Hole site measuring device

A technology for hole position measurement and measurement components, which is applied to measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve problems such as errors, low detection efficiency, and difficult positioning, and achieve convenient maintenance, fewer device failures, and convenient measurement data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

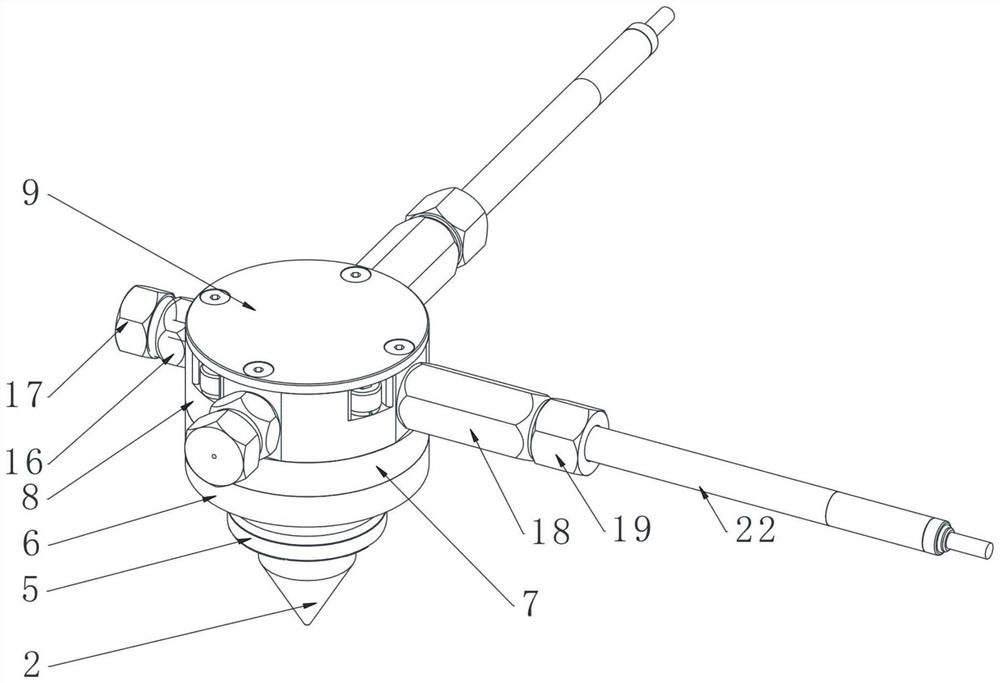

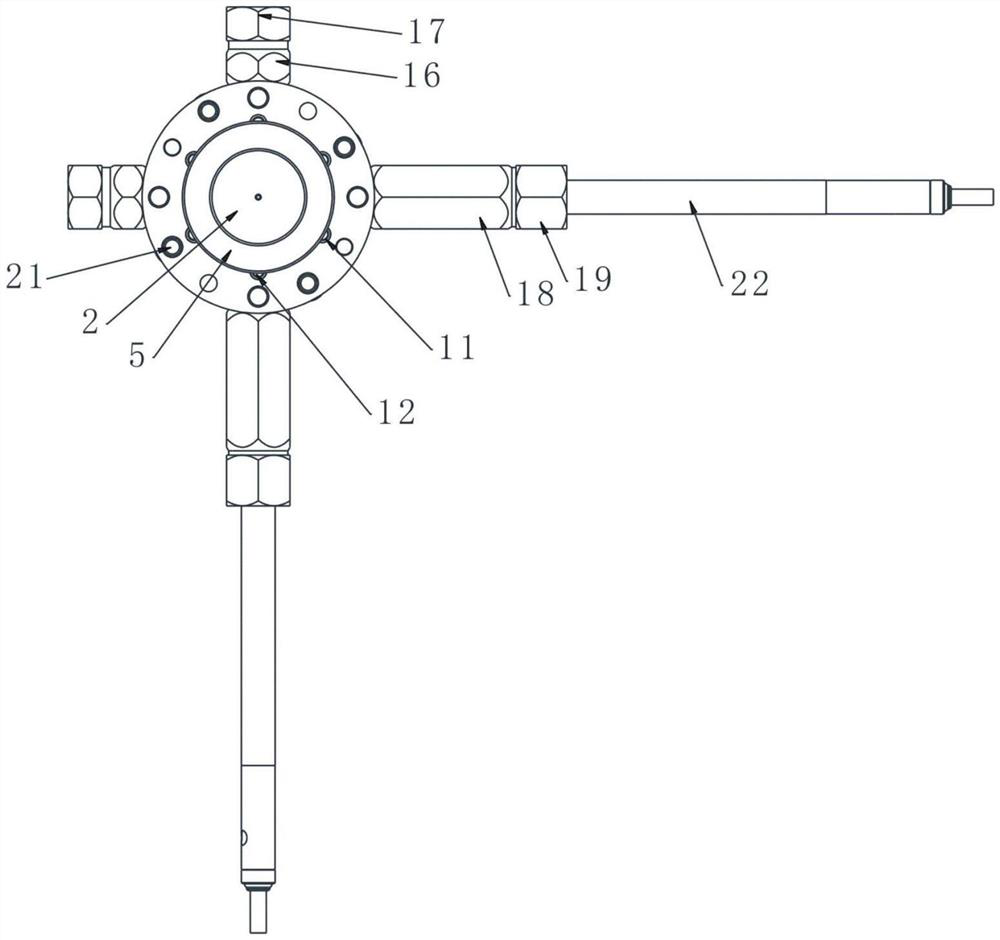

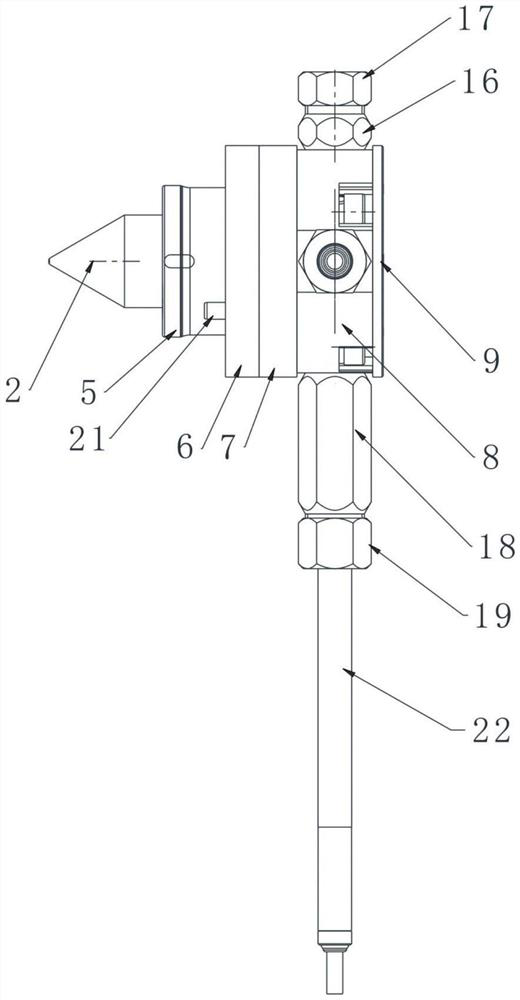

[0037] like figure 1 figure 2 image 3 Figure 4 Figure 5 As shown, a hole position measuring device includes a guide column 1, a measuring head 2, a zero alignment ring 5, a front fixing ring 6, a middle fixing ring 7, a rear fixing ring 8 and a measuring assembly, and the measuring assembly includes a measuring The rod and the dial indicator, the dial indicator probe is in contact with the end of the measuring rod, and the middle part of the guide column 1 is provided with a disc; the lower end of the guide column 1 is equipped with the probe 2, and the upper end surface of the probe 2 is connected to the front fixing ring 6 The lower end surface is in contact, the middle fixing ring 7 is installed on the front fixing ring 6, the disc in the middle of the guide column 1 is located inside the middle fixing ring 7, the rear fixing ring 8 is installed on the middle fixing ring 7, and surrounds the side of the rear fixing ring 8 Set up the measuring assembly, the measuring...

Embodiment 2

[0048] This embodiment is on the basis of embodiment 1, the measurement component is improved to form the second form of the measurement component, the specific design adopted is to use the distance sensor to realize electronization, and the measurement component cancels the dial gauge 22 and related percentages Table installation components, such as guide sleeve 18, lock nut 19, lock sleeve 20, and a distance sensor and signal sending device are added at the rear end of the probe 2. The design of this measurement component can directly obtain the measurement results and send the results to The upper computer can realize faster measurement, and eliminate the unfavorable factors such as errors and mistakes caused by manual reading of data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com