Unsealing method of plastic package device

A device and packaging layer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor unsealing effect and failure to unseat successfully, and achieve complete chip without damage, complete wiring, and improved unsealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

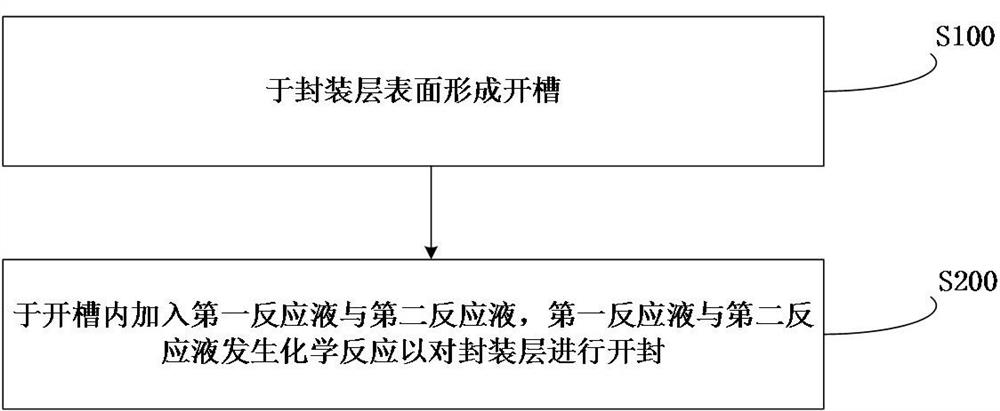

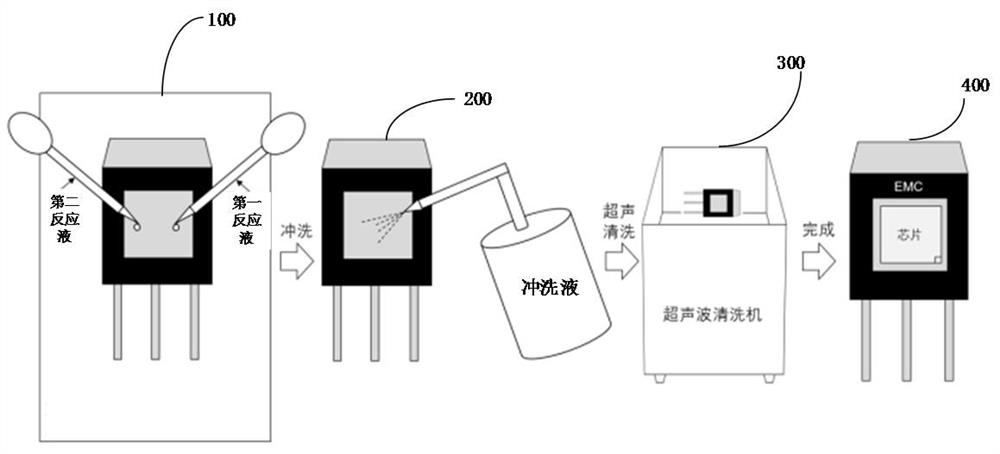

[0085] A method for unsealing a plastic-encapsulated device, comprising:

[0086] (1) Use laser unsealing equipment to irradiate the surface of the encapsulation layer with laser light until the wire bonding is exposed, thereby forming a groove on the surface of the encapsulation layer.

[0087] (2) Drop 1 drop (about 0.1ml) of anhydrous ethylenediamine into the groove formed in the above step (1), and heat the plastic-encapsulated device through a heating device, so that the anhydrous ethylenediamine in the groove of the packaging layer The amine is heated to 150°C; then 1 drop (about 0.1ml) of a mixed acid composed of fuming nitric acid and 98% concentrated sulfuric acid is added dropwise (in the mixed acid, the volume ratio between concentrated sulfuric acid and fuming nitric acid is 1 / 2), the explosive reaction between anhydrous ethylenediamine and fuming nitric acid caused the part of the groove on the surface of the encapsulation layer to be blasted; wash the plastic-en...

Embodiment 2

[0090] A method for unsealing a plastic-encapsulated device, comprising:

[0091] (1) Use laser unsealing equipment to irradiate the surface of the encapsulation layer with laser light until the wire bonding is exposed, thereby forming a groove on the surface of the encapsulation layer.

[0092] (2) Drop 1 drop (about 0.1ml) of anhydrous ethylenediamine into the groove formed in the above step (1), and heat the plastic-encapsulated device through a heating device, so that the anhydrous ethylenediamine in the groove of the packaging layer The amine is heated to 190°C; then 1 drop (about 0.1ml) of a mixed acid composed of fuming nitric acid and 98% concentrated sulfuric acid is added dropwise (in the mixed acid, the volume ratio between concentrated sulfuric acid and fuming nitric acid is 1 / 2), the explosive reaction between anhydrous ethylenediamine and fuming nitric acid caused the part of the groove on the surface of the encapsulation layer to be blasted; wash the plastic-en...

Embodiment 3

[0095] A method for unsealing a plastic-encapsulated device, comprising:

[0096] (1) Use laser unsealing equipment to irradiate the surface of the encapsulation layer with laser light until the wire bonding is exposed, thereby forming a groove on the surface of the encapsulation layer.

[0097] (2) Drop 1 drop (about 0.1ml) of anhydrous ethylenediamine into the groove formed in the above step (1), and heat the plastic-encapsulated device through a heating device, so that the anhydrous ethylenediamine in the groove of the packaging layer The amine is heated to 250°C; then 1 drop (about 0.1ml) of a mixed acid composed of fuming nitric acid and 98% concentrated sulfuric acid is added dropwise (in the mixed acid, the volume ratio between concentrated sulfuric acid and fuming nitric acid is 1 / 2), the explosive reaction between anhydrous ethylenediamine and fuming nitric acid caused the part of the groove on the surface of the encapsulation layer to be blasted; wash the plastic-en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com