Automatic centralized water supply system special for printer

A technology of water supply system and printing machine, which is applied in the direction of printing machine, rotary printing machine, lithographic rotary printing machine, etc. It can solve the problems of unqualified products, frictional heat generation, uncontrolled fountain solution temperature, etc., and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

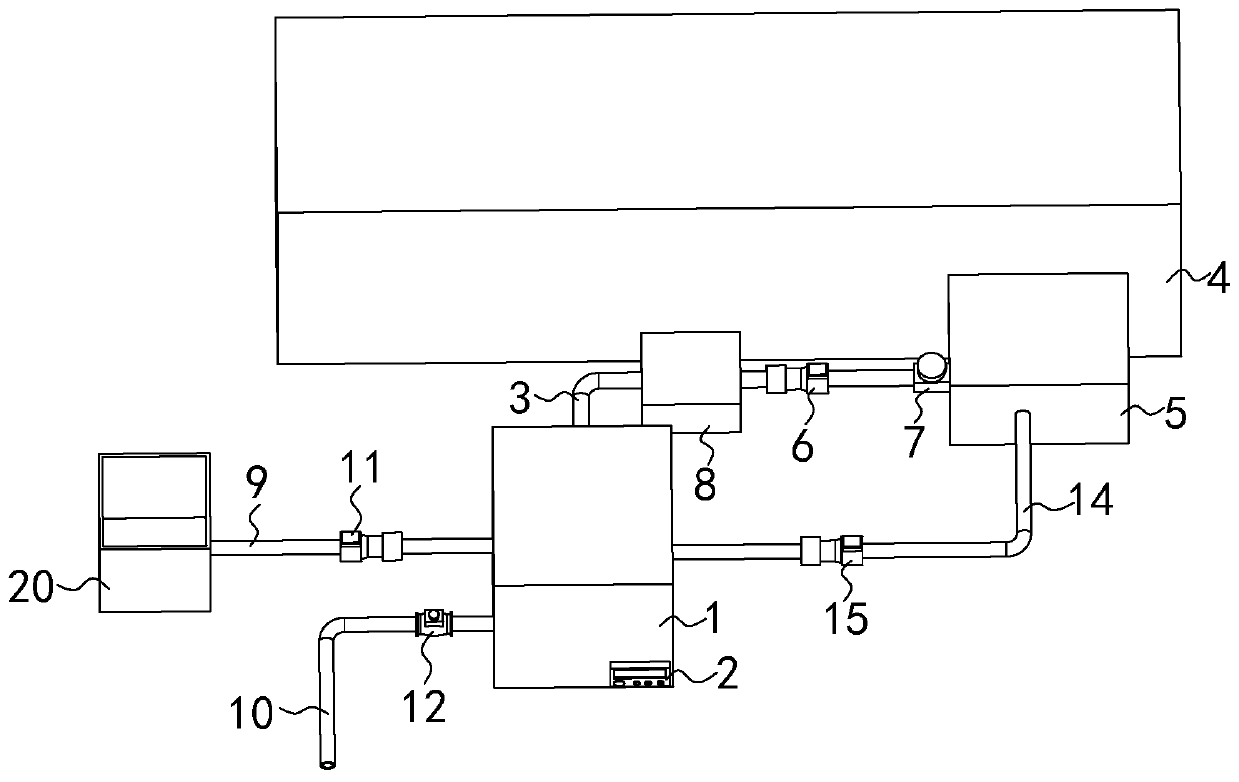

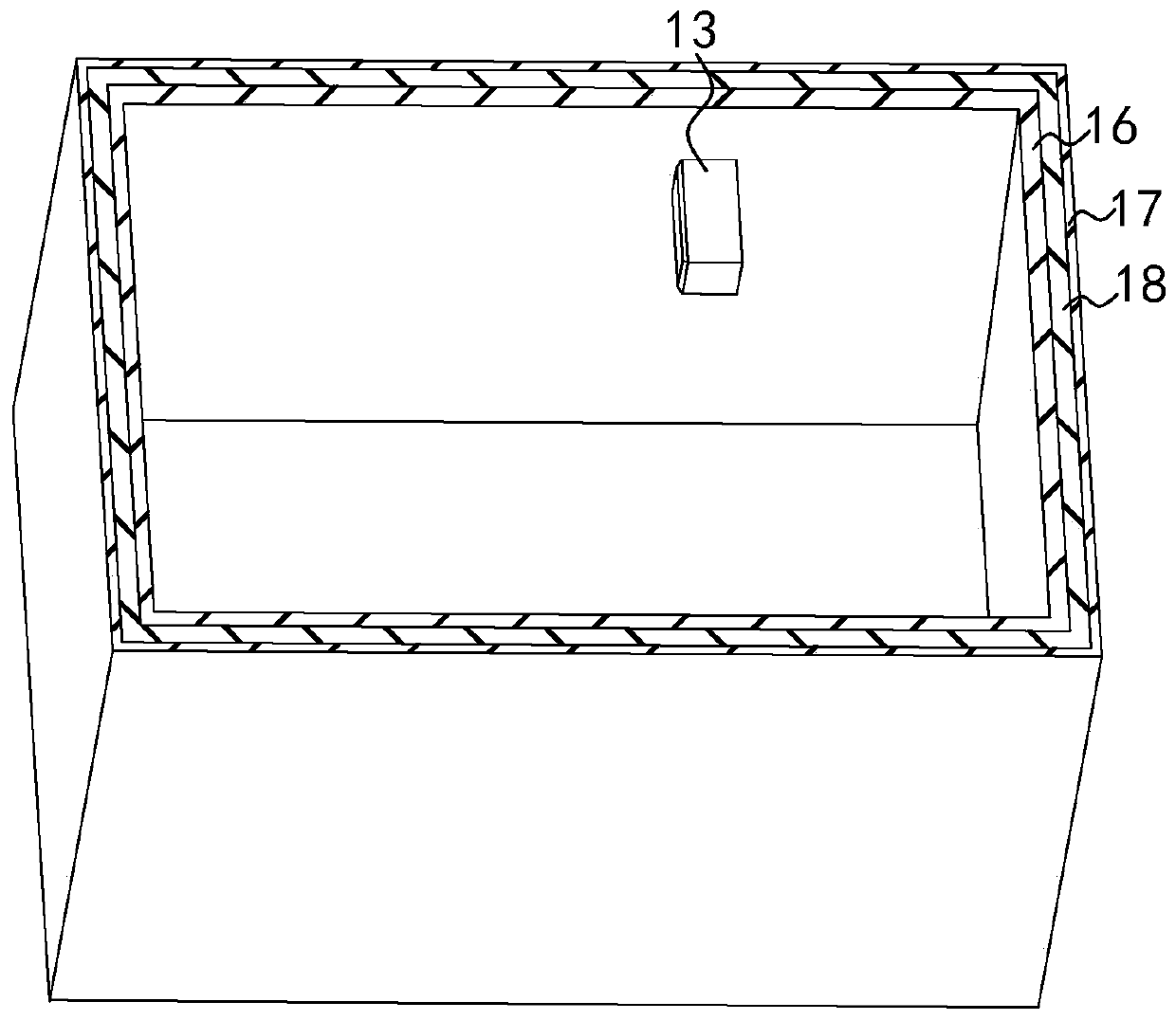

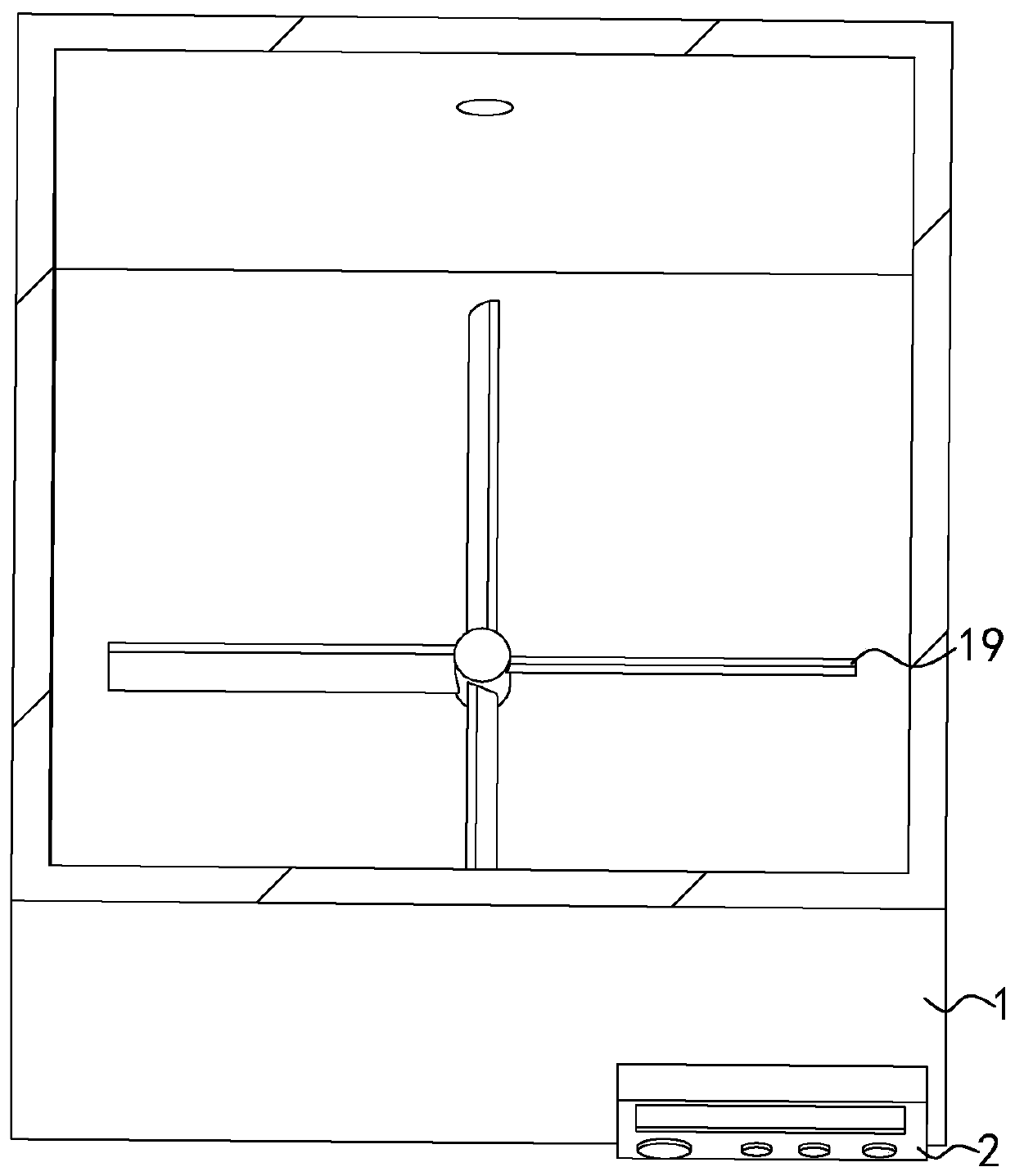

[0035] refer to figure 1 , is a printing machine disclosed in the present invention, a dedicated automatic centralized water supply system, including a dampening working fluid storage tank 1, and a control panel 2 is arranged on the dampening working fluid storage tank 1. The dampening working fluid storage tank 1 is connected with a water inlet pipe 10, which is connected to the tap water pipe after the water inlet pipe 10 is connected with the control valve 12. The tap water is generally underground water, and the water temperature is relatively low. Plate working fluid storage tank 1 is filled with water. The control valve 12 is set as an electric regulating valve, and the electric regulating valve is electrically connected with the control panel 2, and the opening and closing degree of the electric regulating valve can be controlled through the control panel 2, thereby controlling the filling of the dampening working fluid storage tank 1 by the water inlet pipe 10 quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com