packaging bag

A packaging bag and packaging technology, applied in the field of packaging bags, can solve the problem of not being able to be torn neatly, and achieve the effect of excellent storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

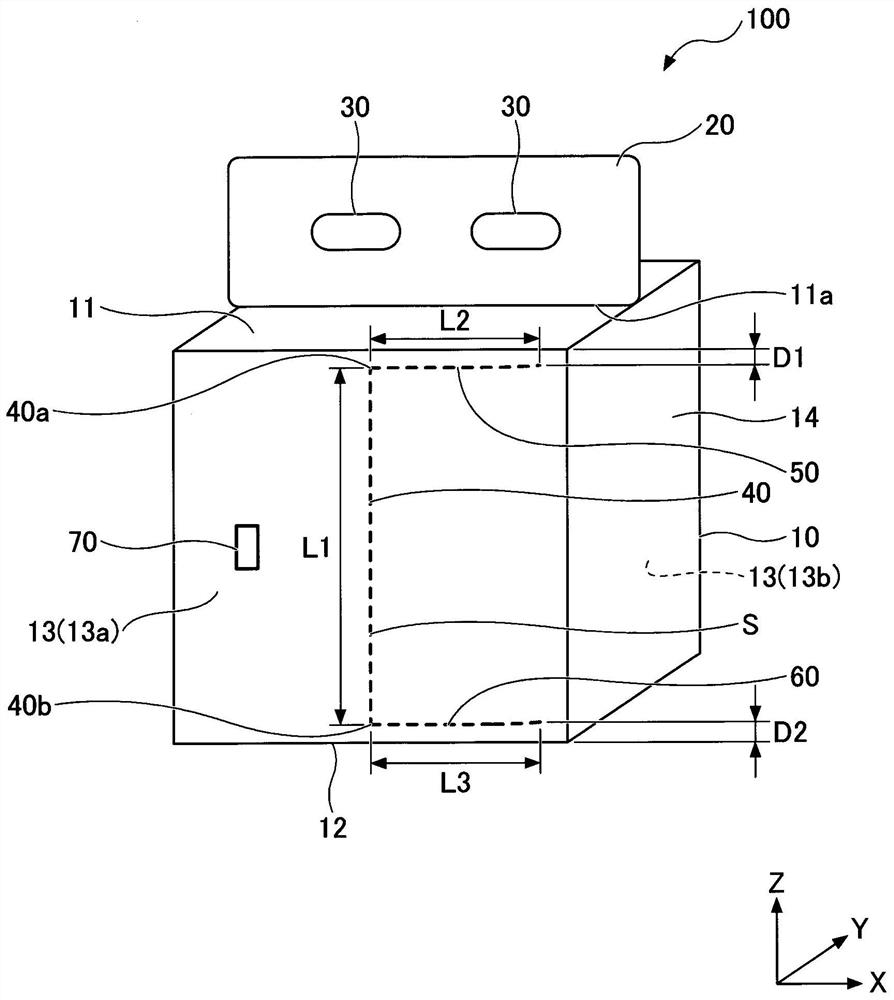

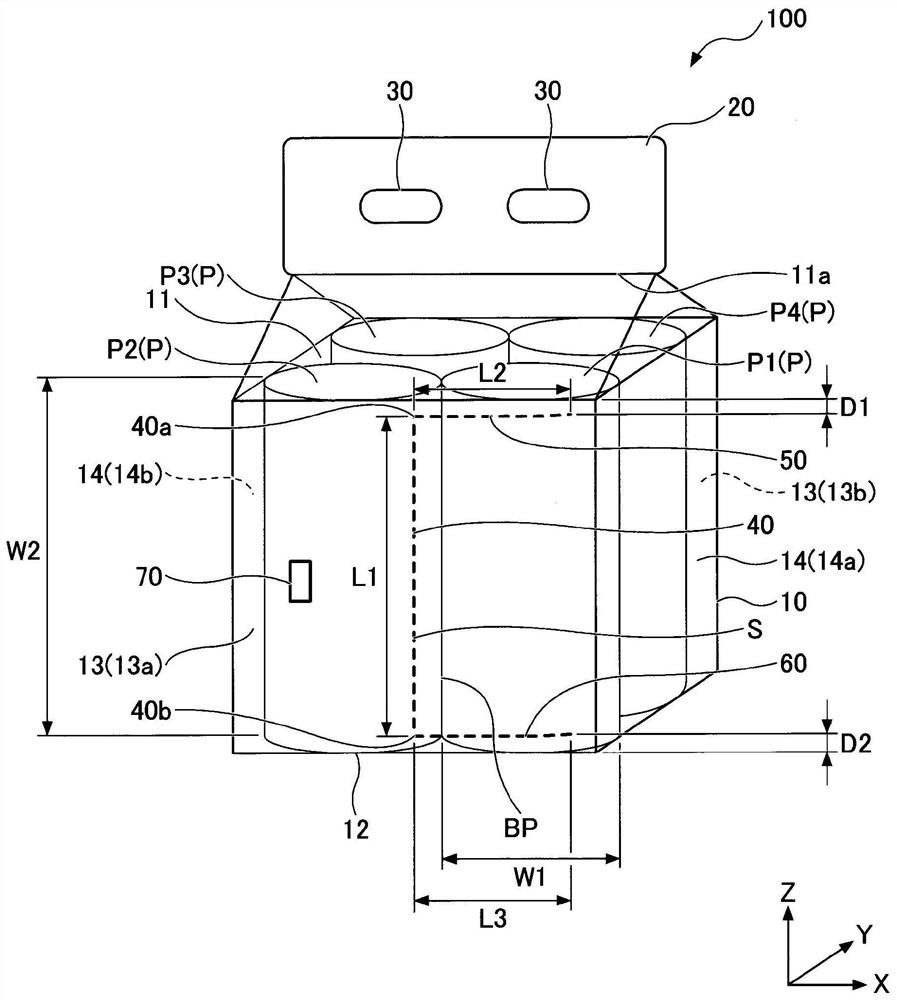

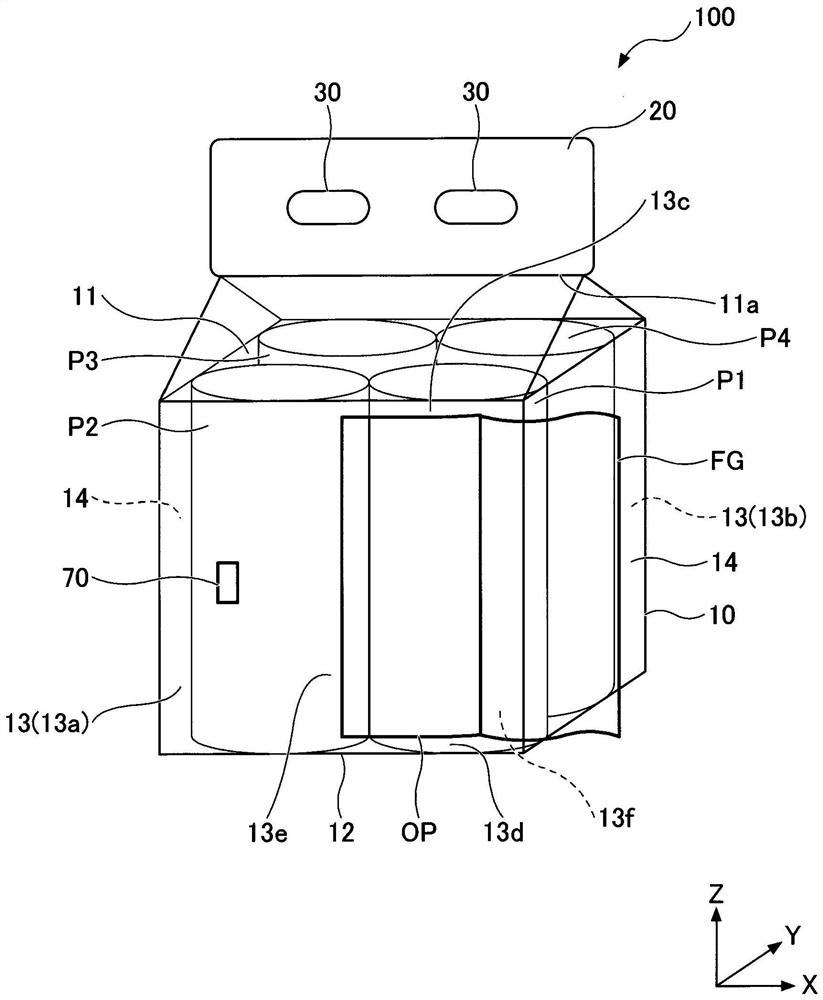

[0135] get ready figure 1 , figure 2 The packaging bag 100 of the first embodiment is shown. In this packaging bag 100 , a first slit 40 extending from the vicinity of the top surface 11 in the vertical direction (Z direction) to the vicinity of the bottom surface 12 is formed on the side surface 13 a of the main body 10 . Further, on the side of the top surface portion 11 of the side surface portion 13a, a second slit 50 extending in the lateral direction (X direction) is formed continuously from the one end 40a of the first slit 40 . In addition, on the side of the bottom surface portion 12 of the side portion 13a, it is continuous with the other end 40b of the first slit 40 and faces the second slit 50 in the vertical direction (Z direction). Extended third slot 60 . In addition, the length L1 of the first slit 40 is set to about 228mm (L1 ratio: about 100%), the length L2 of the second slit 50 is set to about 66mm (L2 ratio: 60%), and the length of the third slit 60 L...

Embodiment 2

[0137] get ready Figure 9 The packaging bag 100 of the second embodiment is shown. In this packaging bag 100, the length L1 of the first slit 40 is set to about 160 mm (L1 ratio: about 70%), the second slit 50 has a base 51, and one end of the second slit 50 is inclined relative to the base 51. Slope portion 52, in addition, the third slit 60 has a base portion 61, and the slope portion 62 in which one end of the third slit 60 is inclined relative to the base portion 61, except that the packaging bag 100 was produced in the same manner as in Example 1, and carried out evaluate. The results are shown in Table 1.

Embodiment 3

[0139] get ready Figure 10 A third embodiment of the packaging bag 100 is shown. In this packaging bag 100, the length L3 of the third slit 60 is set to be shorter than the length L2 of the second slit 50, the length L2 of the second slit 50 is set to about 66 mm (L2 ratio: 60%), and the second The packaging bag 100 was produced and evaluated in the same manner as in Example 1 except that the length L3 of the triple slit 60 was about 33 mm (L3 ratio: about 30%). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com