A method of tunnel auxiliary guide pit entering the main hole

A technology of pilot pit and front tunnel, which is applied in the direction of tunnels, earthwork drilling, mining equipment, etc. It can solve the problems of soft rock tunnels such as falling blocks, landslides, increasing construction difficulty and construction period, so as to save roofing and shorten the construction period , The effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0048] The present invention also provides a specific embodiment as follows:

[0049] A high-speed railway tunnel has a total length of 7827.3m and a maximum burial depth of 400m. The surrounding rocks are mainly sandy and carbonaceous shale, with calcite vein interlayers. Running parallel to the fault, the distance is 100-300m. Affected by the bad geological structure, the progress is slow, and the construction period is difficult to meet the requirements.

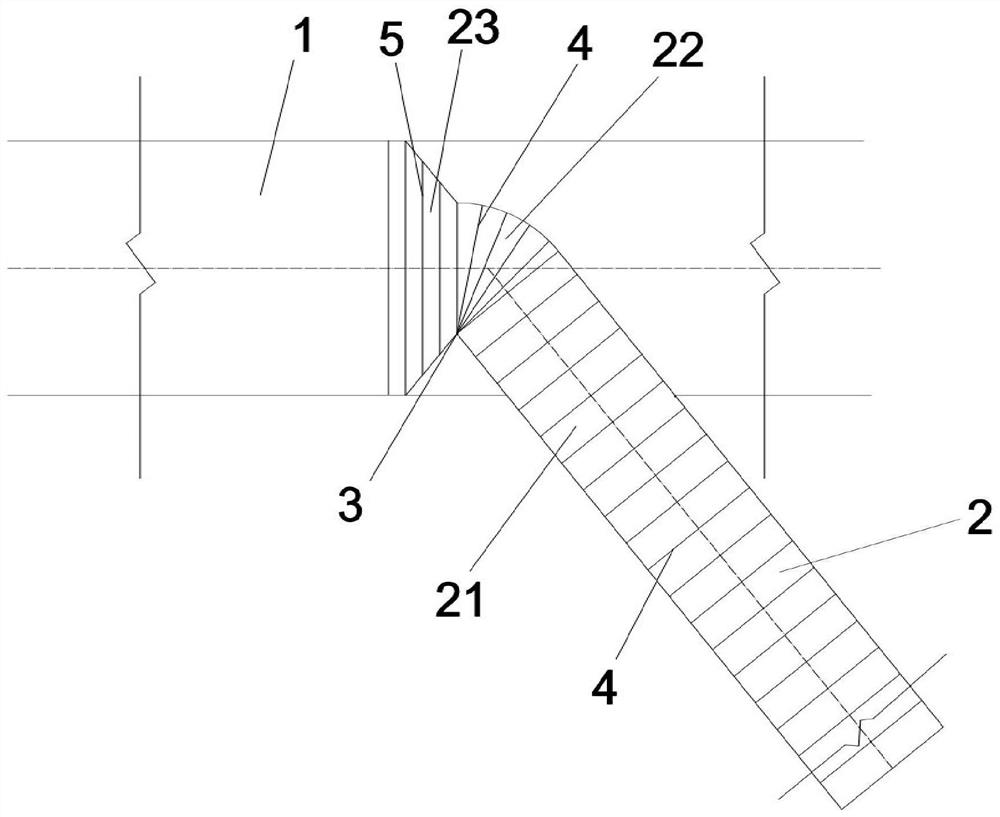

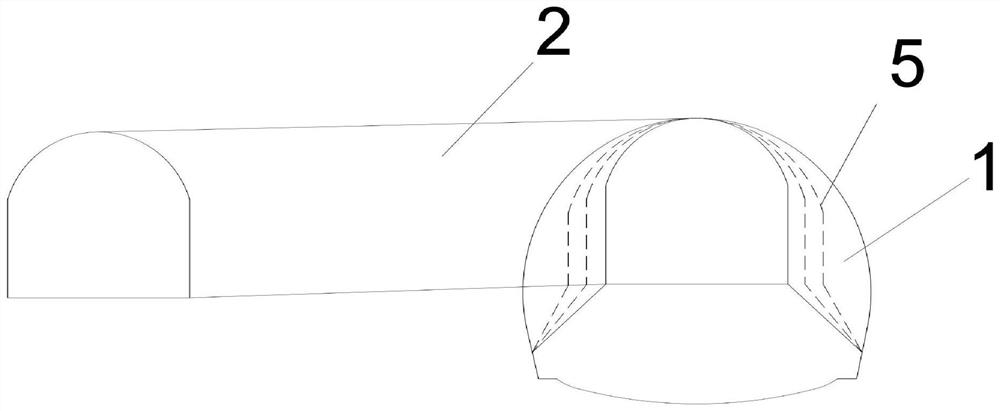

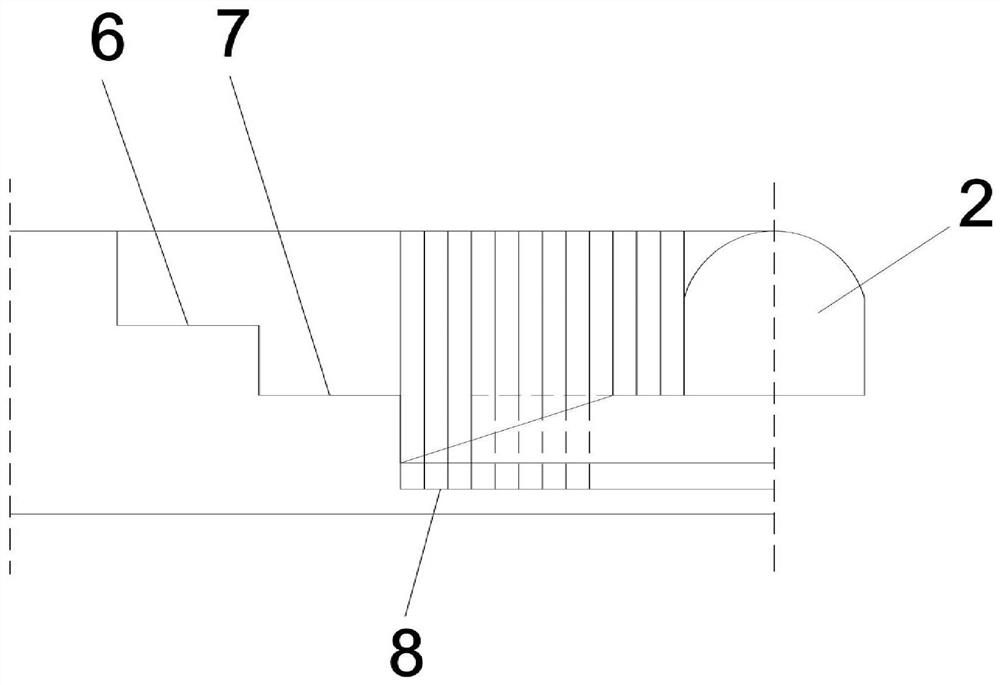

[0050] Before the excavation of the main hole 1, an auxiliary pilot pit 2 is added. Before the auxiliary pilot pit 2 intersects with the main hole 1, it is the excavation stage of the first auxiliary pilot pit 21, which adopts a single-lane anchor shotcrete and a composite lining structure. The clearance is 6.5(W)m×6.2(H)m, the excavation outline is 7.64(W)m×6.96(H)m, and the excavation outline of the main line of the main hole 1 is 14.86(W)m×12.54(H)m.

[0051] ①If figure 1 As shown, the auxiliary guide pit 2 is turned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com