Tubular connecting piece for cast-in-place concrete wall and heat preservation plate with tubular connecting piece

A technology of concrete walls and connectors, applied in the direction of insulation, walls, building components, etc., can solve the problems of the decline of wall insulation performance, achieve the effects of reducing heat loss, improving insulation performance, and reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

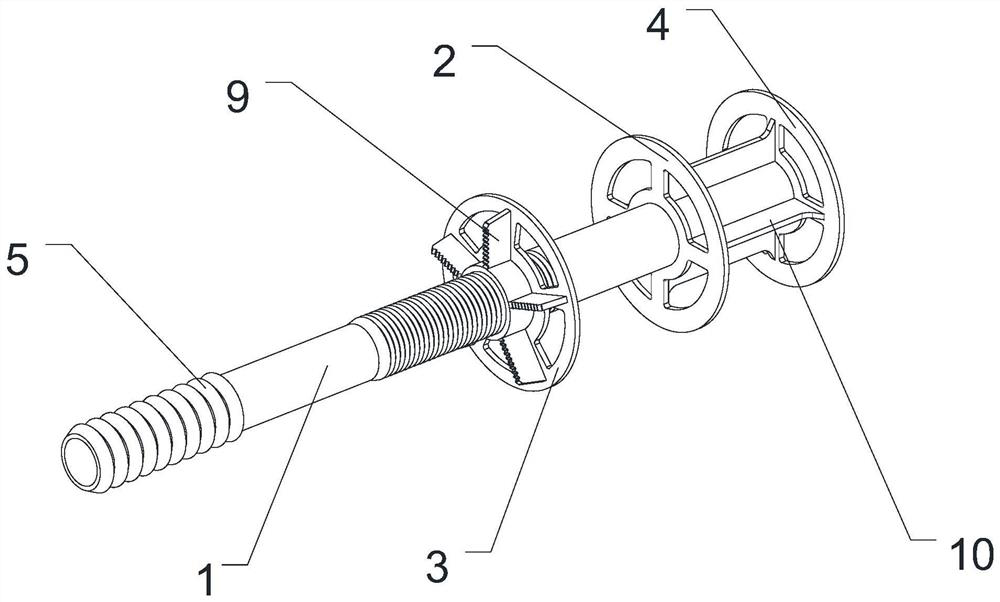

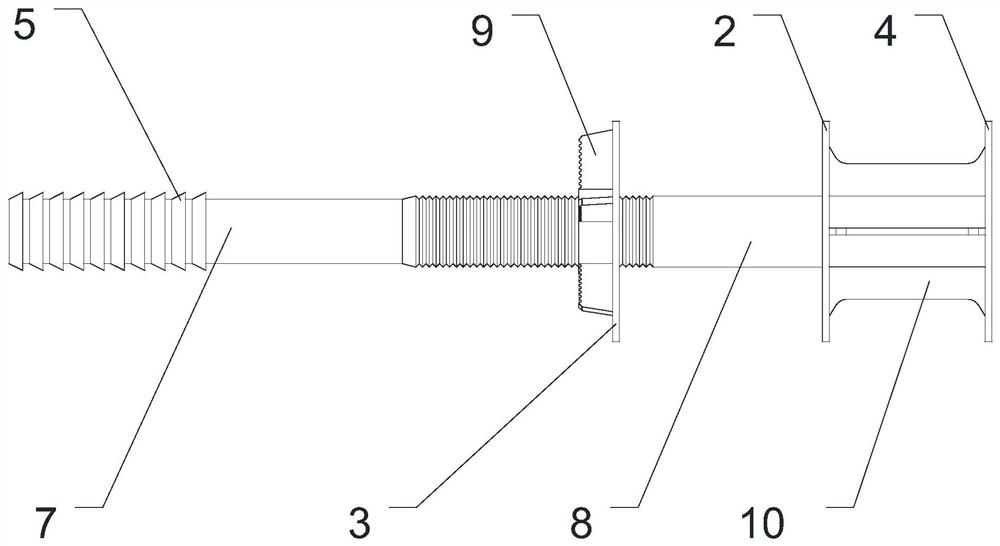

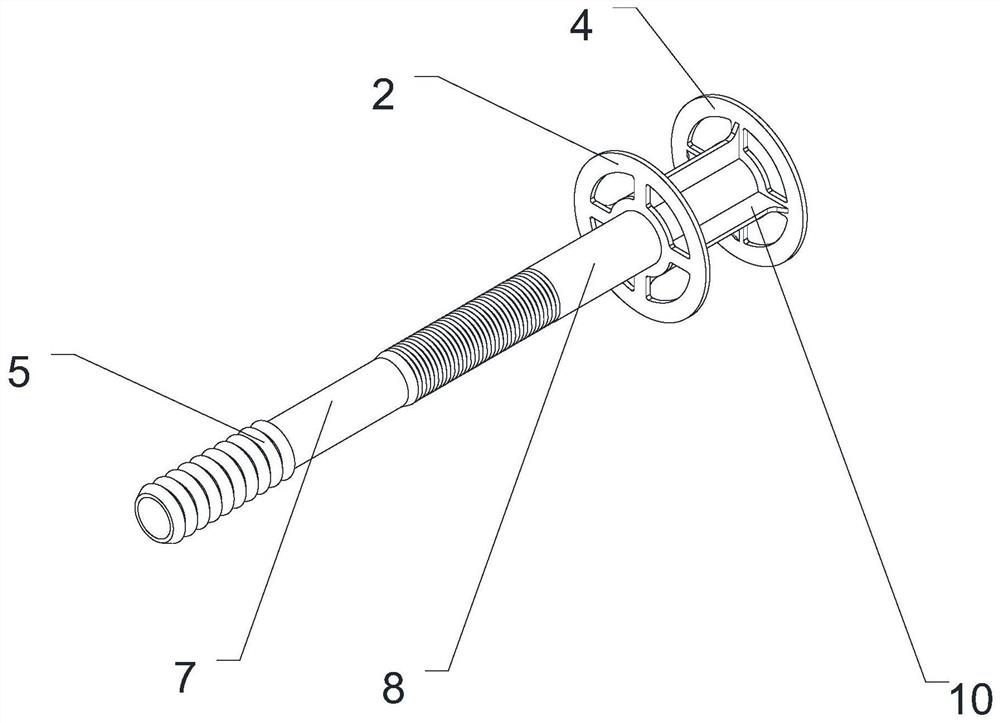

[0042] Such as Figure 1-4 As shown, the tubular connector for cast-in-place concrete walls includes a pipe body 1, the axial passage of the pipe body 1 runs through the pipe body 1 to form openings at both ends of the pipe body 1, and the outer wall of the pipe body 1 is provided with a first stop Sheet 2 and the second limiting sheet 3. When the present invention is in use, the pipe body 1 passes through the insulation board, and the two ends respectively lean against the inner formwork and the outer formwork to support the inner and outer formworks. The fastening of pull bolts realizes the fixation of the inner and outer templates. There is no need to make special holes on the insulation board when setting the pull bolts, which reduces the number of through holes on the insulation board, reduces heat loss, and improves the insulation performance of the wall. The first limiting piece 2 and the second limiting piece 3 sandwich the insulation board in the middle, keep the po...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that the end piece 4 is fixedly connected with the tube body 1, the first limiting piece 2 is integrally formed with the tube body 1, the outer wall of the tube body 1 is provided with a buckle structure, and the second limiting piece The piece 3 is detachably connected with the tube body 1 through a buckle structure. The embedded structure 5 is a bump. The outer wall of the pipe body 1 is provided with an embedded structure 5, and the length along the axial direction of the pipe body 1 is 8 cm.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that the outer wall of the tube body 1 is provided with a barb structure, and the second limiting piece 3 is connected with the tube body 1 through the barb structure. The embedded structure 5 is a barb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com