Novel high-efficiency energy-saving automatic liquid supplementing liquid cooling source equipment

A high-efficiency, energy-saving, liquid cooling source technology, used in lighting and heating equipment, refrigerators, refrigeration components, etc., can solve the problems of heating equipment temperature rise, shortened service life, insufficient cooling liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further described in detail through specific implementation methods:

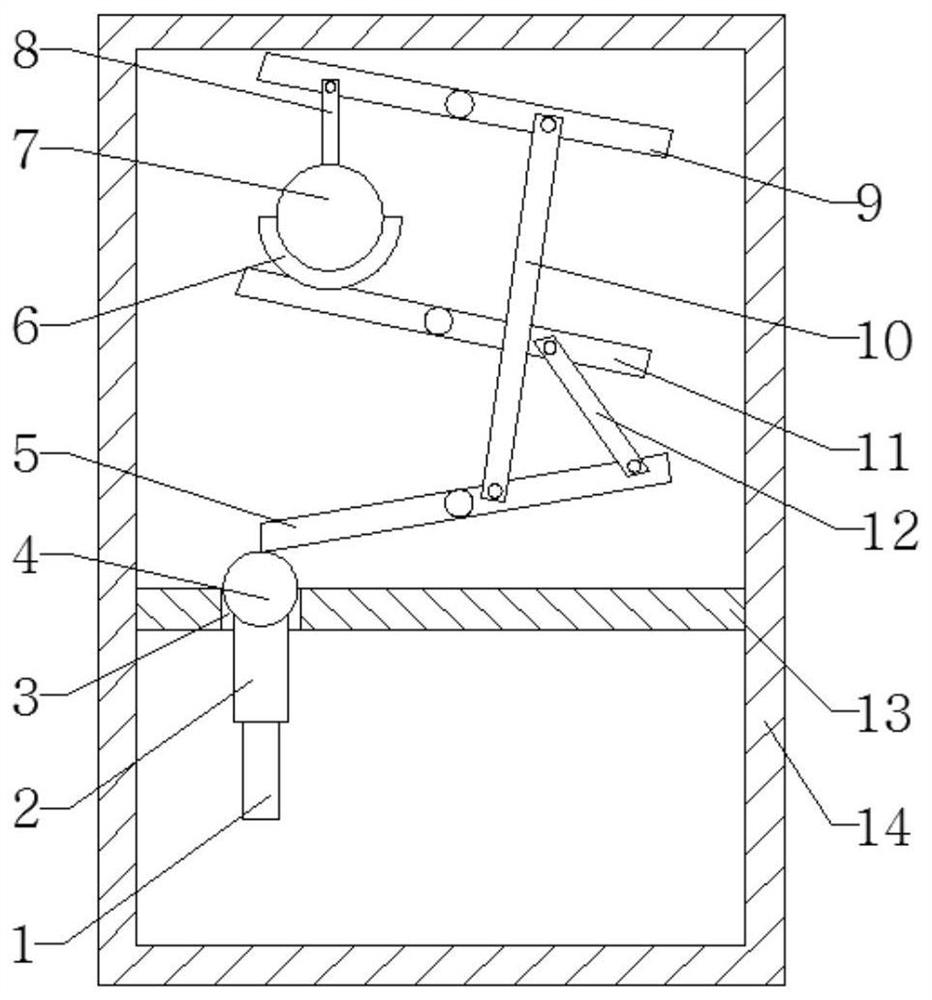

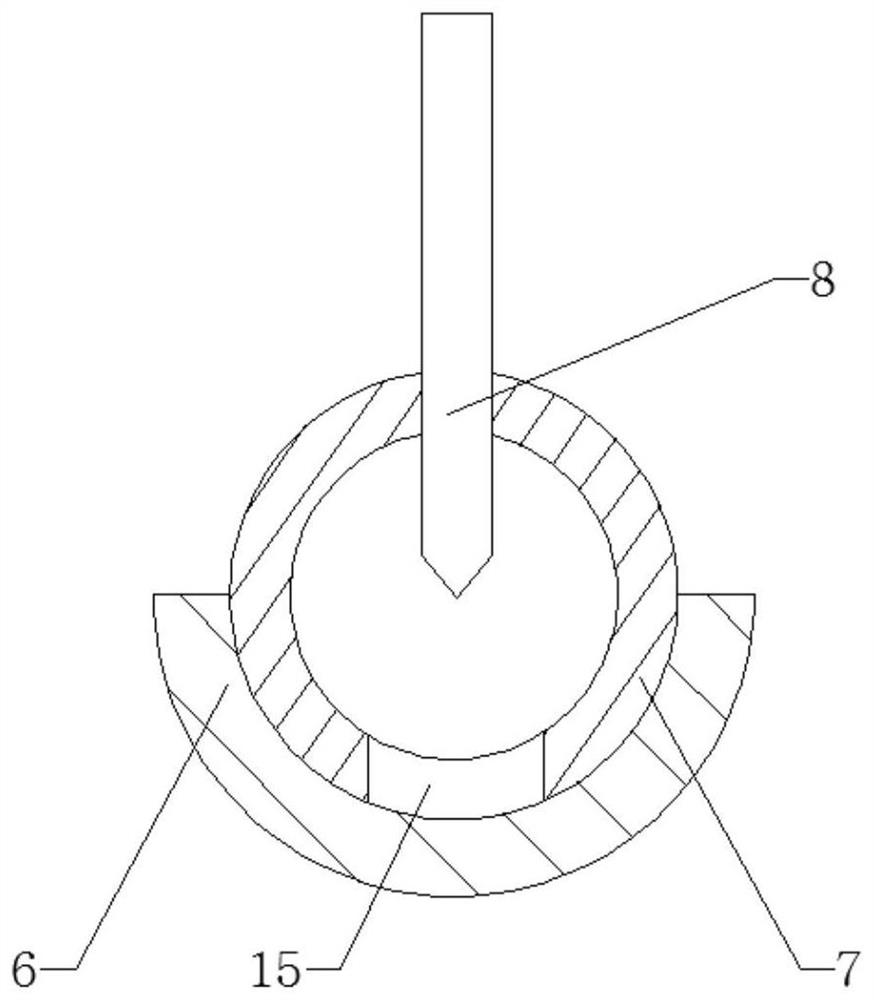

[0016] The reference signs in the drawings of the specification include: chute 1, limit block 2, guide groove 3, floating ball 4, first pendulum bar 5, U-shaped plate 6, liquid replenishment pipe 7, ejector rod 8, third pendulum bar 9. Vertical rod 10, second swing rod 11, connecting rod 12, limit plate 13, water tank 14, liquid replenishment port 15.

[0017] Examples such as figure 1 , a new type of high-efficiency and energy-saving automatic liquid replenishment liquid cold source equipment, including a water tank 14 and a liquid replenishment tank (not shown in the figure), a transverse limit plate 13 is welded on the inner wall of the water tank 14, and the limit plate 13 is provided with a guide groove 3. The inner wall of the water tank 14 is also provided with a vertical chute 1, the chute 1 is vertically slidably connected to the limit block 2, and the top of the limit bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com