Recovery system for waste metal materials after scraped car crushing

A technology of scrapped cars, recycling system, applied in the field of environment, can solve problems such as air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

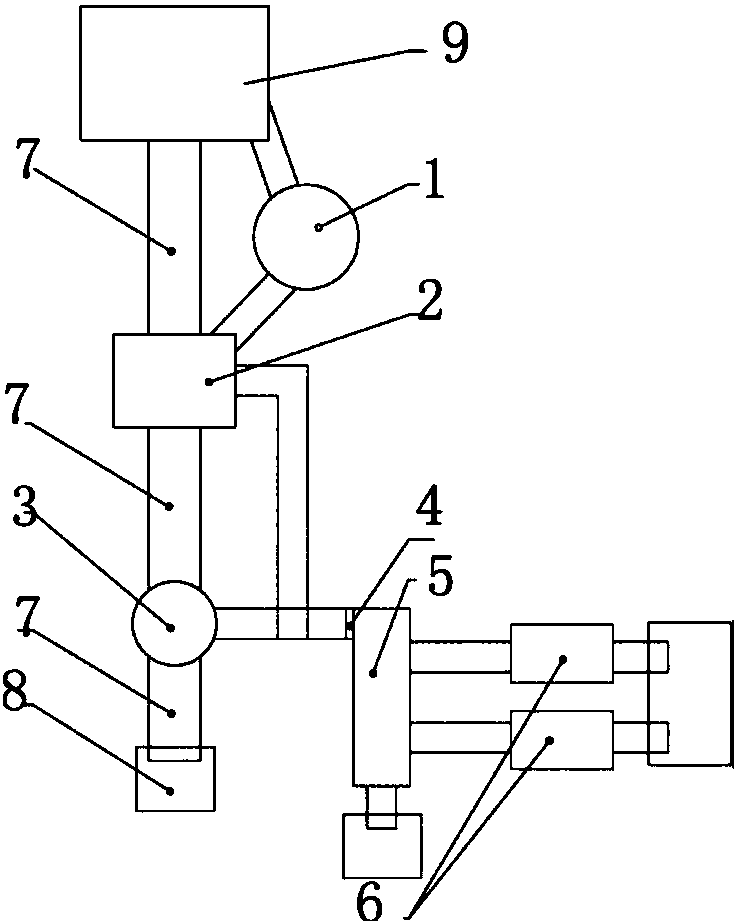

[0012] A recovery system for waste metal materials after scrapped cars are broken, including a dust removal device 1, a drop box air separation device 2, a magnetic separation device 3, a permanent magnet drum device 4, a screening device 5, a non-ferrous metal separation device 6, and a conveyor belt conveyor 7 is connected with the material collection box 8, the drop box winnowing device 2 is connected with the crusher 9 through the conveyor belt conveyor 7, the first dust extraction pipe of the dust removal device 1 is connected with the crusher 9, and the second dust extraction pipe of the dust removal device 1 is connected with On the drop box air separation device 2, the main material outlet of the drop box air separation device 2 is connected with the magnetic separation device 3 through the conveyor belt conveyor 7, and the magnetic material outlet of the magnetic separation device 3 is connected with the material collection box 8 through the conveyor belt conveyor 7 , ...

Embodiment 2

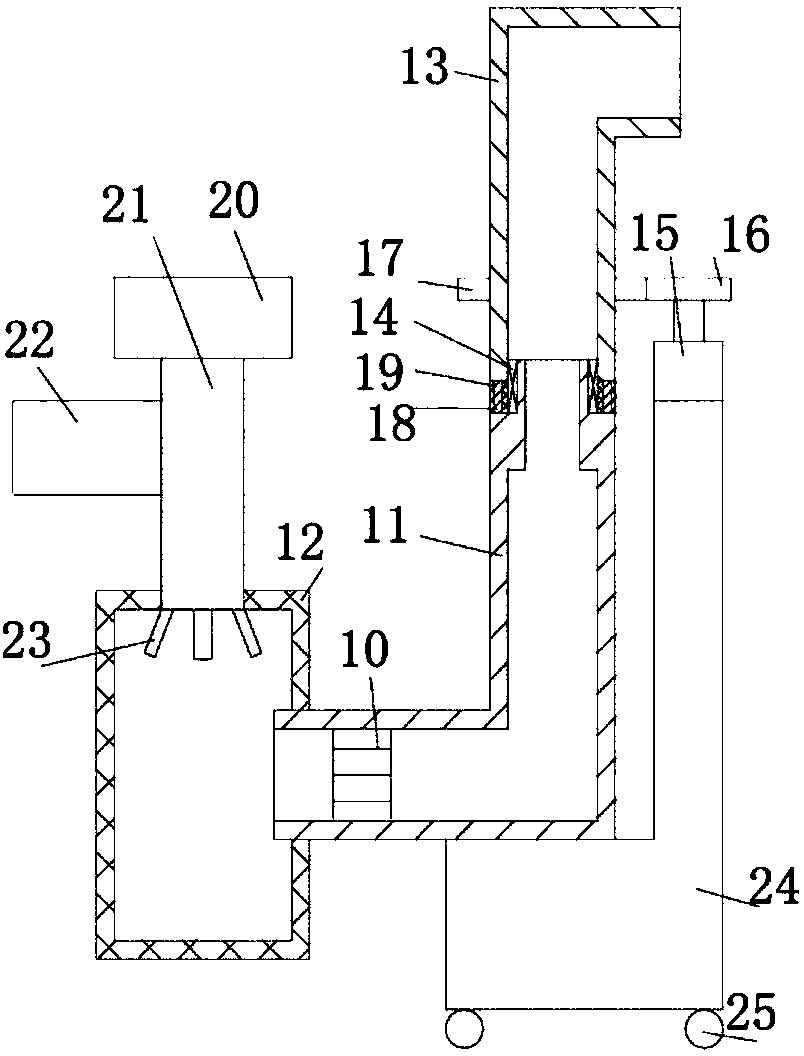

[0014] Such as figure 2 The dust removal device 1 of the present invention includes a fan 10 , a pipeline 11 , a cloth bag 12 , a powder storage 20 , a screw conveyor 21 and a pressure fan 22 . The fan 10 is assembled in the pipeline 11, and the cloth bag 12 is connected with one end of the pipeline 11, and the section of the pipeline 11 is L-shaped. The powder storage 20 is connected to one end of the screw conveyor 12, the other end of the screw conveyor 21 extends into the cloth bag 12, the pressure fan 22 is connected to the screw conveyor 21, and the screw conveyor 21 extends into the cloth bag 12 A plurality of spray heads 23 are provided at the end of the center. It also includes an air intake device and a driving device, the air intake device includes an L-shaped air intake pipe 13 and a bearing 14, the bearing 14 is fixed in the air intake pipe 13, and the end of the pipe 11 is fixedly connected with the inner ring of the bearing 14. The driving device comprises a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com