Trimming-first and flanging-second mold with pressing function for complex curved surface of lightweight material

A technology of complex curved surface and flanging dies, which is applied in the field of cold stamping dies, can solve the problems of increasing automobile manufacturing costs, irregular cuts of plates, and unqualified products, so as to improve product quality, increase work efficiency, and enhance trimming effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

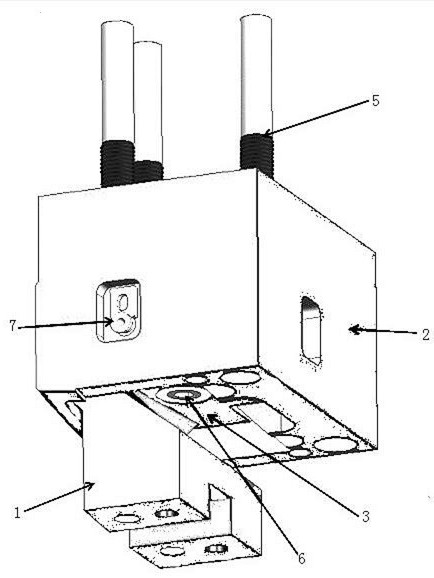

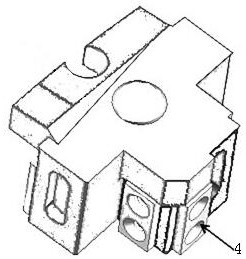

[0014] Such as figure 1 and 2 As shown, the present embodiment provides a light-weight material complex curved surface with a trimming and flanging mold with a pressing function, including a lower mold trimming knife block 1 and an upper mold trimming and flanging knife block 2; The edge trimming knife block 1 is installed in the lower mold body as the cutting edge part of the lower mold; the edge trimming and flanging knife block 2 of the upper mold is installed on the upper mold body to form the edge part of the upper mold; the edge trimming knife block 1 of the lower mold and the upper mold Trimming and flanging knife blocks 2 are set up and down relative to each other; the inner bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com