Oblate variable-cross-section steel pipe arch and manufacturing process thereof

A technology of manufacturing process and variable section, applied in the field of bridge manufacturing, can solve problems such as single shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

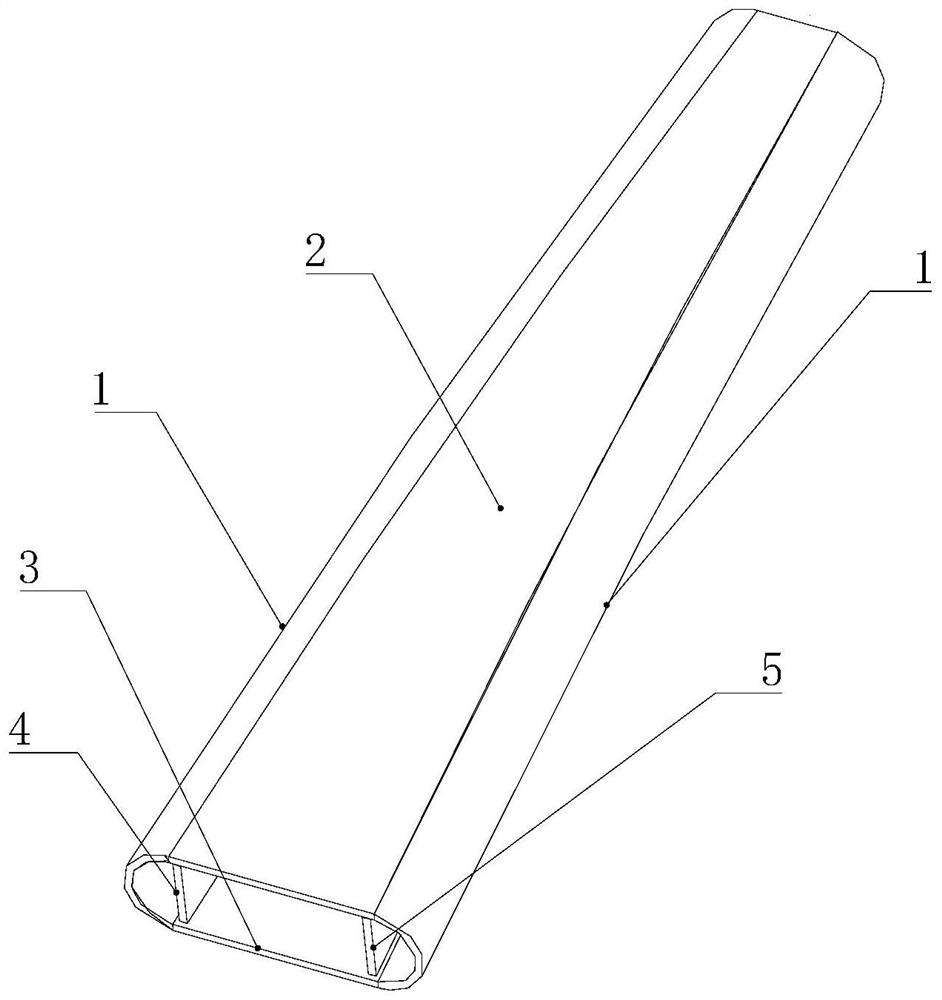

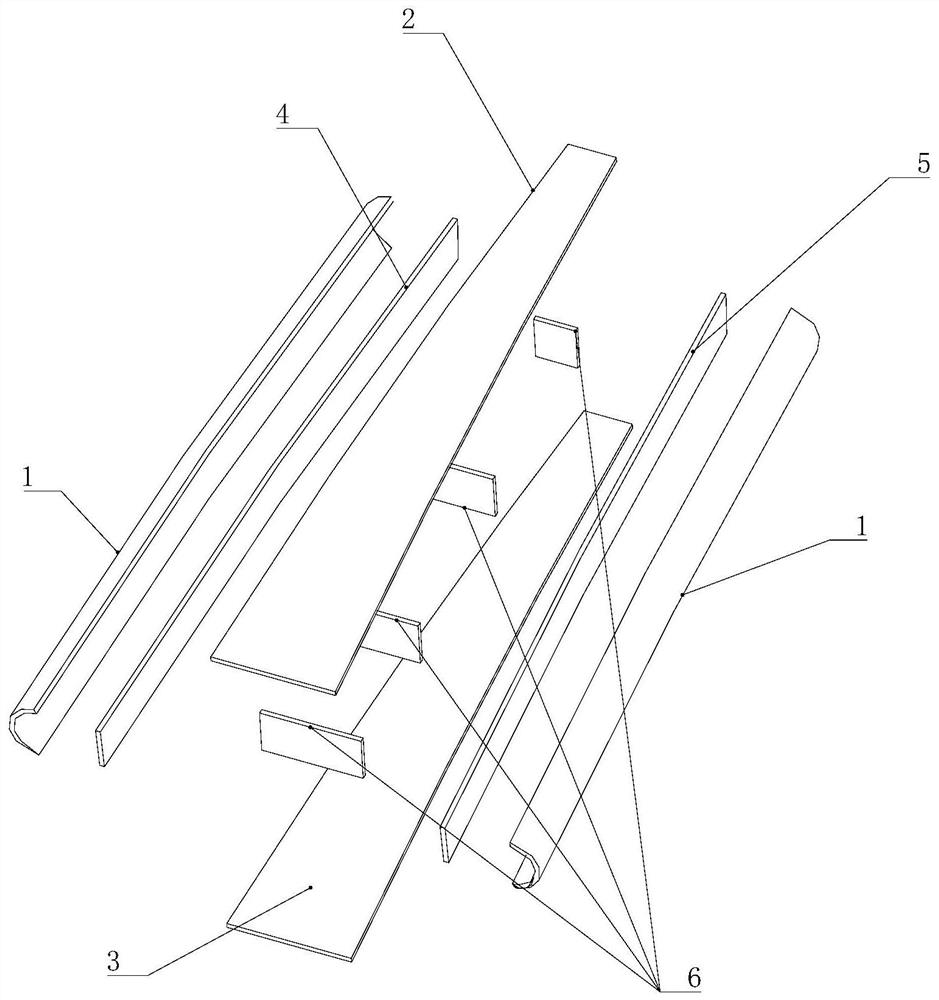

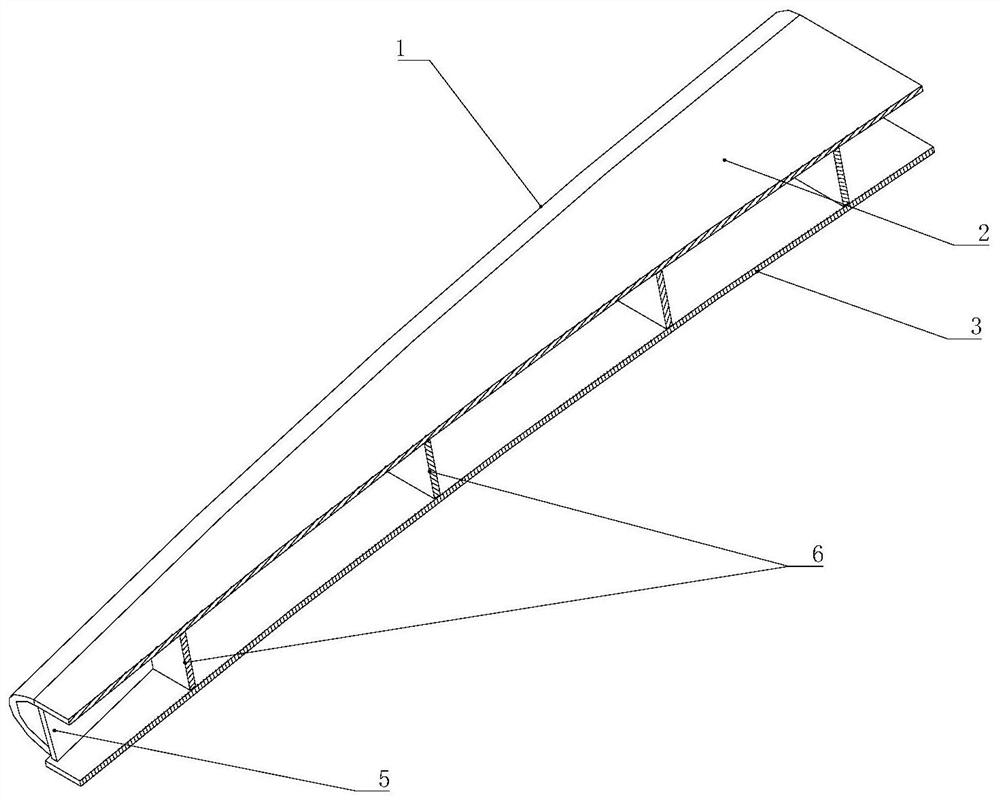

[0015] Such as Figure 1 to Figure 3 The steel pipe arch shown includes a square tube transition piece, which is trumpet-shaped and has a certain radian, and arc-shaped semicircular tubes 1 with a radian are welded on both sides of the square tube transition piece, and a cross-sectional gradient is formed through the above structure. Radian oblate steel pipe arch, such as figure 2 The square tube transition piece shown includes an upper wall plate 2, a lower wall plate 3, a left web plate 4 and a right web plate 5, the upper wall plate 2 and the lower wall plate 3 are isosceles trapezoidal, the left web plate 4 and the right web plate The plate 5 is equal in width and has a certain radian. The edges of the upper wall plate 2, the lower wall plate 3, the left web plate 4 and the right web plate 5 are welded together to form a square tube, wherein the upper wall plate 2 and the lower wall plate 3 are opposite to each other. , the left web 4 and the right web 5 are opposite, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com