Machine tool

A technology of machine tools and racks, which is applied in the field of mechanical equipment to achieve the effect of improving service life, ensuring sealing effect and tight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

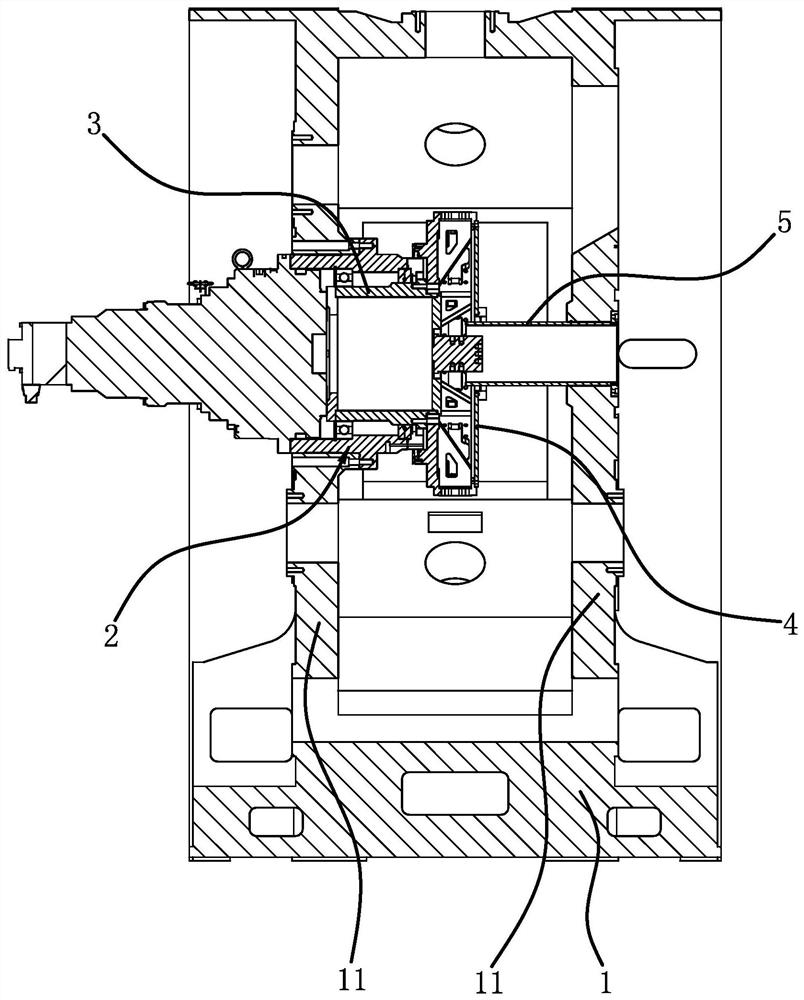

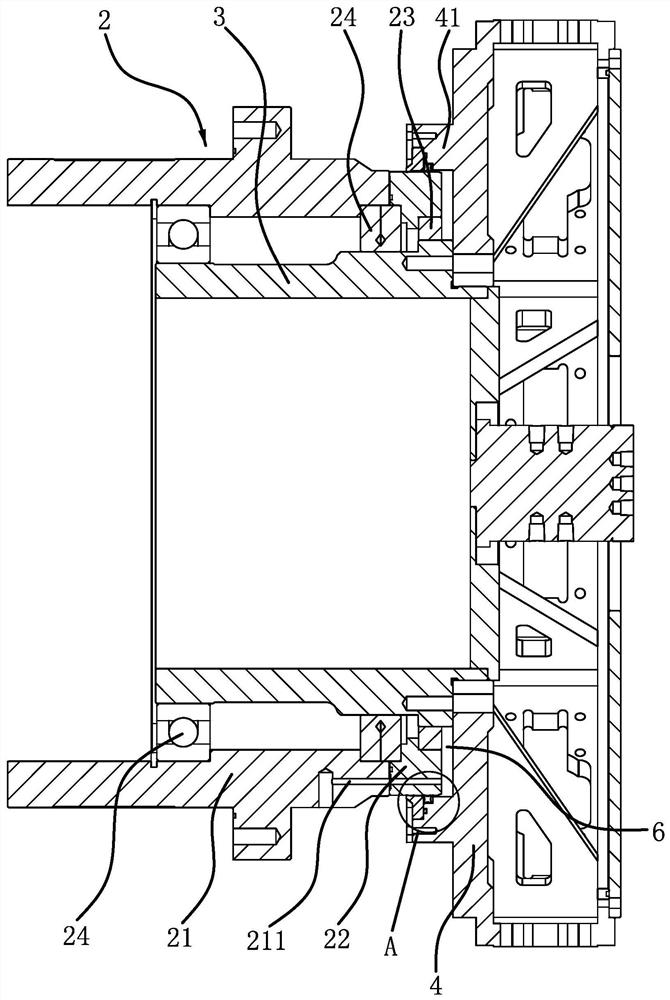

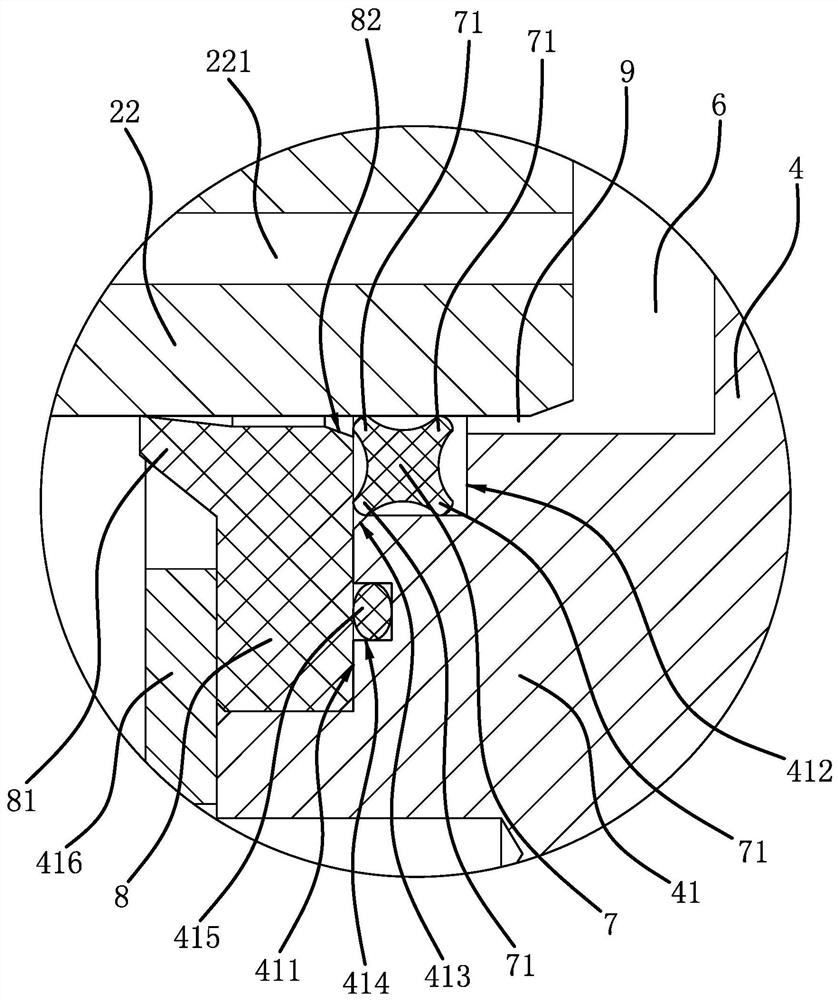

[0027] like figure 1 , figure 2 As shown, a machine tool includes a frame 1, a turntable, a fixed seat 2, a main shaft 3, a sub-disc 4 and a support sleeve 5. Located between the two side plate parts 11, the fixing seat 2 includes a cylindrical seat body 21 and an annular bearing cover 22, the seat body 21 is horizontally fixed on one of the side plate parts 11, and one end of the seat body 21 extends into both sides Between the plate parts 11, the main shaft 3 is installed in the seat body 21, and a bearing 24 is installed between the two, so that the main shaft 3 can rotate, and the bearing cover 22 is fixed on the end of the seat body 21 protruding in, and the bearing 24 is positioned. , the auxiliary disk 4 is vertically arranged, one side of the auxiliary disk 4 is fixed to the end of the main shaft 3, and the other side is connected to the other side side plate 11 through the support sleeve 5. At this time, the end surface of the bearing cover 22 is in contact with the...

Embodiment 2

[0032] This machine tool is basically the same as Embodiment 1, the difference is that the sealing ring 7 and the dustproof ring 8 are all arranged on the bearing cover 22, that is, the first step 411 and the second step 412 are all set at the end of the bearing cover 22, and also have Better sealing effect.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap