Sound attenuation structure and combustion chamber comprising same

A combustion chamber and noise reduction technology, which is applied to lighting and heating equipment, fluid heaters, etc., can solve the problem of high noise in the combustion chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

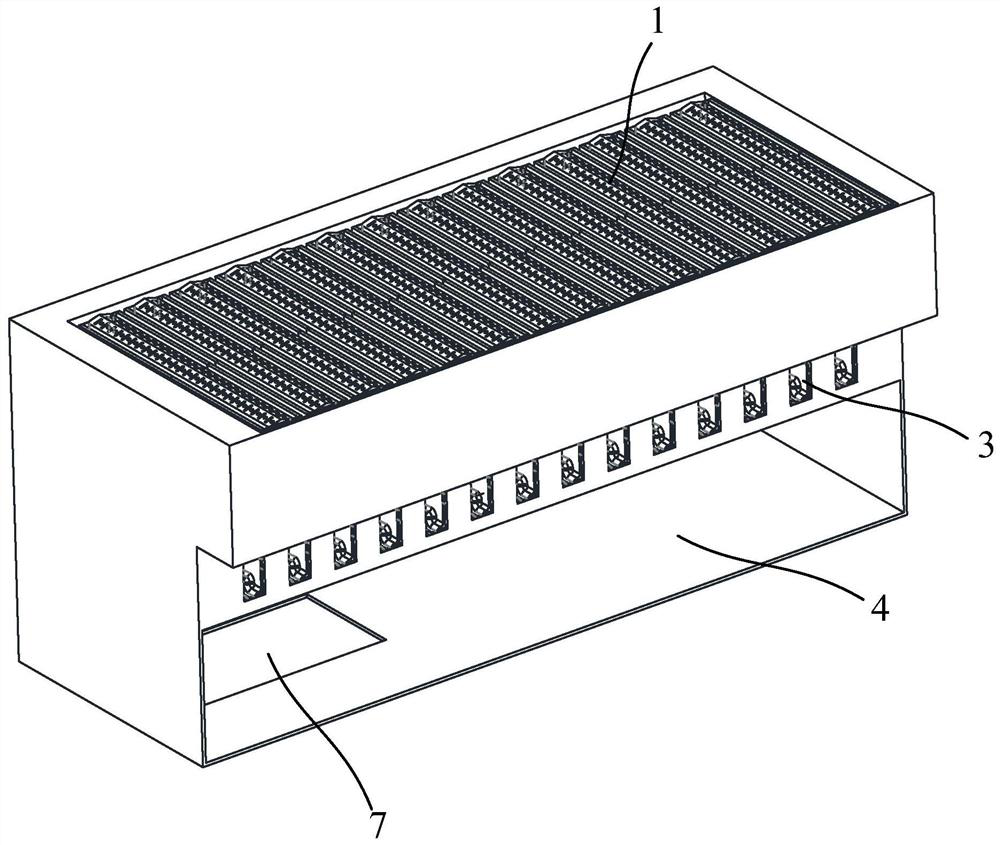

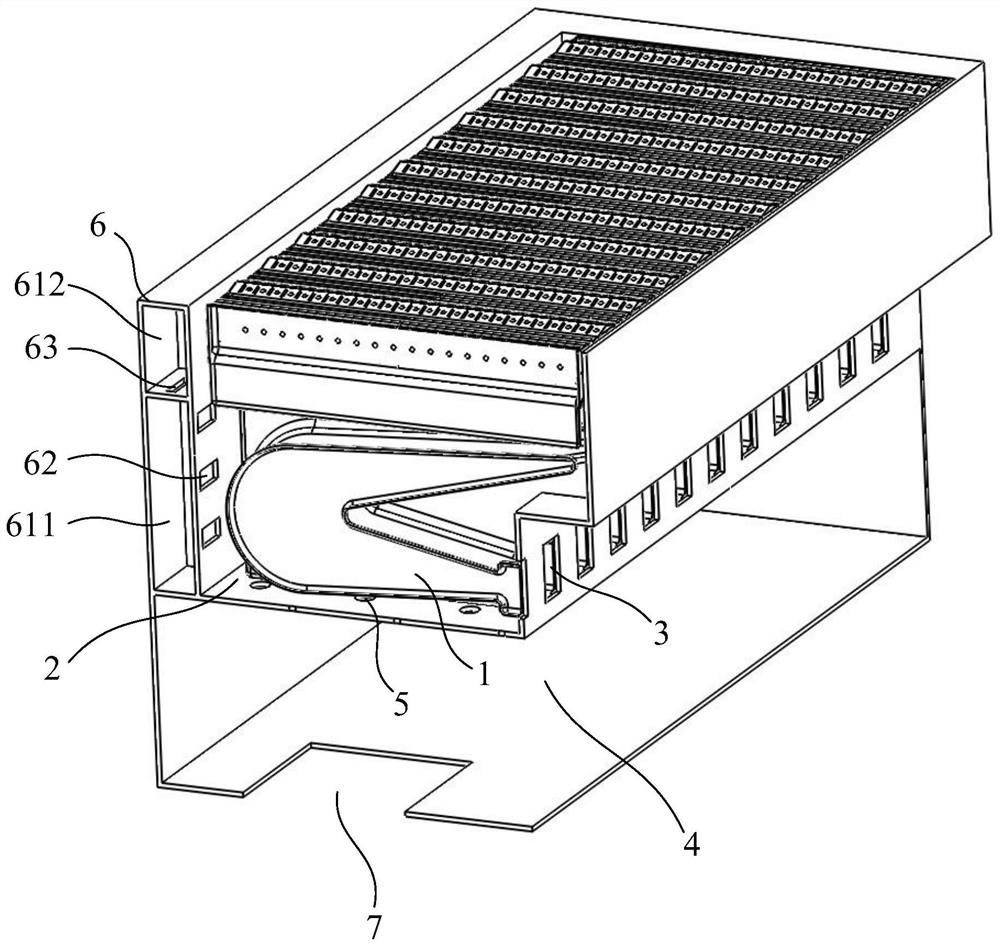

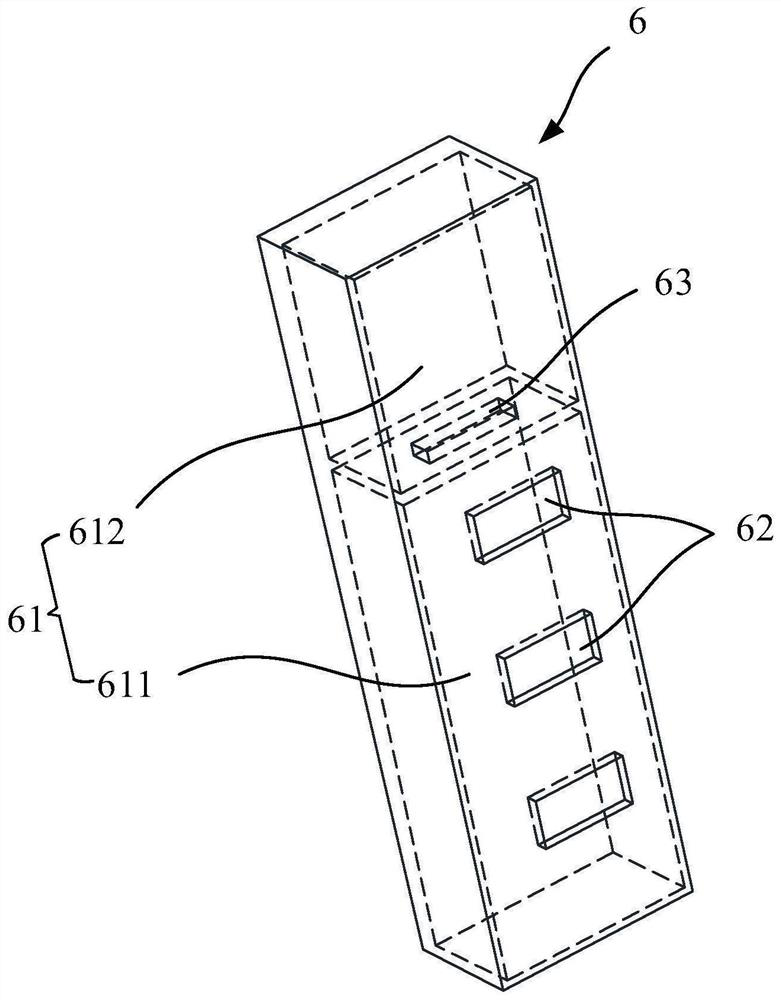

[0052] Such as Figure 1 to Figure 2 As shown, the combustion chamber includes a fire row 1 and a combustion chamber 2 for accommodating the fire row 1. The top of the combustion chamber 2 is an open opening, and the upper end of the fire row 1 with a fire hole protrudes to the top of the combustion chamber 2. . The front of the combustion chamber 2 has a row of gas inlets 3, and the gas inlets 3 communicate with the gas inlets of the fire row 1.

[0053] An air intake chamber 4 is provided below the combustion chamber 2 , a number of air intake holes 5 are provided between the intake chamber 4 and the combustion chamber 2 , and an air intake port 7 is provided below the air intake chamber 4 . The external fan blows air into the air intake chamber 4 through the air inlet 7, and the air in the air intake chamber 4 enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com