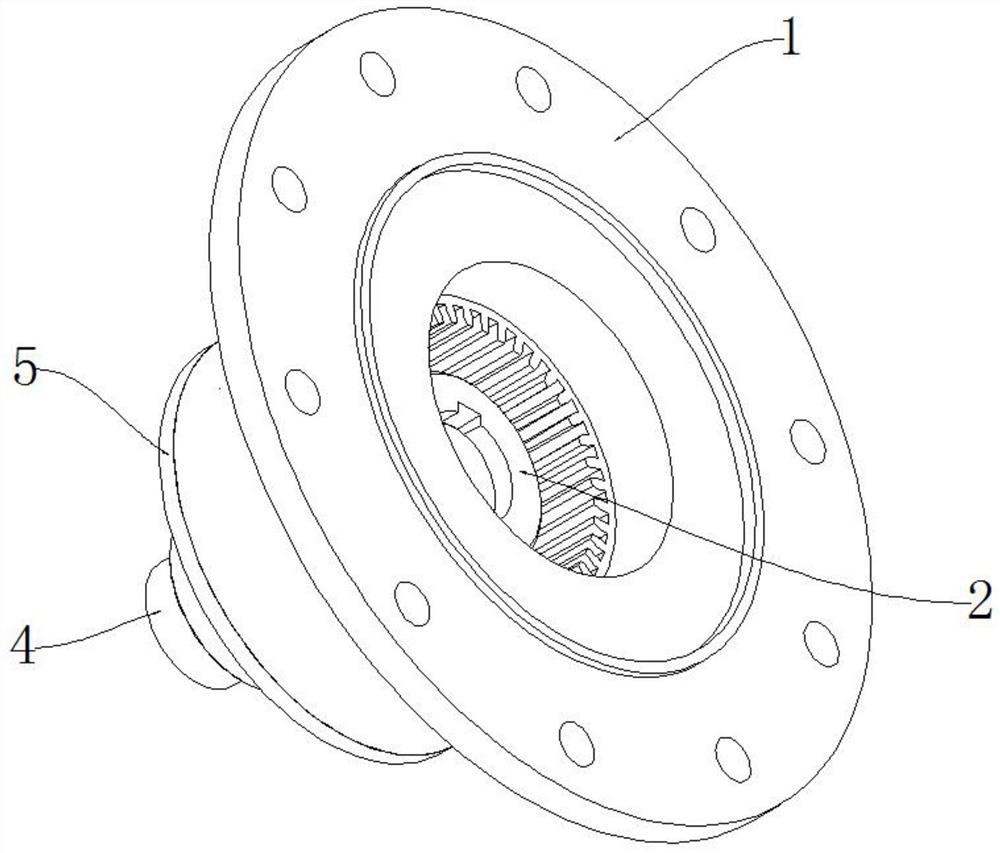

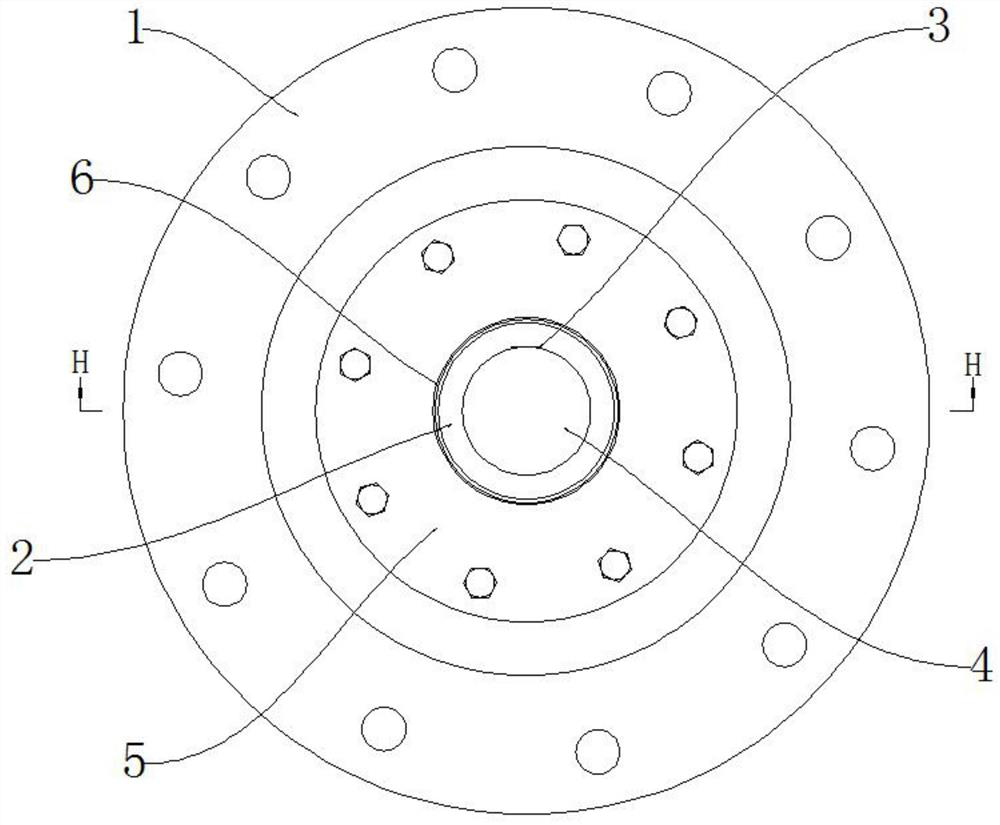

Efficient lubricating gear coupling

A technology of couplings and gears, applied in the field of high-efficiency lubricating gear couplings, can solve the problems of low lubricating efficiency and easy to throw out lubricating oil, and achieve the effects of high lubricating efficiency, high utilization rate and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

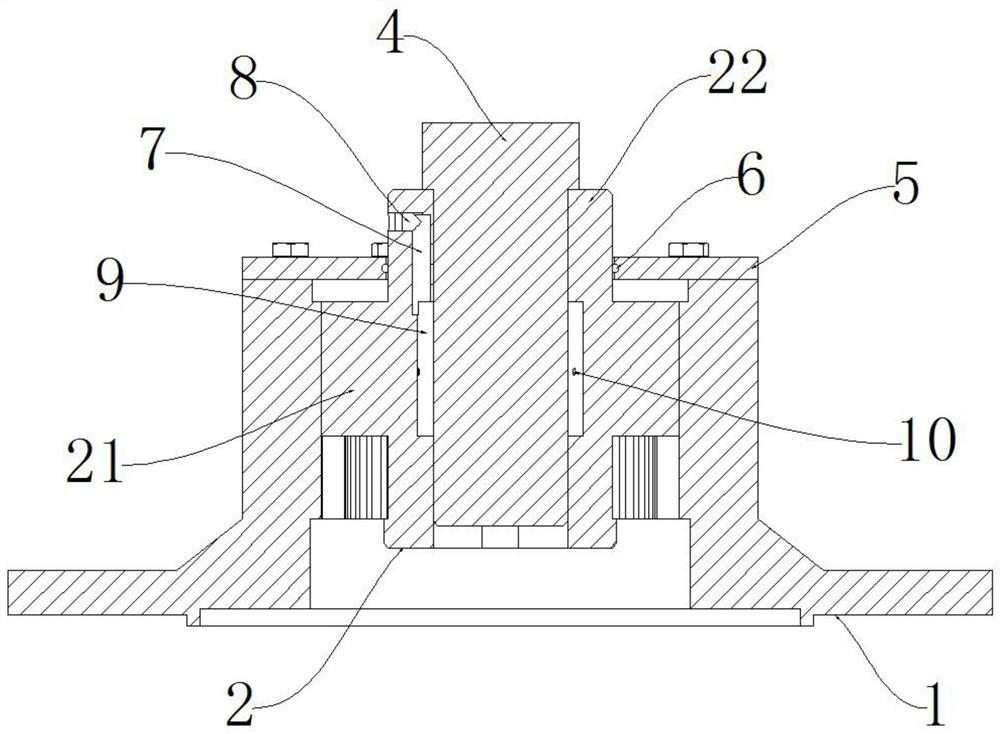

[0024] Figure 8 It shows the cross-sectional structure of the gear coupling in the prior art. It can be seen from the figure that the oil injection part is straight and directly leads to the side of the meshing part. It is difficult for lubricating oil to flow from the oil storage chamber to the other side of the mesh, and the lubrication efficiency is not high; and when the coupling rotates at high speed, once the sealing ring is slightly worn or displaced, the lubricating grease will splash However, it is not only wasteful, but also pollutes the environment and affects peripheral equipment. The temperature of the equipment is generally high during operation, and the oil is flammable, which brings safety hazards. Therefore, the inventor has improved the existing gear coupling.

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com