Hydraulic plug-in mounting integration block structure

A hydraulic integrated and plug-in technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of affecting work efficiency, time-consuming and labor-consuming and inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

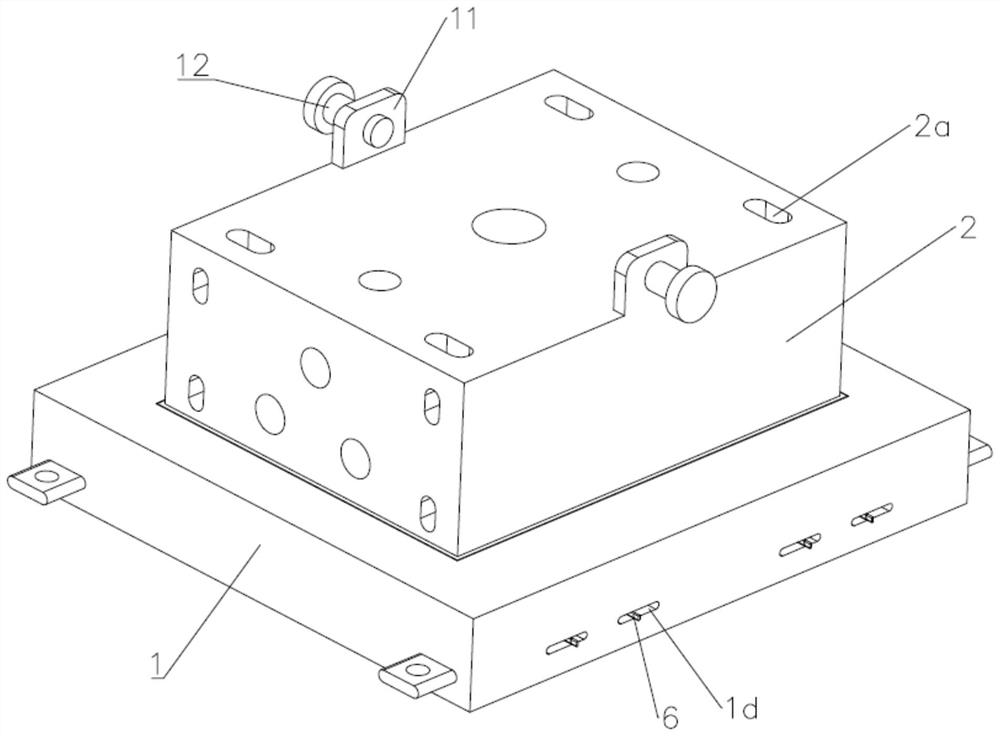

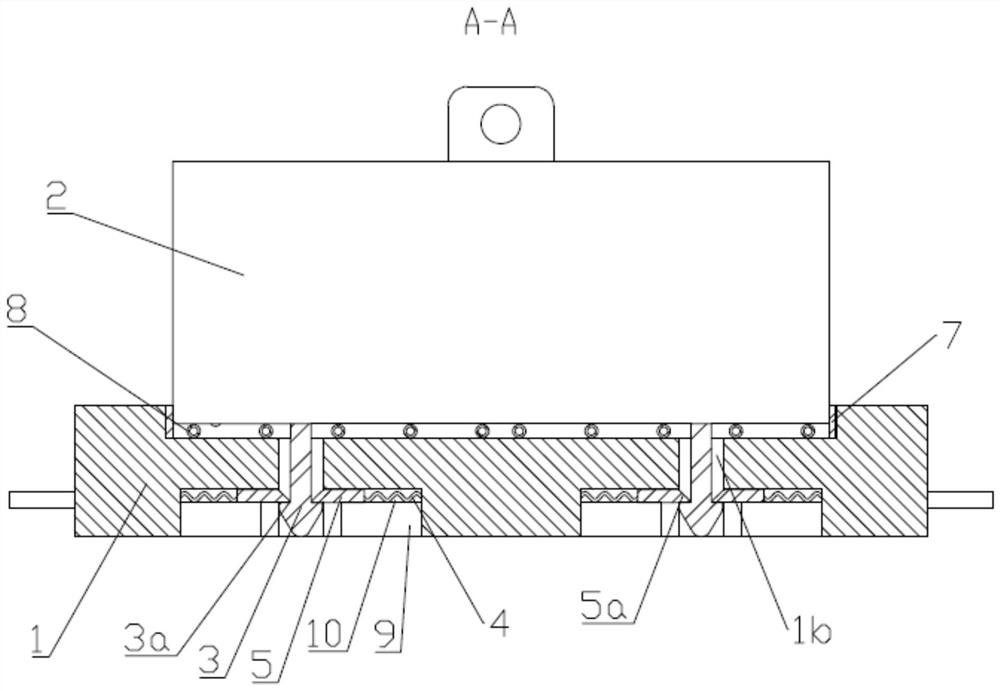

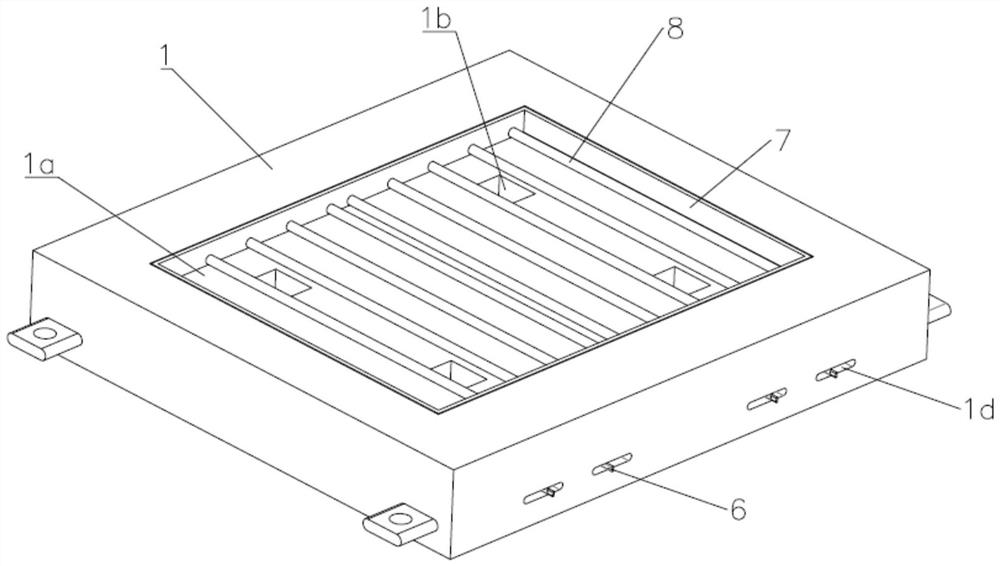

[0027] see Figure 1-Figure 6 As shown, the present invention provides a hydraulic plug-in integrated block structure, including a base 1 for installation on a hydraulic load-bearing platform, and a hydraulic integrated block 2 detachably installed on the base 1, and the top of the hydraulic integrated block 2 There are multiple installation holes 2a for the integrated installation of different hydraulic valves. The hydraulic manifold 2 is also provided with multiple hydraulic medium flow channels. The bottom of the hydraulic manifold 2 is provided with an insert 3, and the top of the base 1 is provided with The lower end of the hydraulic integrated block 2 fits the card slot 1a, and the bottom of the card slot 1a is provided with a jack 1b for the insertion block 3 to move up and down, and the bottom of the base 1 is provided with a limiting groove 1c communicating with the jack 1b. The slot 1c is installed with an elastic member 4 and a stop block 5 fixed at one end of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com