Displacement frame girder bridge inspection vehicle

A frame and displacement technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of limited railway rail transit bridge lines, increased bridge construction costs, equipment flexibility restrictions, etc., to achieve distributed load distribution, safety protection design. The effect of humanization, increased convenience and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

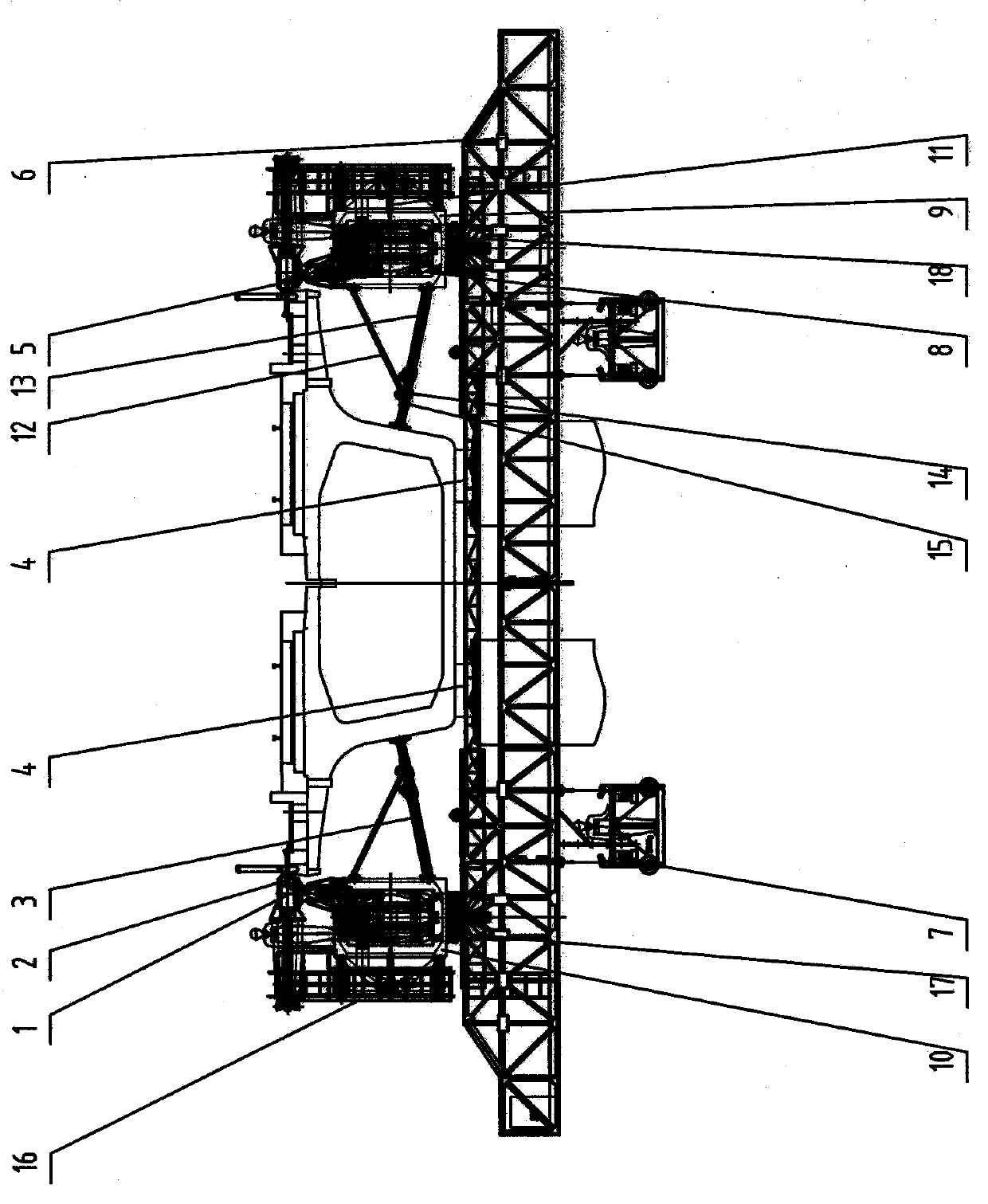

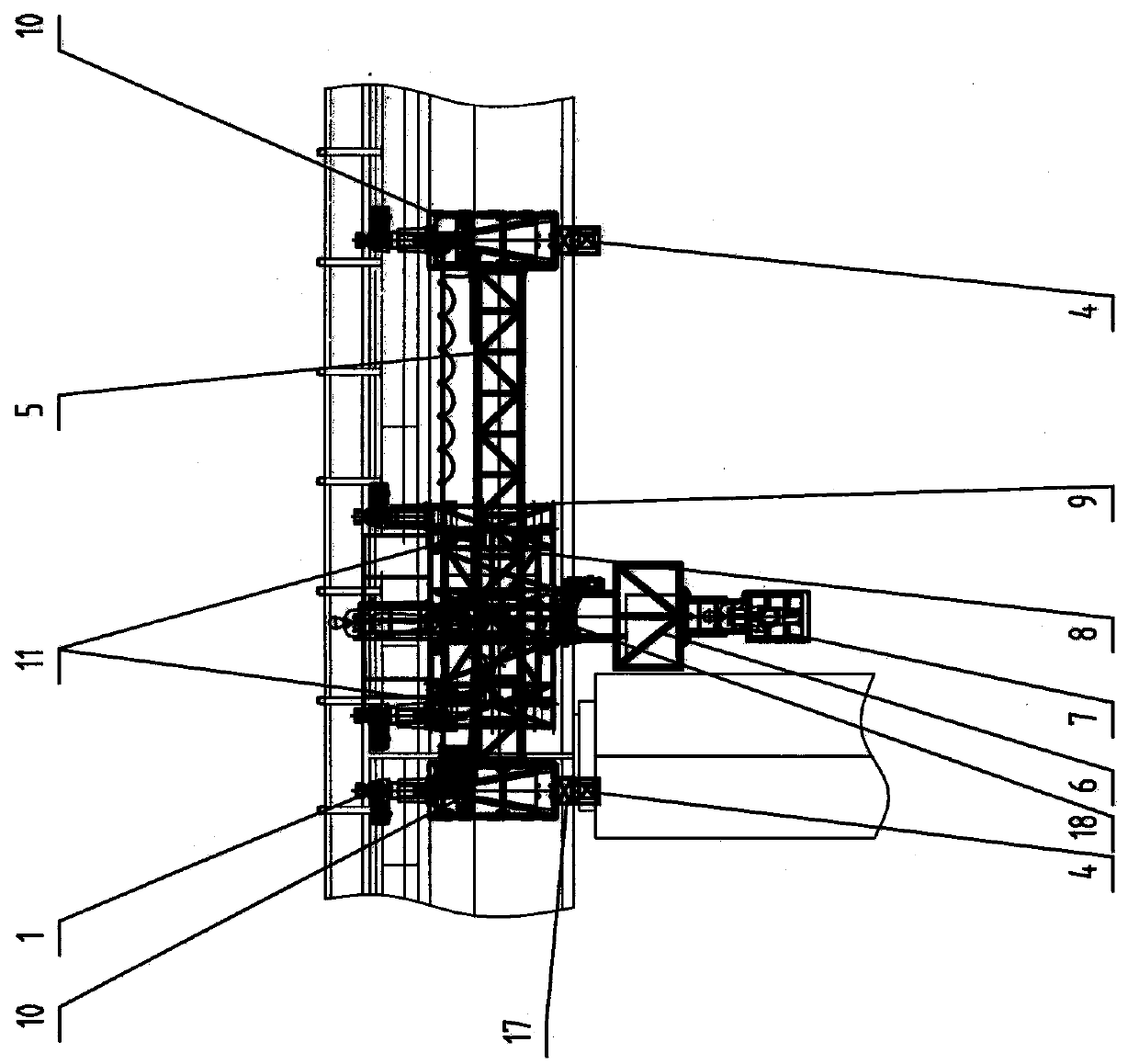

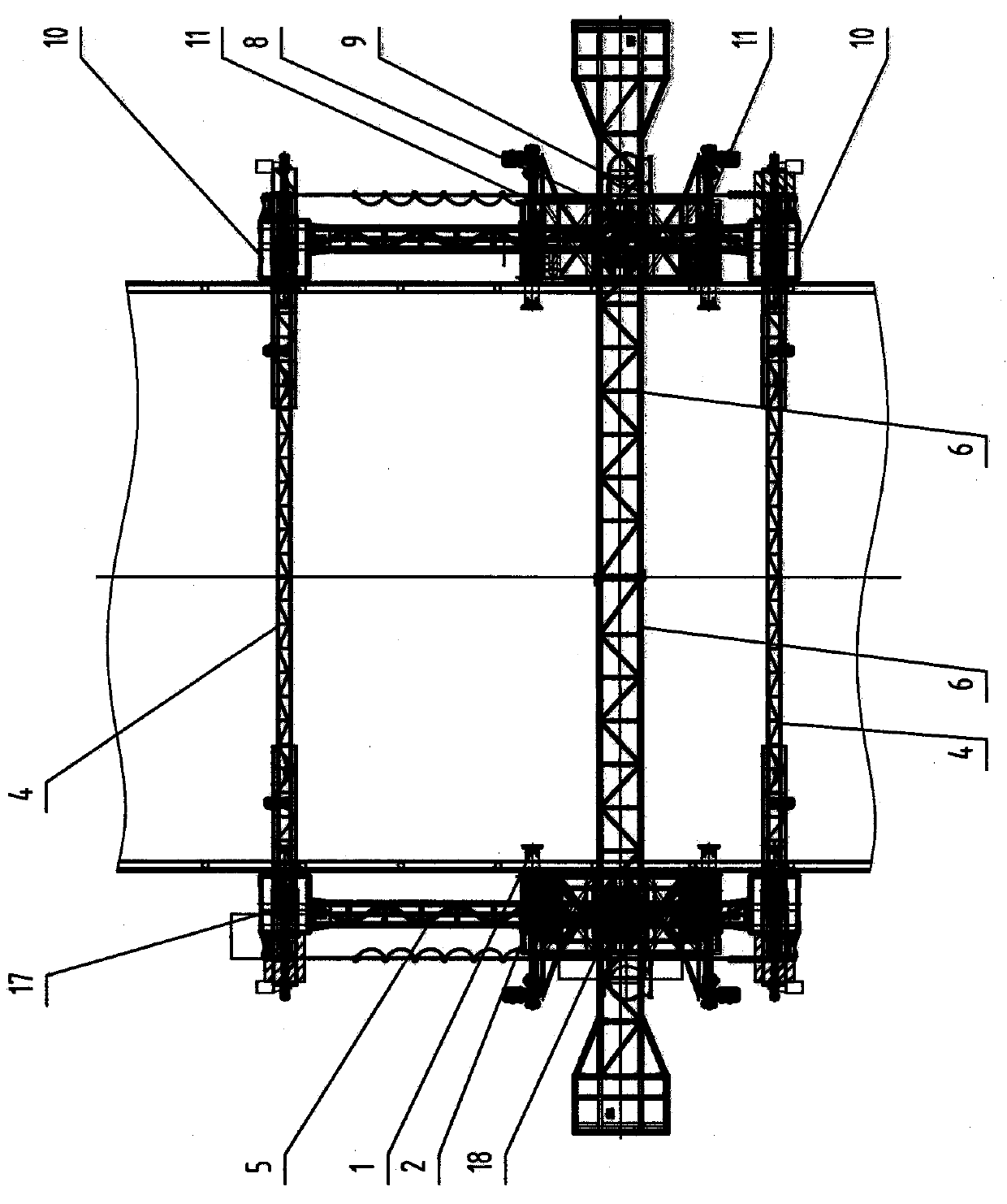

[0021] Such as figure 1 , figure 2 , image 3 As shown, the displacement frame beam type bridge inspection vehicle of the present invention includes: bridge deck self-locking hook palm 1, anti-collision roller 2, triangular outrigger 3, cross-link beam 4, guide beam 5, rotating platform 6, hanging basket 7, main Frame inner frame 8, main frame outer frame 9, fixed truss structure 10, electric push rod 11, fixed-length outrigger 12, telescopic leg 13, slider 14, limit device 15, steel ladder and guardrail 16, cross-link Beam lifting frame 17, rotating platform lifting frame 18, main frame outer frame 9 is connected with rotating platform 6, constitutes the passageway of detection and maintenance bridge.

[0022] Such as figure 1 As shown in the present invention, the displacement frame beam-type bridge inspection vehicle, the self-locking hook palm 1 of the bridge deck can be automatically fixed and locked or unlocked on the bridge edge of the bridge deck, and the self-lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com