Device and method for detecting clogging degree of submerged nozzle

A detection method and an immersion technology, which are applied in the detection of the clogging degree of the submerged nozzle and the detection device for the clogging degree of the submerged nozzle, which can solve the problems of inability to detect the clogging degree of the nozzle, lagging detection data, and low detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

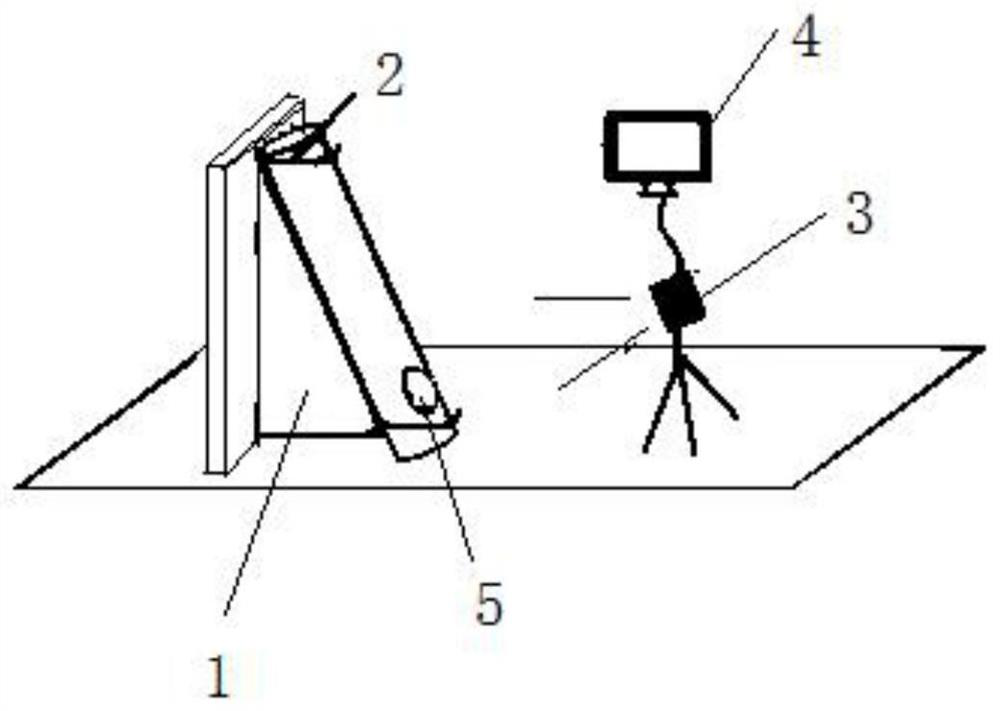

[0034] figure 1 It is a schematic structural diagram of a detection device for the clogging degree of a submerged nozzle in an embodiment of the present invention, as figure 1 As shown, a detection device for the clogging degree of an immersion nozzle, the device includes: a support base 1 , a fixing part 2 , an infrared camera 3 , and a picture analyzer 4 .

[0035]The nozzle is placed on the support seat 1; the fixing member 2 is connected to the support seat for fixing the nozzle on the support seat 1, wherein the outlet 5 of the nozzle is located on the support seat 1 above.

[0036] Further, the support seat 1 is a steel structure.

[0037] Further, there are two or more fixing pieces 2 .

[0038] Further, when there are two fixing pieces 2 , the fixing pieces 2 are respectively arranged at the upper end and the lower end of the support base 1 .

[0039] Specifically, the support base 1 is a steel structure used to support the submerged nozzle, and a support surface i...

Embodiment 2

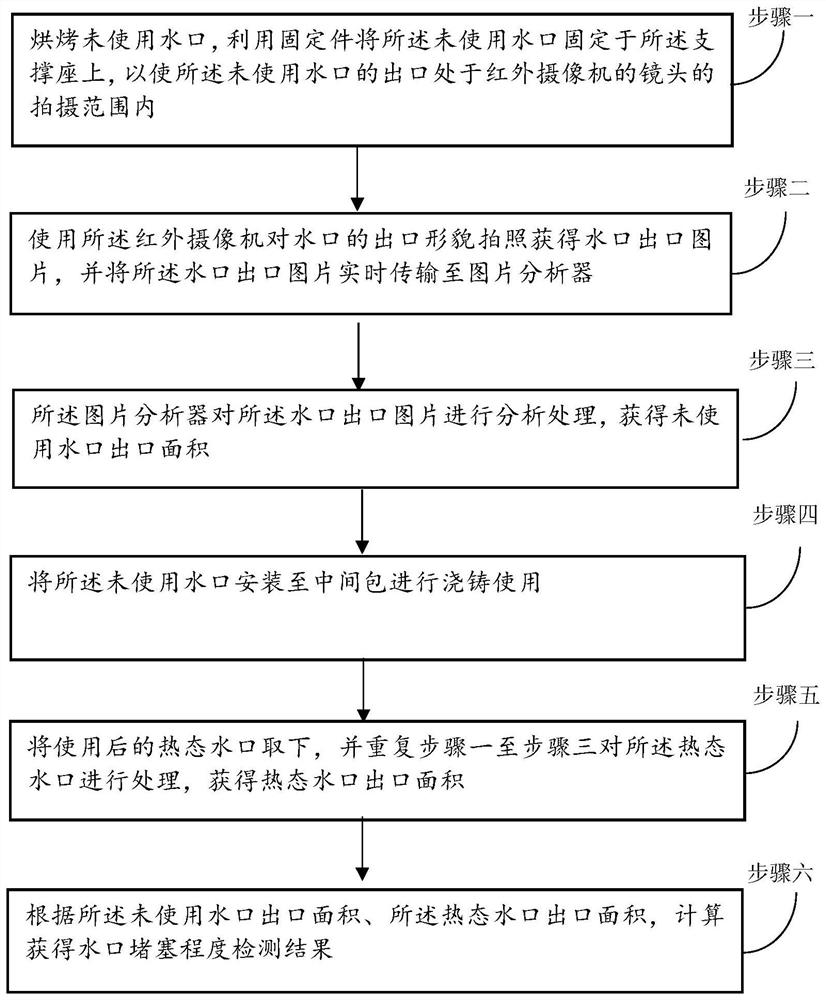

[0044] A method for detecting the clogging degree of the submerged nozzle according to the embodiment of the present invention is applied to the detection device for the clogging degree of the submerged nozzle described in the first embodiment, figure 2 It is a schematic flowchart of a detection method for the clogging degree of a submerged nozzle according to an embodiment of the present invention, please refer to figure 2 , the method includes:

[0045] Step 1: Bake the unused nozzle, and fix the unused nozzle on the support base 1 with the fixing member 2, so that the outlet of the unused nozzle is within the shooting range of the lens of the infrared camera 3 .

[0046] Step 2: Use the infrared camera 3 to take photos of the outlet appearance of the nozzle to obtain a nozzle outlet picture, and transmit the nozzle outlet picture to the image analyzer 4 in real time.

[0047] Specifically, place the unused nozzle for baking on the support seat 1. Baking the unused nozzle...

Embodiment 3

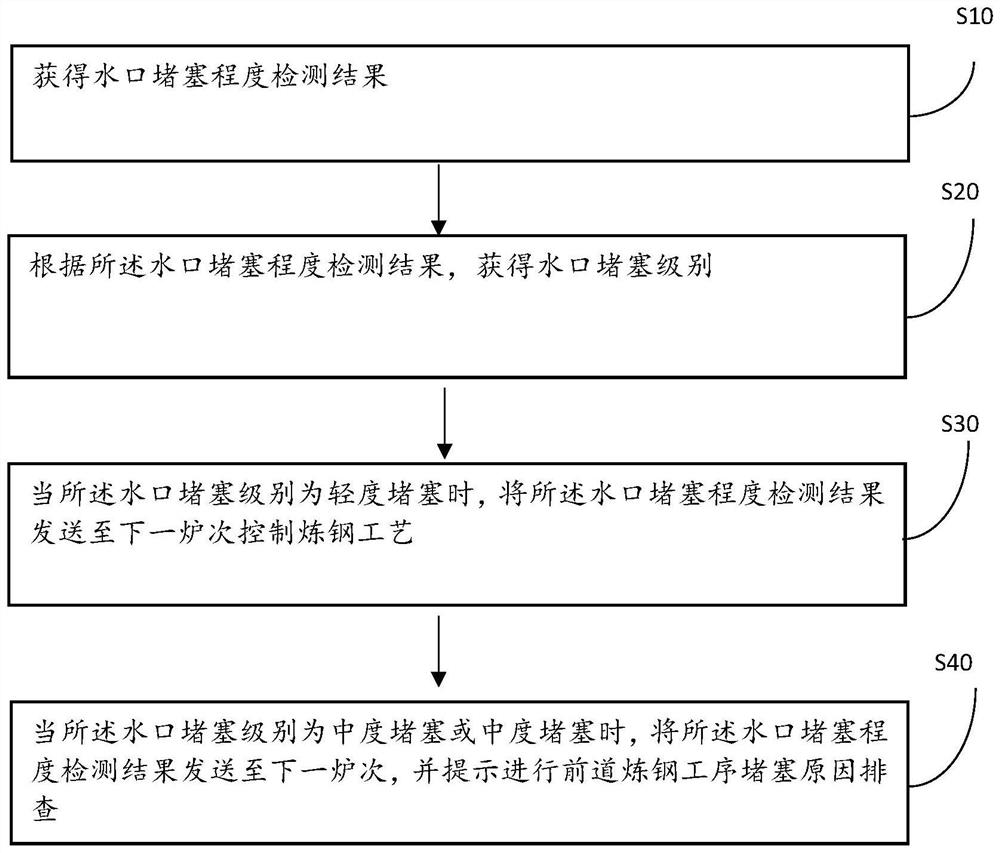

[0061] The embodiment of the present invention provides a steelmaking process control method based on the clogging degree of the submerged nozzle, which is applied to the detection device for the clogging degree of the submerged nozzle described in the first embodiment and the clogging of the submerged nozzle described in the second embodiment In the detection method of the degree, the steelmaking process control method based on the clogging degree of the submerged nozzle includes:

[0062] Step S10: Obtain the detection result of the nozzle clogging degree;

[0063] Step S20: Obtain the nozzle blockage level according to the detection result of the nozzle blockage degree;

[0064] Specifically, utilize the method described in embodiment two to carry out real-time calculation to the area of nozzle outlet by infrared camera 3 and image analyzer 4, utilize formula CI=1-A according to the outlet area before use and the outlet area after use / A0 is used as an index to evaluate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com