Manufacturing installation and method for the additive manufacturing of components with material overhang

A manufacturing device and additive manufacturing technology, applied in the field of manufacturing devices and methods for additive manufacturing of parts with material protruding parts, can solve the problems of prolonging the time of manufacturing parts, large material consumption, etc., to improve usability and reduce manufacturing costs , the effect of preventing heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the different figures, identical parts always have the same reference numerals and are therefore usually only described once.

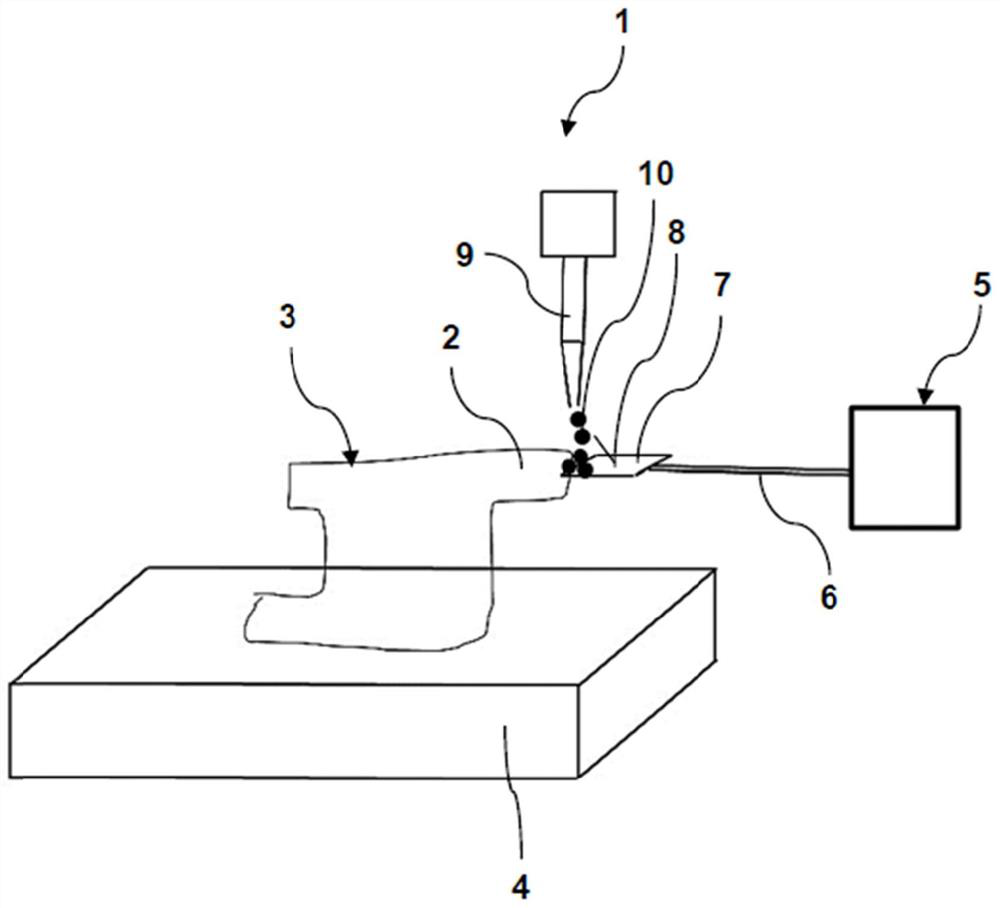

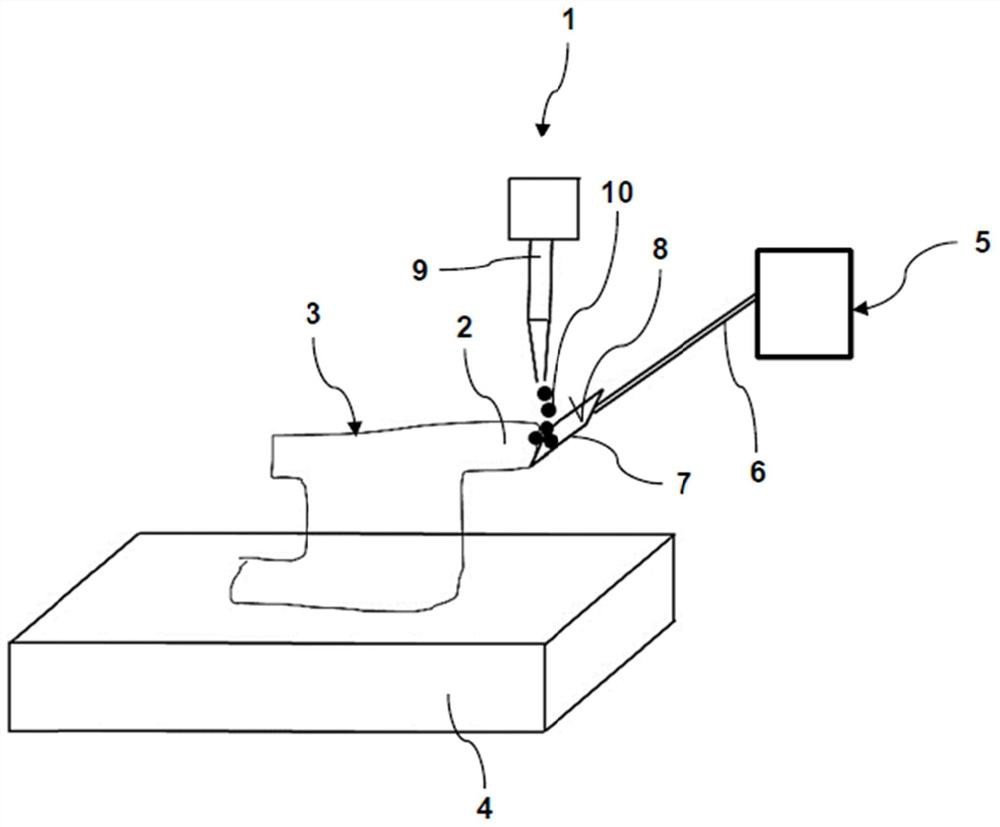

[0034] figure 1 A schematic diagram showing an exemplary embodiment of a manufacturing device 1 according to the invention for the additive manufacturing of components 3 each having at least one material protrusion 2 in a functional state.

[0035] The manufacturing device 1 has a construction platform 4 on which specific components 3 can be at least partially additively produced. The building platform 4 is formed as a planar fabrication workbench.

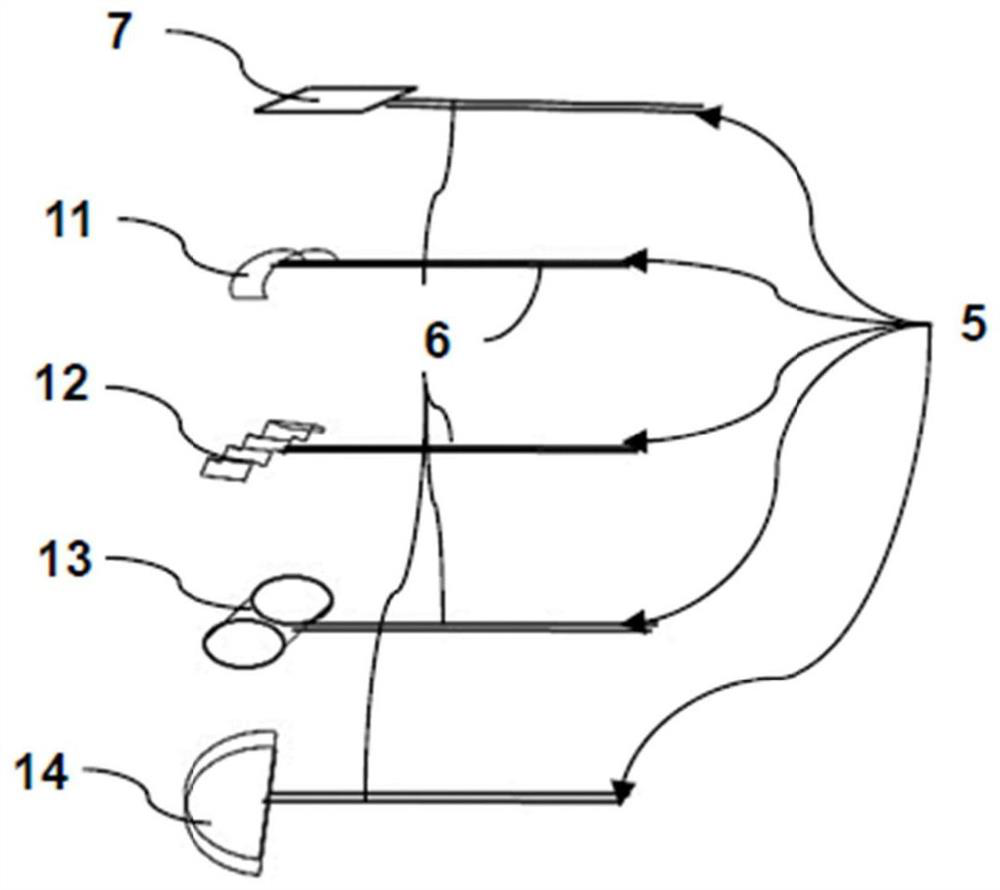

[0036] Furthermore, the production device 1 has a support device 5 whose spatial position can be controlled, for example electrically. Such as figure 1 and 2 As shown, the support device 5 may be referred to as an electrically controllable support device 5 and has a movable support arm 6 which is used for at least At least one support element 7 arranged on the support arm 6 is temporarily h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com