Container spreader closed shutter

A container spreader, closed technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of large crane hook travel, unable to meet low clearance lifting operations, etc., to achieve good lubrication effect, reversing stroke The effect of shortening and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

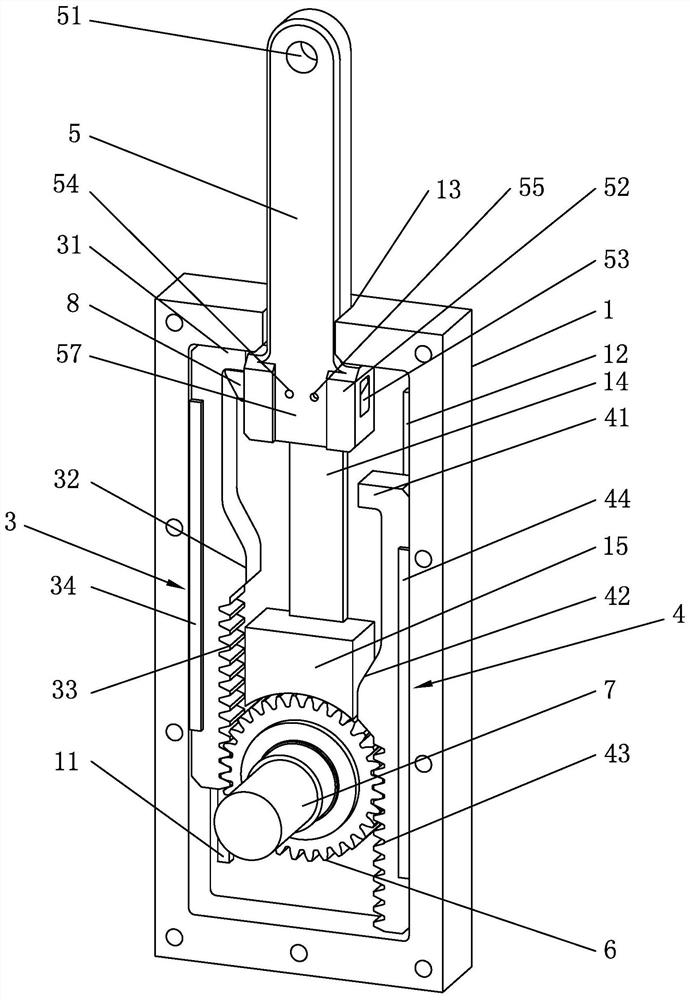

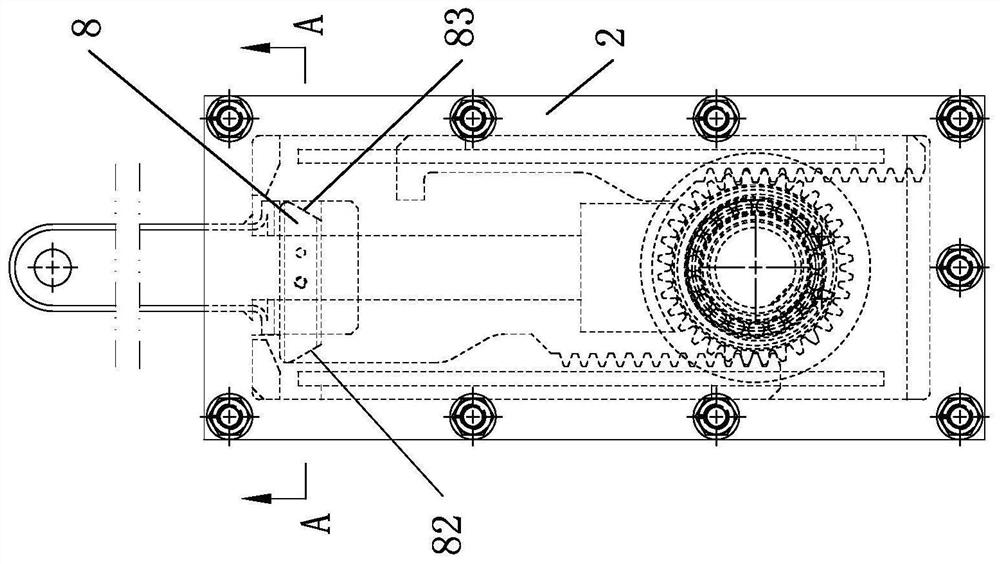

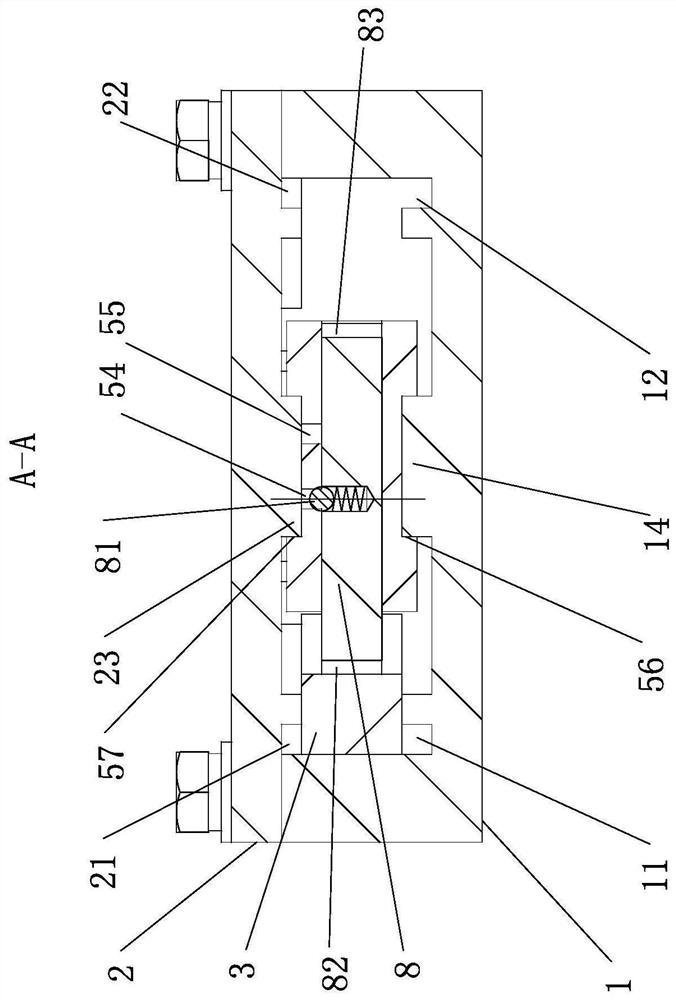

[0014] Such as figure 1 with figure 2 As shown, the container spreader closed switch of the present invention includes a vertically placed box body 1 and a box cover 2 connected to the open end of the front side of the box body 1 by bolts. , also includes a pull rod 5 at the center and a gear transmission mechanism located below the pull rod 5 . The upper end of pull rod 5 is positioned at the outside of closed box and is connected with crane. Such as Figure 5 with Image 6 As shown, the front and rear ends of the gear shaft 7 of the gear transmission mechanism pass through the case cover 2 and the casing 1 respectively, and are respectively connected with transmission mechanisms 95,96 fixed on the left and right sides of the hanger 94 of the container spreader. The lower end of the shutter is welded on the hanger 94 of the spreader.

[0015] Such as Figure 1 to Figure 4 As shown, the top of the box body 1 has a square hole 13 that cooperates with the pull rod 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com