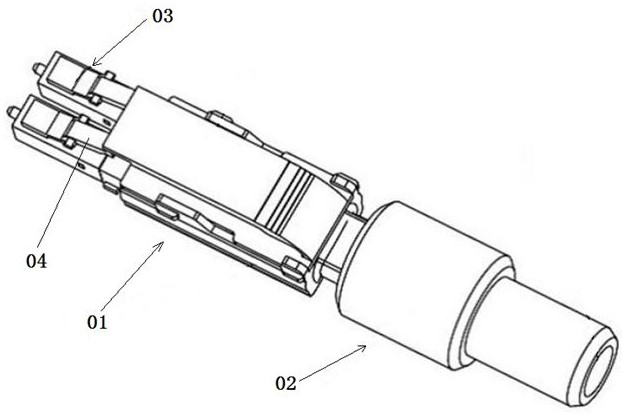

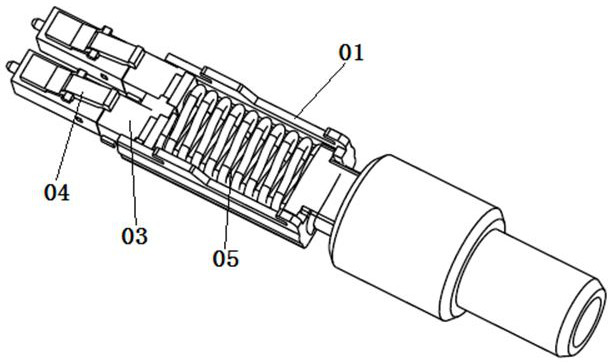

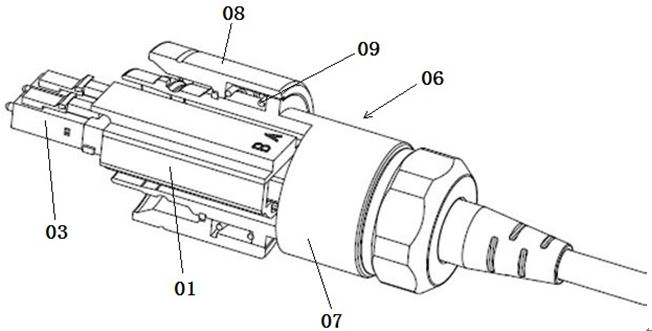

Connector

A technology for connectors and components, applied in instruments, optics, light guides, etc., can solve problems such as cumbersome operations, and achieve the effects of simplified operation steps, high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0060] Embodiment 2 of the connector in the present invention: the difference from the above-mentioned embodiments is that in this embodiment, the unlocking part is linked with the locking cap. One end of the lock cap is drivingly connected with the locking cap through the avoidance structure. The specific structure is as follows: an elongated avoidance hole extending along the insertion direction is arranged on the cylindrical shell, and an installation hole opposite to the elongated avoidance hole is arranged on the locking cap. After the locking cap is sleeved on the cylindrical casing, a plug is inserted into the mounting hole, and the plug can be relatively fixed with the locking cap. When the bolt is fixed with the locking cap, the inner part protrudes into the cylindrical shell through the elongated avoidance hole, and can be inserted into the elongated hole at the rear end of the rear lever arm, and the hole wall of the elongated hole is connected. Block and cooperate...

Embodiment 3

[0061] Embodiment 3 of the connector in the present invention: In this embodiment, the way in which the unlocking member drives the locking shrapnel to act is different from the above-mentioned embodiment, that is, the unlocking member can pull the locking shrapnel on the plug unit backwards, so that the original is tilted up. The locking shrapnel is pulled and then turned down, which can be unlocked with the adapter connector. Specifically, the two elongated body force arms connected to the rotating shaft in Example 1 can be directly replaced with two sections of pull rope, each section of the pull rope can withstand a certain tension. One end of the pull rope in the front section is connected to the locking shrapnel, and the other end is fixedly connected to the outer peripheral surface of the rotating shaft. The connection positions of the rope and the rear section of the rope and the rotating shaft are opposite to the radial direction of the rotating shaft, that is, the tw...

Embodiment 5

[0063] Embodiment 5 of the connector in the present invention: the difference from the above-mentioned embodiments is that the unlocking part in this embodiment includes a rotating shaft, a front lever arm and a rear lever arm connected to the rotating shaft, and the front lever arm can be directly placed on the The locking shrapnel can also be suspended above the locking shrapnel, and the linkage between the rear force arm and the shell assembly is realized by means of hinges. Specifically, a radially extending hinge is arranged inside the cylindrical shell. The hinge arm is provided with a hinge hole, and the rear lever arm is provided with a long hole, and the hinge hole and the long hole can be opposite during the movement stroke of the rear lever arm. A hinge shaft is pierced through the hinge hole and the long hole, and the hinge shaft can also swim in the long hole of the rear moment arm while realizing the hinged connection between the rear lever arm and the hinge arm. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com