Weaving reed with plurality of sheets

A technology for weaving reeds and thin sheets, which is applied in looms, textiles, textiles and papermaking, etc., can solve problems such as weaving reed deformation, and achieve the effect of improving linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

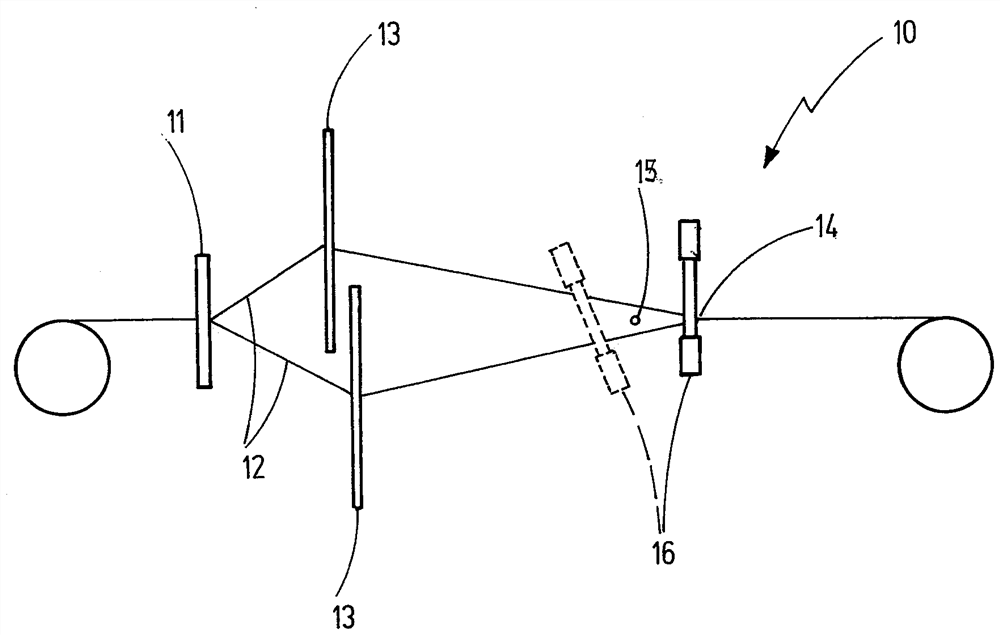

[0034] exist figure 1 The configuration of the loom 10 is schematically shown in . Starting from the pivoting backrest 11 , the warp threads 12 each run through a heald (not shown) in one of the plurality of heald frames 13 . The heald frames 13 can be moved vertically upwards or downwards to form a shed. On the warp thread exit side of the heald frame 13 the warp threads 12 run towards the selvedge 14 . The weft thread 15 can be introduced in front of the selvedge 14 into the shed opened by the heald frame 13 . The inserted weft thread 15 can be beaten up on the selvedge 14 by means of the reed 16 . For this purpose, the reed 16 can be moved and in particular pivoted in order to beat up on the selvedge 14 . exist figure 1The beating-up position of the reed 16 is shown by means of a solid line, while the return position of the reed 16 spaced apart from the selvedge 14 is shown by a dashed line.

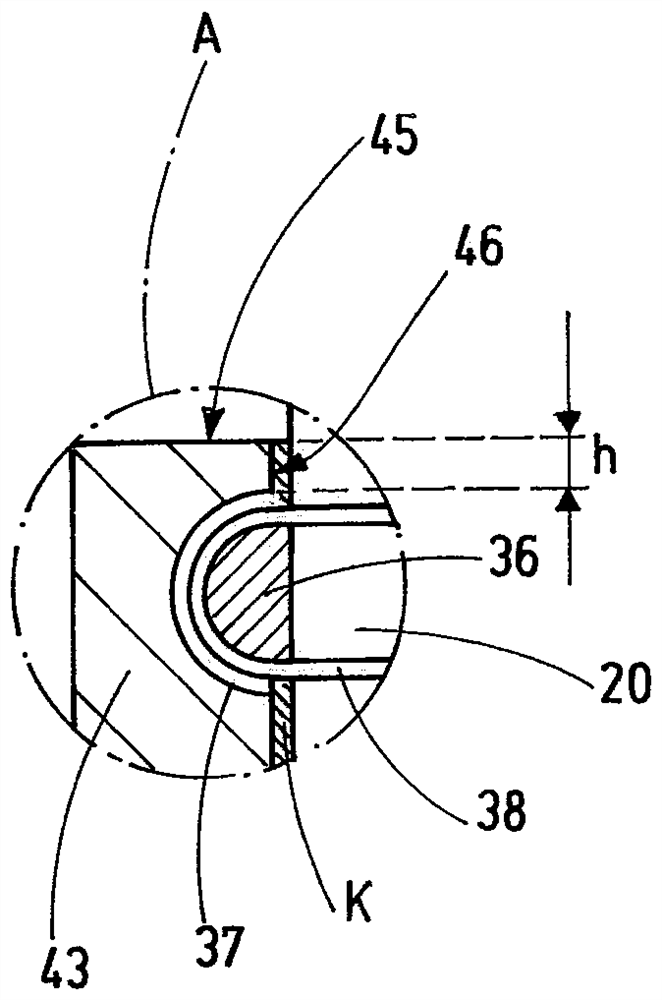

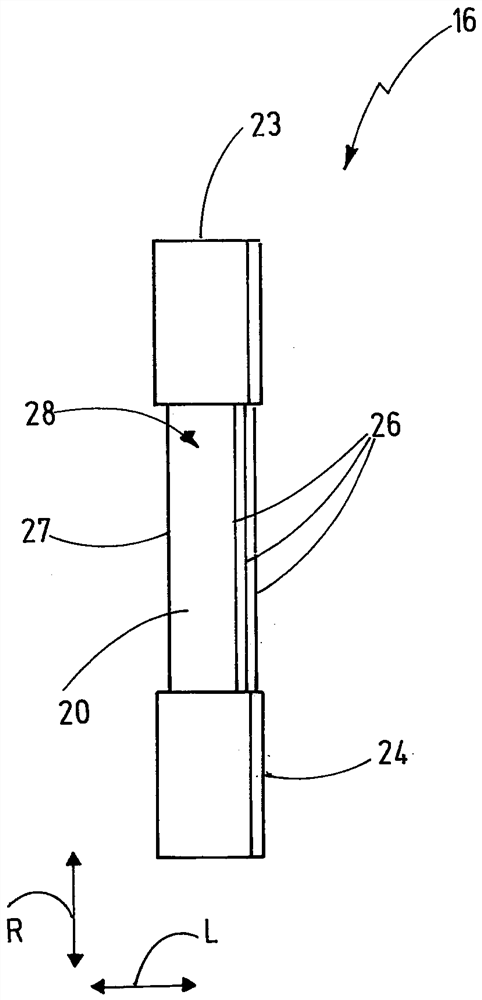

[0035] The reed 16 has a plurality of lamellae 20 . Each lamella 20 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com