Measuring device for ascertaining measurand of measurement gas

A measuring device and a technique for measuring parameters, which are applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves for material analysis, and optical means for material analysis, etc., can solve problems such as large interference, reduce interference noise, and realize length adjustment , the effect of attenuating the frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

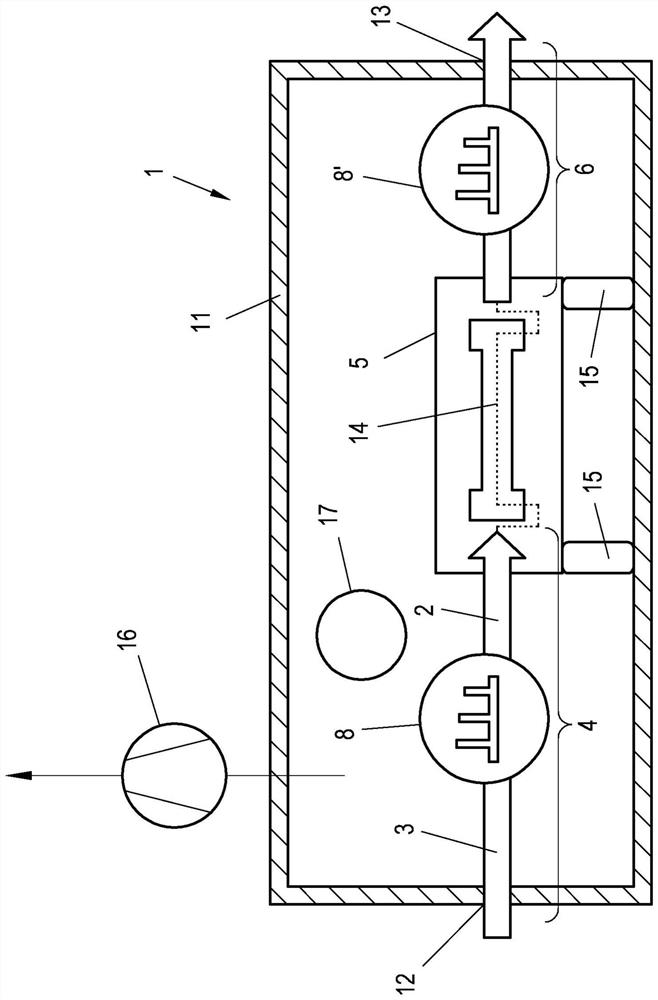

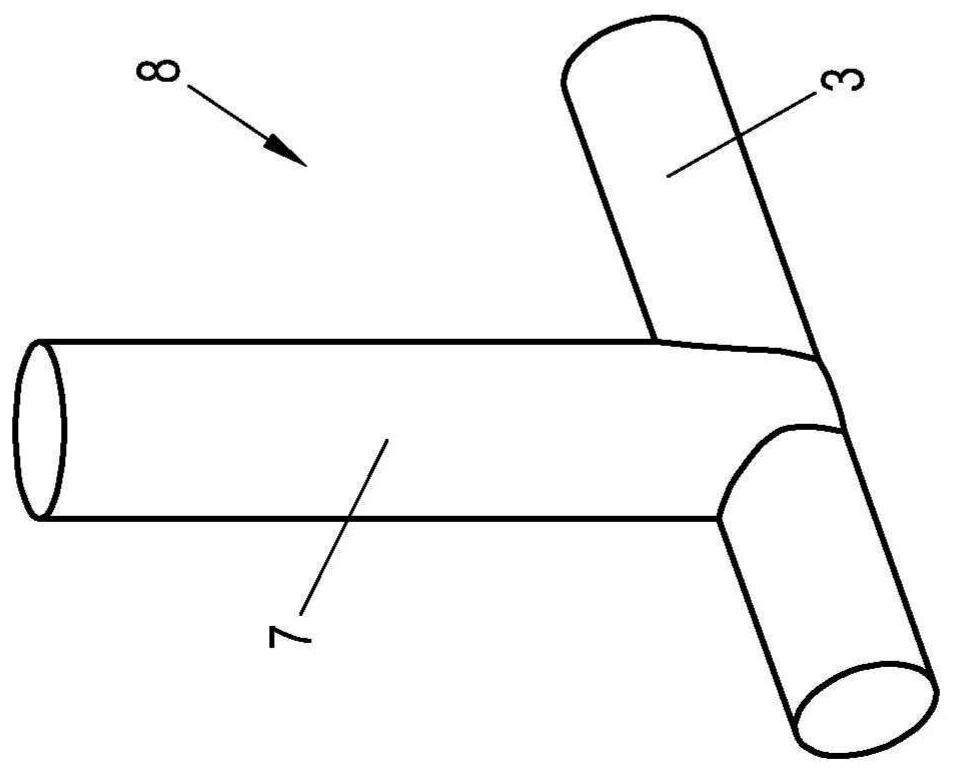

[0040] exist figure 1The main elements of the measuring device 1 are schematically shown in . The important components of the measuring device 1 are arranged in a protected manner in the housing 11 , wherein the measuring gas 2 is supplied to the measuring device 1 in the measuring gas inlet 12 and the measuring gas 2 is again in the measuring gas outlet 13 after the measurement Leave the measuring device 1. The path of the measuring gas 2 in the interior of the measuring device 1 is defined by a flow channel 3 which extends from the measuring gas inlet 12 to the measuring gas outlet. The flow channel 3 conducts the measuring gas 2 over a photoacoustic measuring cell 5 in which the measuring gas is excited with pulsed or modulated laser radiation in a known manner.

[0041] The flow channel 3 can thus be divided into three sections: the feed line 4 from the measuring gas inlet 12 to the measuring cell 5 , the flow path 14 leading through the measuring cell and defining its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com