Automobile steering pull rod assembly pre-pressing necking machine

A technology of steering tie rod and closing machine, which is applied to vehicle parts, feeding devices, positioning devices, etc., can solve the problems of high labor intensity, product stability and consistency cannot be guaranteed, steering tie rod torque illusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

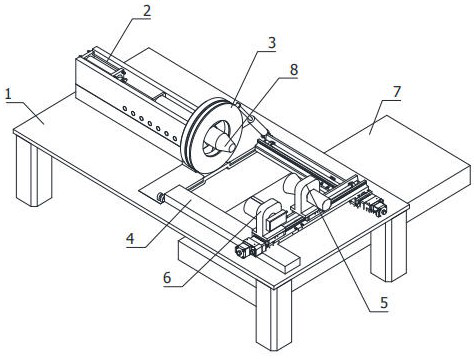

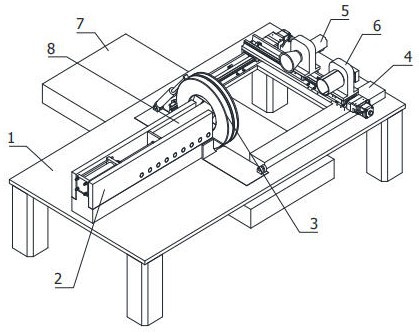

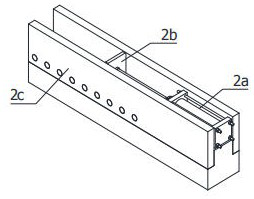

[0038] refer to Figure 1 to Figure 10 As shown in the figure, a pre-pressing closing machine for steering rod assembly of an automobile includes a working table 1, a pushing mechanism 2, a clamping mechanism 3, a two-way moving mechanism 4, a spinning mechanism 5, an end clamping mechanism 6 and a feeding mechanism 7. Pushing mechanism 2, clamping mechanism 3 and two-way moving mechanism 4 are all installed on the top of workbench 1, clamping mechanism 3 is located at the discharge end of pusher mechanism 2, and workbench 1 is provided with a discharge port for bidirectional movement The mechanism 4 is located at the blanking port, the two-way moving mechanism 4 has two working ends, the spinning mechanism 5 and the end clamping mechanism 6 are respectively located at the two working ends of the two-way moving mechanism 4, and the feeding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com