Cam rotor pump

A cam rotor pump and cam rotor technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve the problems of reduced energy efficiency of the device, difficulty in ensuring the tightness of the rotor and the pump body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

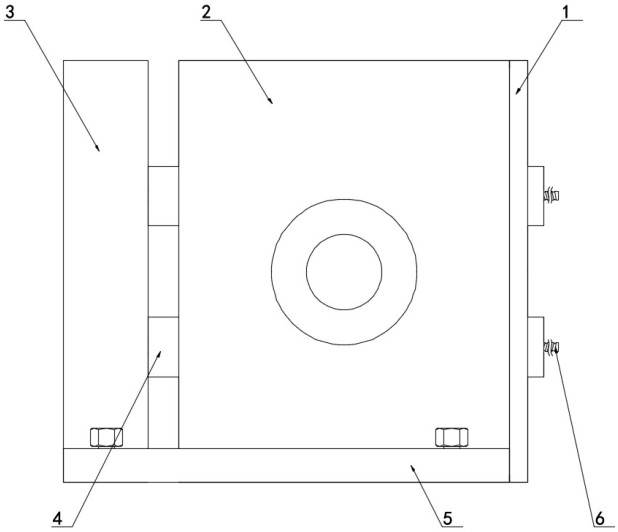

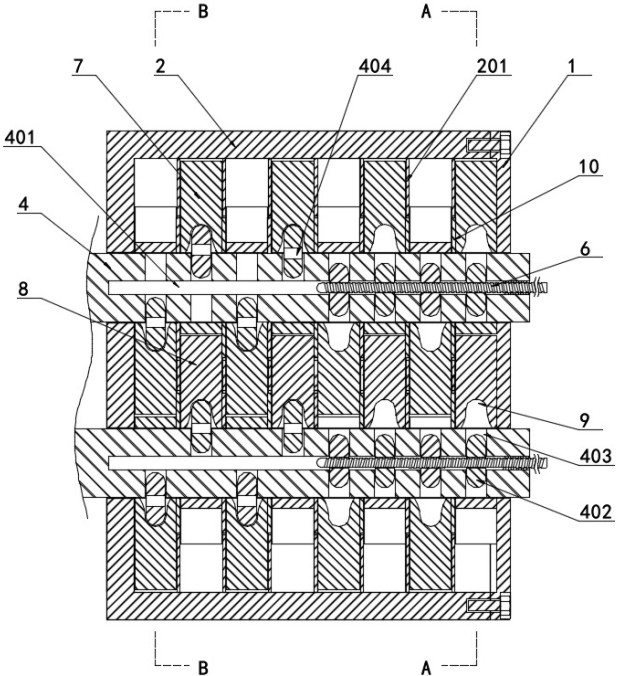

[0024] Embodiment one, with reference to Figure 1-4 , the lobe rotor pump, including a fixed base 5 and a drive mechanism 3 fixedly installed on the fixed base 5 and a pump casing 2, and also includes two transmission shafts 4 fixedly connected to the output end of the drive mechanism 3, and the inner cavity of the pump casing 2 is fixed with at least A spacer 201, at least one rotor mechanism is rotatably connected to the inner cavity of the pump casing 2, and the outer cover 1 is detachably installed at the opening of the pump casing 2, and the two transmission shafts 4 run through the pump casing 2 and are sleeved on the extension end of the outer cover 1. The adjusting screw 6, the rotor mechanism includes a first cam rotor 7 and a second cam rotor 8, the sides of the first cam rotor 7 and the second cam rotor 8 are fixedly connected with an isolation disc 10, and the isolation disc 10 and the isolation disc 201 have a through hole The first cam rotor 7 and the second cam...

Embodiment 2

[0025] Embodiment two, refer to Figure 1-4 , the first cam rotor 7 and the second cam rotor 8 are rotationally connected with the two transmission shafts 4 respectively, and the center of the transmission shaft 4 is provided with a shaft hole 401, and the shaft hole 401 is screwed and connected with the adjusting screw 6, and the transmission shaft 4 is radially At least one through hole 403 is opened, at least one through hole 403 is vertically connected with the shaft hole 401, at least one through hole 403 runs through the outer wall of the transmission shaft 4, at least one through hole 403 is slidingly connected with a clamping rod 402, the first The centers of the cam rotor 7 and the second cam rotor 8 are provided with a card slot 9, the card slot 9 is engaged with the card rod 402, and at least one card rod 402 is provided with a center hole 404, and the center hole 404 is in clearance fit with the adjusting screw rod 6 After the adjusting screw 6 is inserted into the...

Embodiment 3

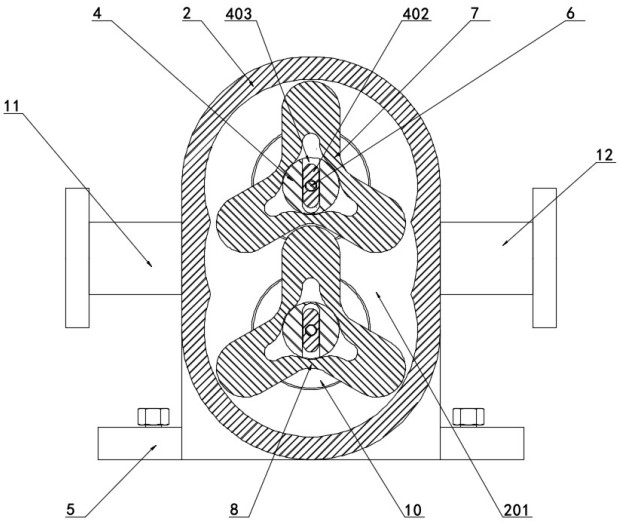

[0026] Embodiment three, refer to image 3 A water inlet pipe 11 and a water outlet pipe 12 are fixedly installed on both sides of the pump casing 2, so as to facilitate the delivery of liquid to the pump casing 2.

[0027] Working principle: firstly, through the isolation between multiple first cam rotors 7 and multiple second cam rotors 8 by multiple spacers 201, and the rotational connection between the spacer disc 10 and the through hole at the center of the spacer disc 201, the isolation The disk 10 separates multiple rotor mechanisms, so that the multiple rotor mechanisms work independently of each other, avoiding the failure of a single rotor mechanism causing the failure of the entire device; secondly, through the sliding connection between the clamping rod 402 and the through hole 403 , and the screw-in connection between the adjusting screw 6 and the shaft hole 401, so that the adjusting screw 6 is screwed into the shaft hole 401 and inserted into the center hole 404...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com