Pipefitting die with runner without retardation and forming method thereof

A molding method and a technology for pipe fittings, which are applied to household appliances, tubular objects, and other household appliances, can solve problems such as high stress, and achieve the effects of ensuring production efficiency, broad market prospects, and industrial development advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Describe below in conjunction with above accompanying drawing, but at least should not be limited to following embodiment of the present invention:

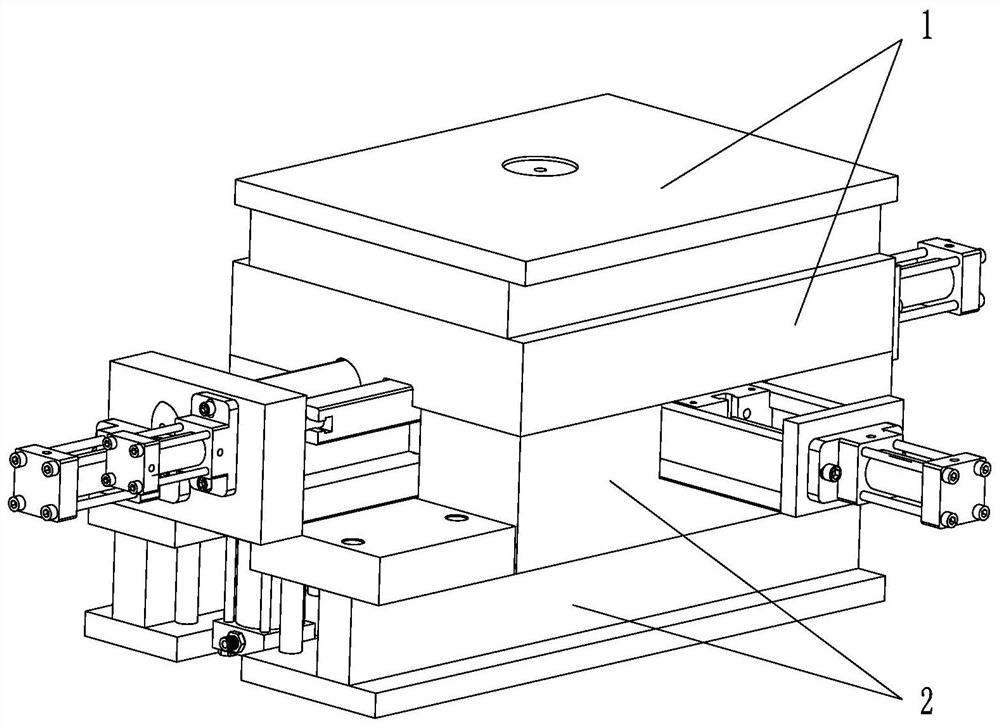

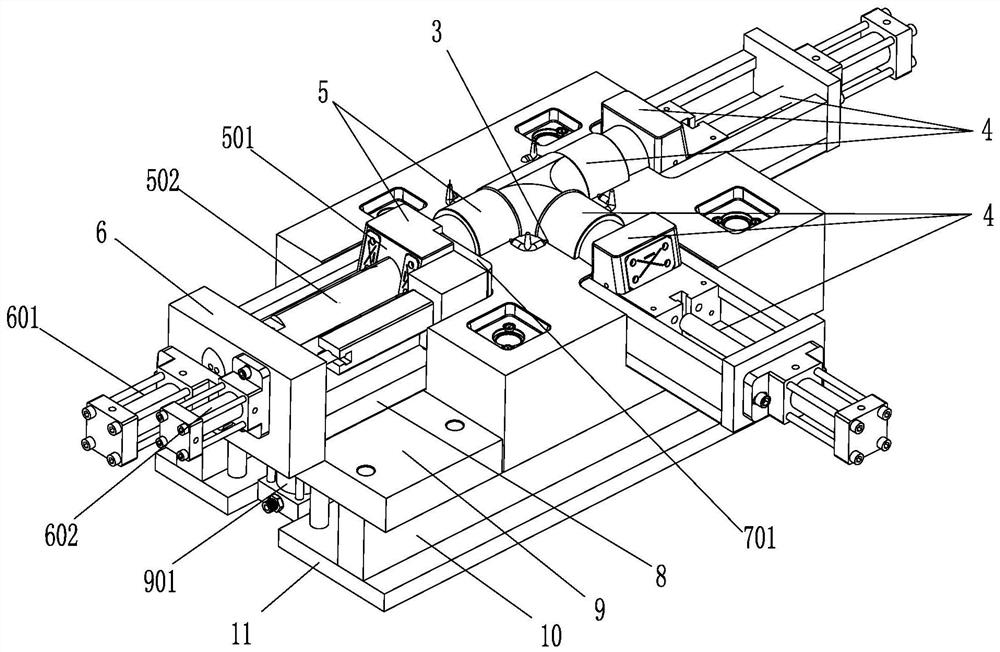

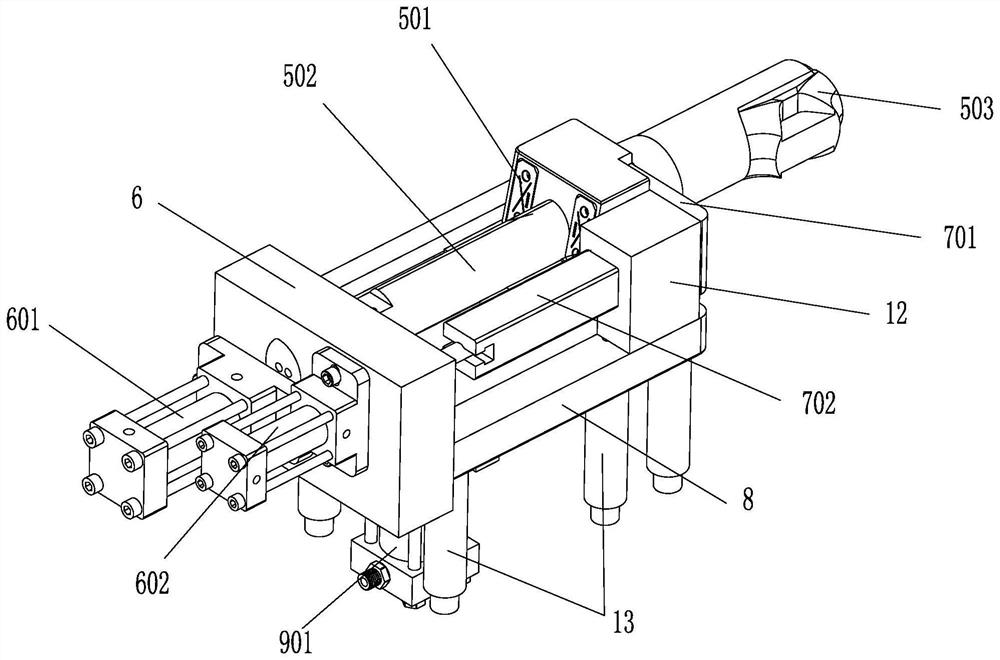

[0036] See attached figure 1 to attach Figure 9 , firstly provide a pipe fitting mold with no blockage in the flow channel, specifically as attached figure 1 Straight tee flow path unrestricted pipe fitting mold shown, and see attached figure 2 , which includes a movable mold 2 matched with its fixed mold 1 and a cavity 3 formed between the fixed mold 1 and the movable mold 2. The cavity 3 is provided with corresponding The two permanent core slider combinations 4 arranged on the cavity 3 and one main core slider guide rail in the present invention cooperate with the action unit, and the two core slider combinations 4 and one main core slider The block guide rails cooperate with the action units to be arranged on different sides of the movable mold 2, and its position distribution can be found in the attached figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com