Hedge shears with compound sensor and trimming method thereof

A pruning method and sensor technology, applied in the field of hedge trimming, can solve the problems of difficulty in trimming hedges, high labor intensity, low efficiency, etc., and achieve the effects of improving pruning efficiency, expanding pruning range, and protecting saw teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

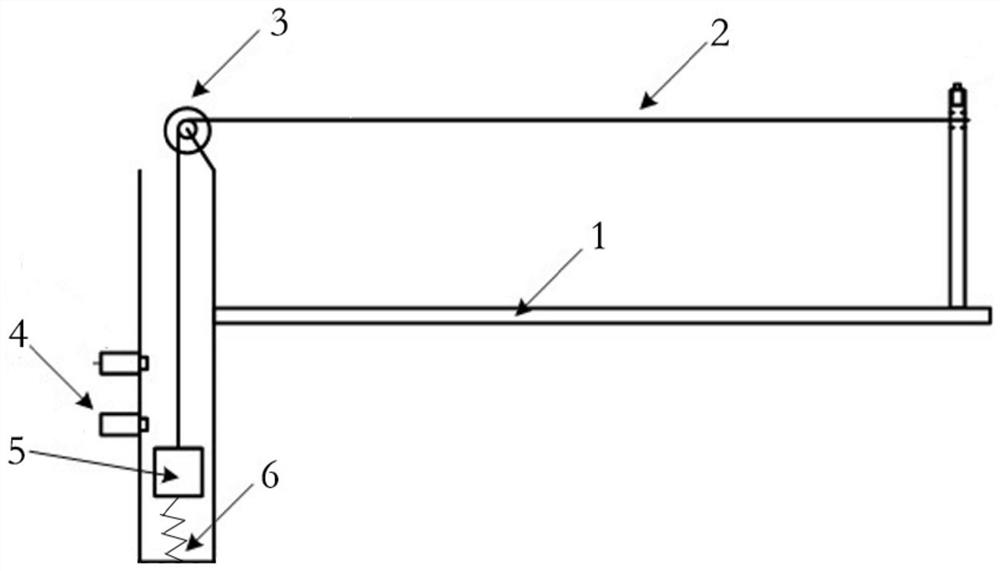

[0026] like figure 1 , The hedge shears compound having the inductor, which is mounted on a carrier, comprising a lateral longitudinal hedge shears and left direction can be the direction of motion and a resistance detecting means for detecting resistance to lateral trimming hedge shears are; the said resistance detecting means comprises one end with the transverse hedge shears spring fixedly connected to 6, the barrier sheet 5 and the other end of the spring fixedly connected with the blocking lines of force receiving plate fixedly connected to 2, the lateral hedge shears articulated roller 3, and a plurality a blocking plate for detecting the position sensor 4; the bypass line roller force, the transverse end thereof remote from the barrier sheet hedge shears is fixedly connected.

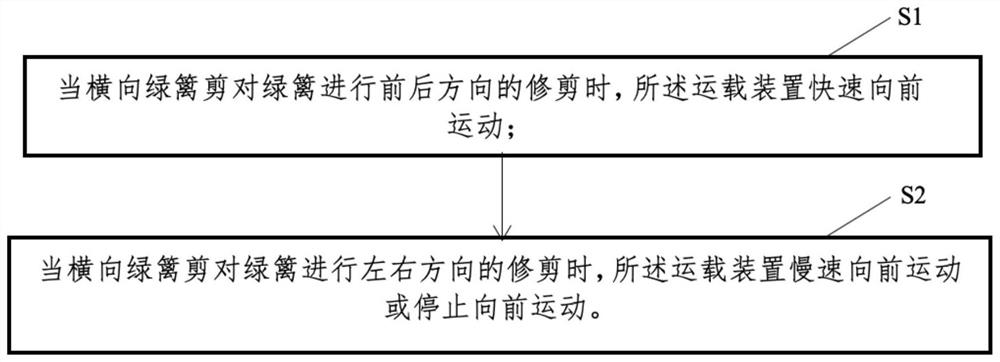

[0027] When the hedge shears lateral motion of the front-rear d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com