Plastic cap

A technology for plastic caps and container mouths, which is applied in capping, bottle/container caps, and capping containers tightly with caps, etc. It can solve the problems of increased cap height and resin weight, and achieve resin weight reduction and cost reduction , Effective use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention is described by the following examples.

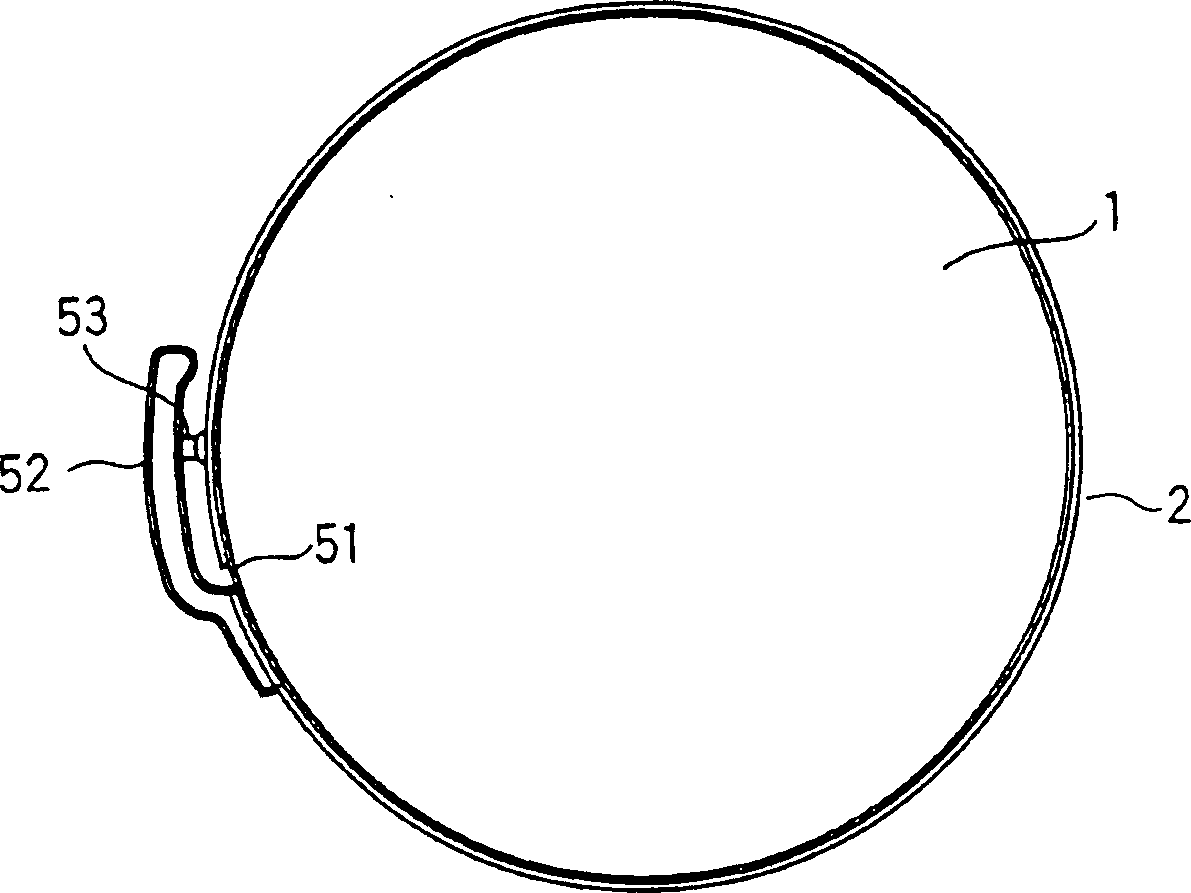

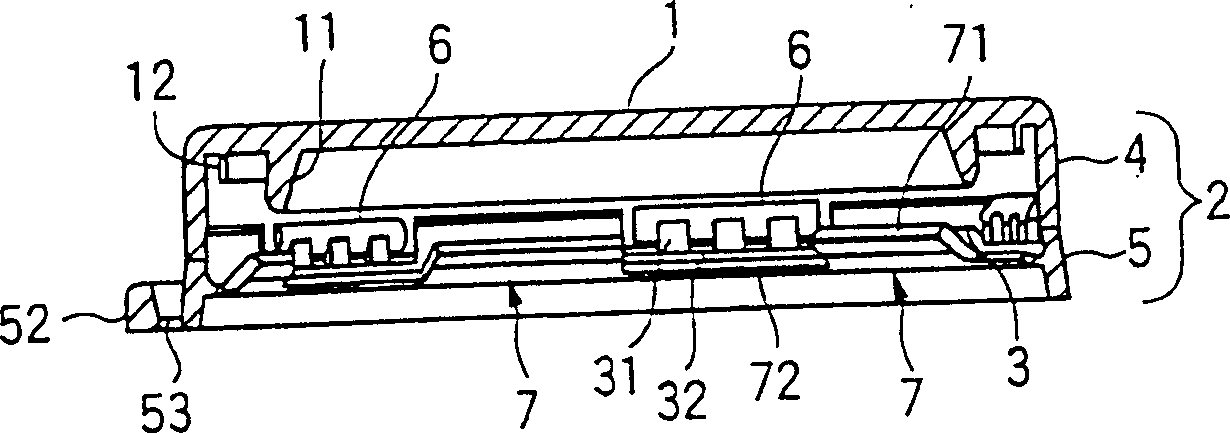

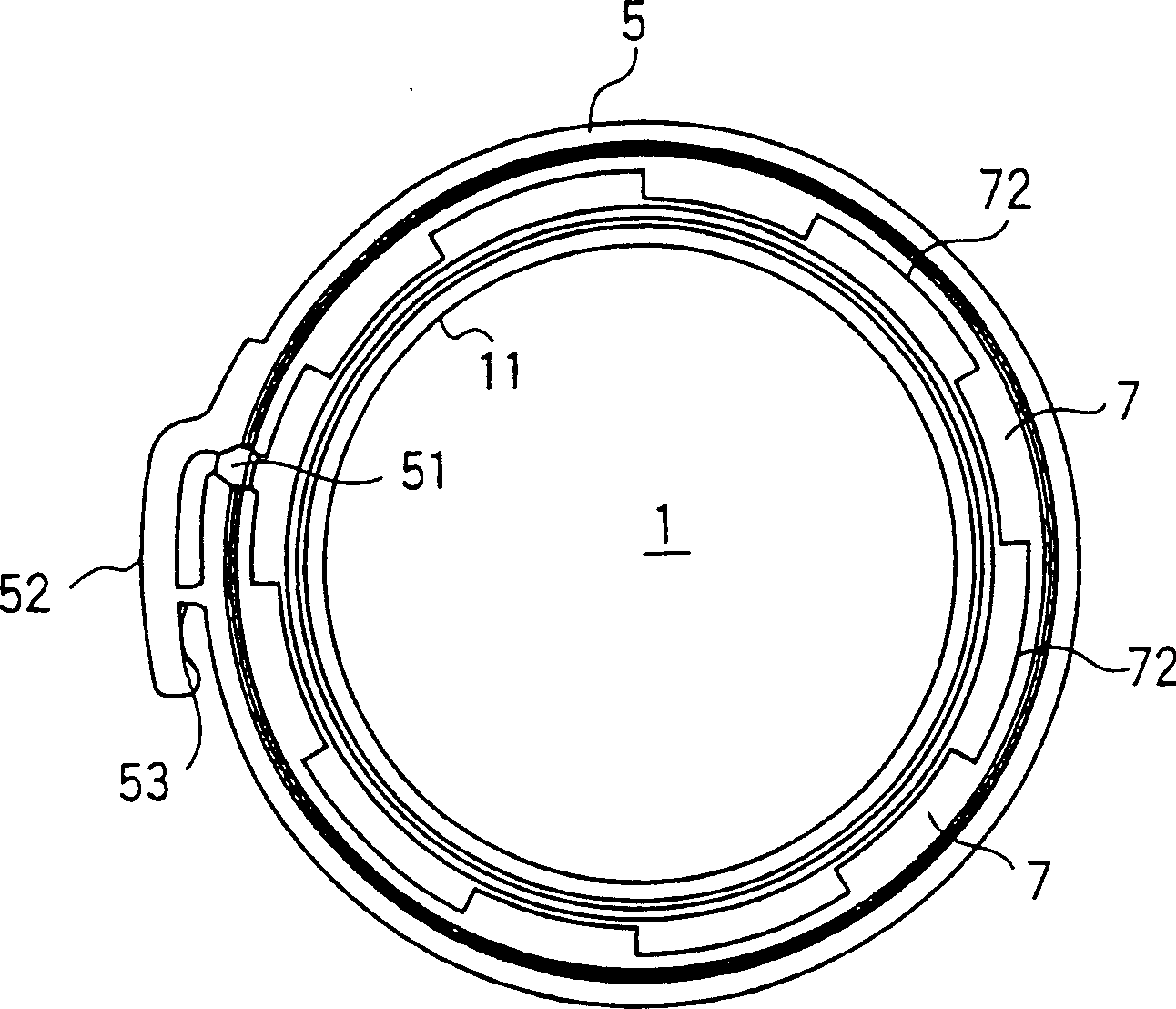

[0037] Generally speaking, the plastic cap of the present invention includes a top plate 1 provided with a sealing portion engaged with the mouth of the bottle, a skirt portion 2 extending downward from the top plate 1 and a tear-off portion 3 arranged around the skirt 2 . Due to the tear 3, the skirt 2 is divided into an upper lid part 4 and a lower opening strip 5 for resealing.

[0038] Such as Figures 7 to 9 Shown, the neck 8 of the bottle that installs cap of the present invention is provided with the top 81 of mouth, the inner surface 82 of mouth, the outer peripheral surface 83 of mouth, the jaw portion 84 that engages with lid and supporting ring 85, ring 85 protect the opening belt at the same time.

[0039] The sealing portion provided on the inner surface of the top plate 1 may be any known sealing structure. In this particular example, it includes an inner ring 11 engaging the inner surface 82 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com