Clamping piece installation accessory

A technology of auxiliary parts and clips, which is applied in the field of clip installation accessories, can solve the problems of anchorage failure, difficulty in ensuring the distance between clips, deep bite marks, etc., and achieve the effects of simple operation, improved reliability and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

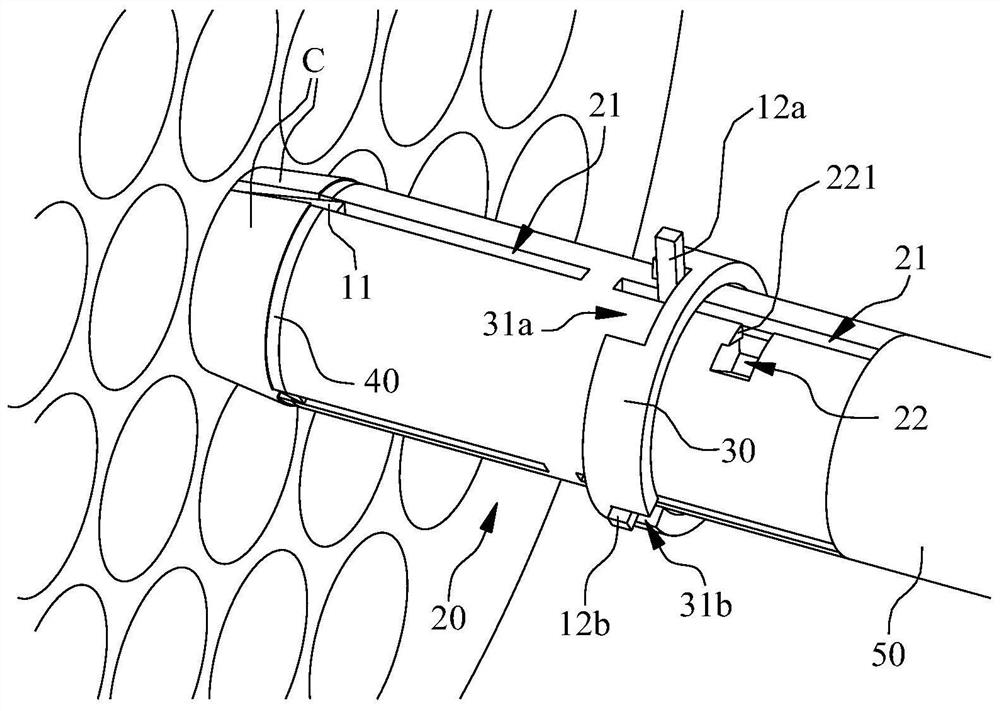

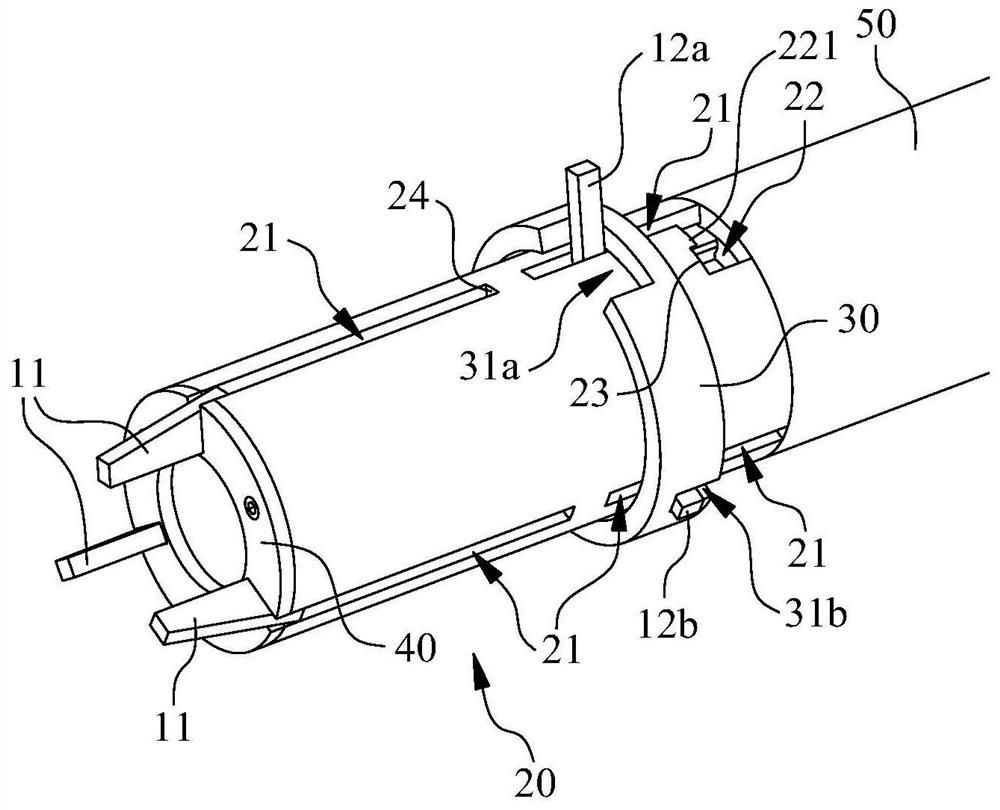

[0019] The specific implementation manner of the present invention will be further described in detail below by describing the embodiments in conjunction with the accompanying drawings.

[0020] For ease of description, the front side or front end adjacent to the clip C is defined, and the back side or rear end away from the clip C is defined.

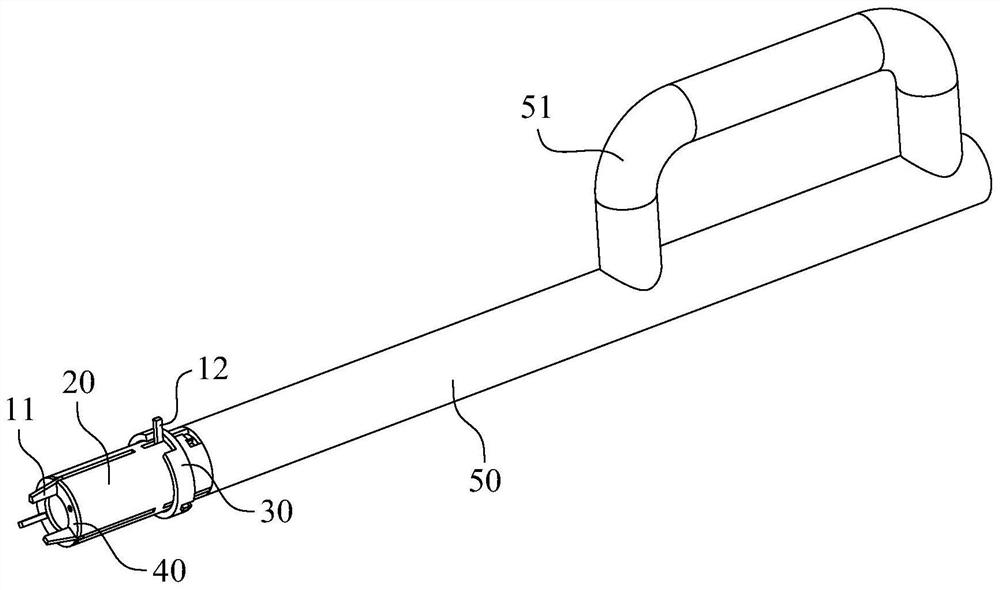

[0021] A clip installation accessory, including a tube base 20 with a separator 11 symmetrically arranged in the circumferential direction, the tube base 20 and the separator 11 form a position-limiting displacement fit along the tube length direction of the tube base 20, and the separator 11 extends to the tube There is a displacement between an overhang position outside the tube end of the base 20 and a retracted position retracted into the tube base 20 . Such as figure 2 As shown, when the separator 11 is in the overhanging position, it is inserted between the clips C, which can ensure the minimum distance between two adjacent cli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com