Train shaft end generator

A technology for generators and shaft ends, which is applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of unstable transmission transmission mechanism, inconvenient maintenance in the later stage, etc., to improve stability, improve fixation firmness, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

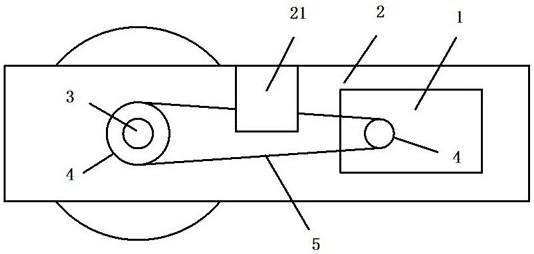

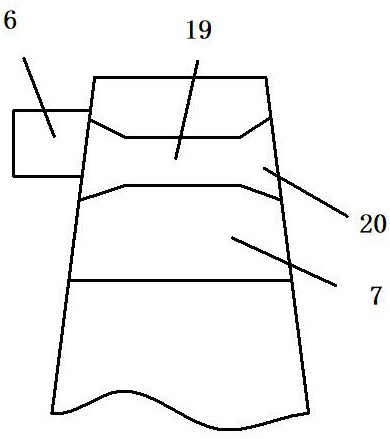

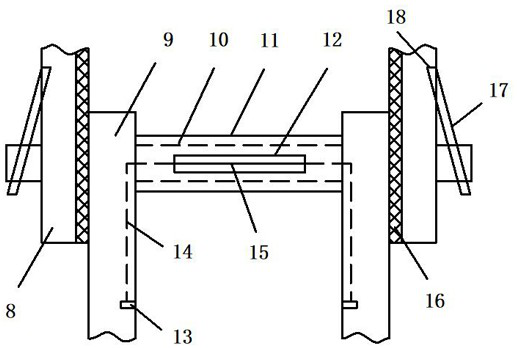

[0020] refer to Figure 1-7 , a specific embodiment of the present invention includes a generator assembly 1, the generator assembly 1 is fixed on the bogie 2, the wheel shaft 3 and the rotor shaft of the generator assembly 1 are respectively fixed with a gear 4, the two gears 4 Each tooth portion on the gear 4 is fixed with a boss 6 facing one end of the rotation direction, and the first rubber layer 7 is fixed on both sides of the tooth portion. The chain 5 includes an outer chain connected end to end in sequence. The plate 8 and the inner chain plate 9, the outer chain plate 8 and the inner chain plate 9 are connected by a pin shaft 10, the outer side of the pin shaft 10 is regulated by a shaft sleeve 11, and the shaft sleeve 11 is provided with a card slot 12, a card slot 12 Fitted with the boss 6, the inner side of the inner link plate 9 is provided with a slot 13, and the two ends of the elastic piece 14 are inserted into the two symmetrical slots 13, and the middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com