clip mounting accessories

A technology of accessories and clips, applied in the field of clip installation accessories, can solve the problems of anchoring failure, deep bite marks, and difficulty in ensuring the gap between clips, and achieves the effects of improving reliability, simple operation and convenient positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

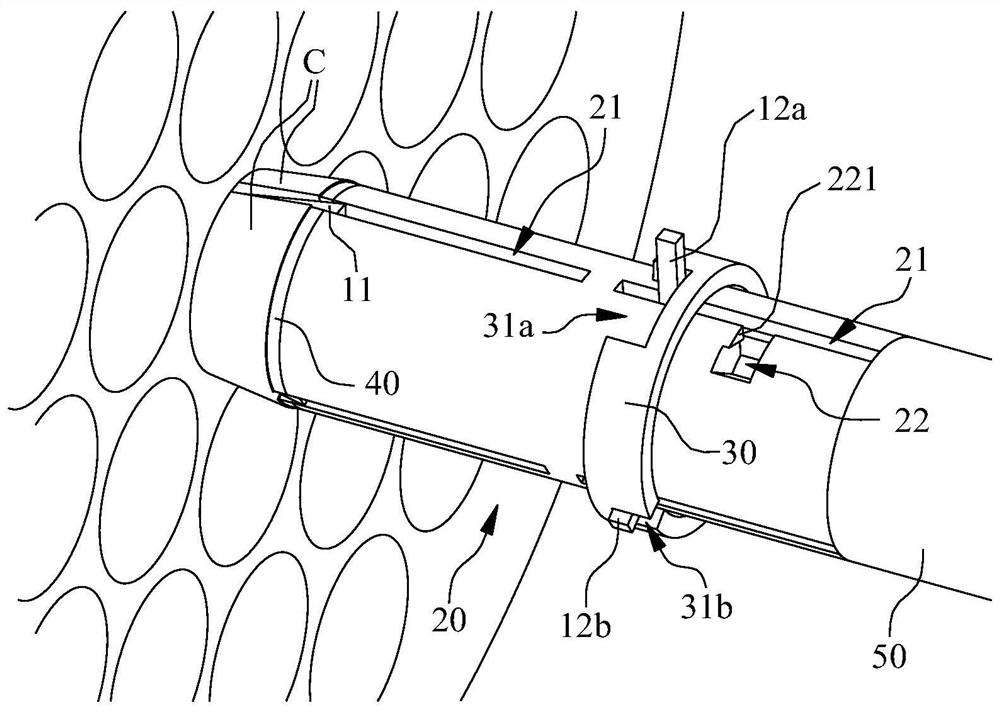

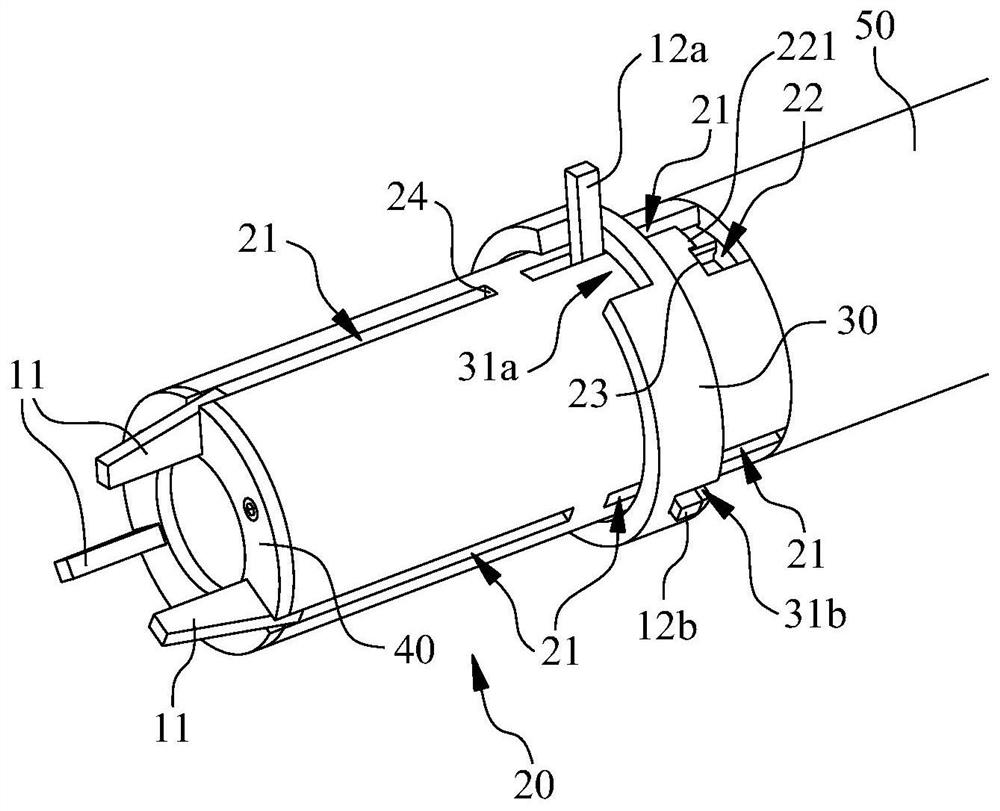

[0019] Below with the accompanying drawings, the description of the embodiments, specific embodiments of the present invention will be further described in detail.

[0020] For ease of description, the clip C is defined adjacent the front side or the front end, the rear side remote from the clip C or the rear end.

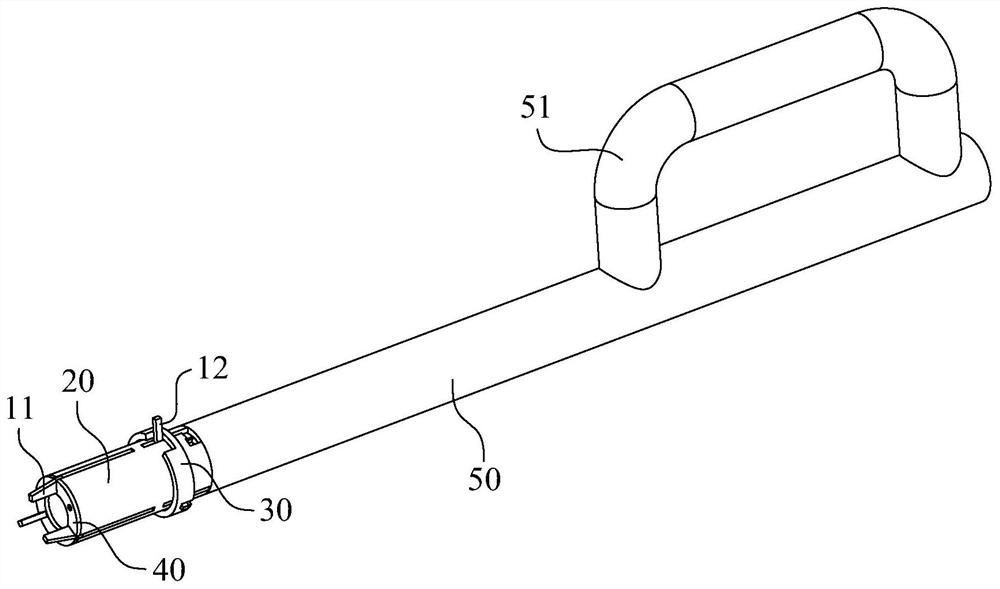

[0021] A clip-chip mounting accessories, comprising a circumferential symmetrically disposed spacer sheet 11 has a stem 20, stem 20 and the partition plate 11 constituting the stopper 20 with the displacement direction of the length of the stem, the partition plate 11 extending to the tube displacement between the end of the outer housing 20 and the retracted position of the overhang 20 is retracted to a position within the socket. like figure 2 , The partition plate 11 is in the cantilevered position, interposed between the clip C, to ensure a minimum spacing between two adjacent clips between C, avoiding excessive difference between the spacing large impact anchor cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com