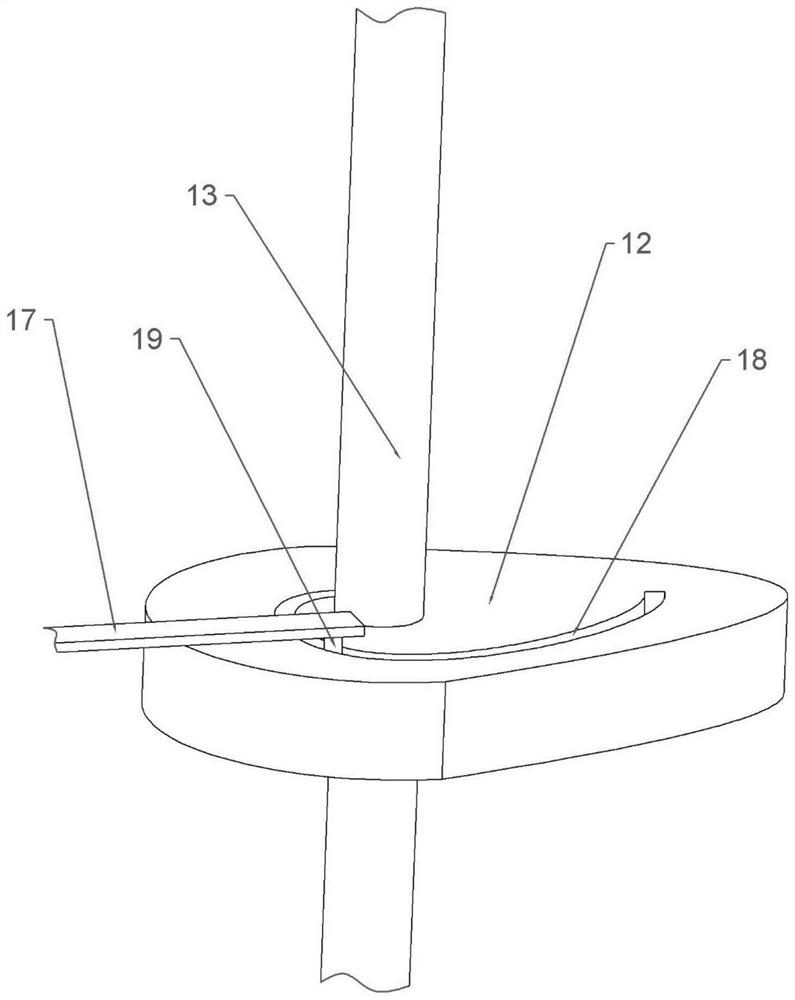

Embodiment 2

[0031] Such as Figure 4 with Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a restricting part that restricts the rotation of the rotating rod 13. The restricting part includes a rotating rod 20, a steel ball 22, a baffle plate 29, a limit plate 26, a slide rod 24 and spring 25. The upper end of the rotating rod 13 is provided with a circular receiving groove, and the inner wall of the receiving groove is evenly provided with a plurality of limiting grooves 21 in the circumferential direction. In this embodiment, the number of limiting grooves 21 is six. The rotating rod 20 is located in the receiving groove and can rotate in the receiving groove. Rotating rod 20 is radially provided with groove 23 , a part of steel ball 22 is located in groove 23 and can slide along groove 23 , and the part of steel ball 22 located in groove 23 is larger than 1 / 2 of the volume of steel ball 22 . A baffle plate 29 is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com