Cable buffer layer partial discharge testing device capable of controlling temperature and humidity

A partial discharge and testing device technology, applied in the field of high-voltage equipment, to achieve the effects of controllable defect types, controllable and accurate experimental temperature and humidity, and accurate and controllable contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

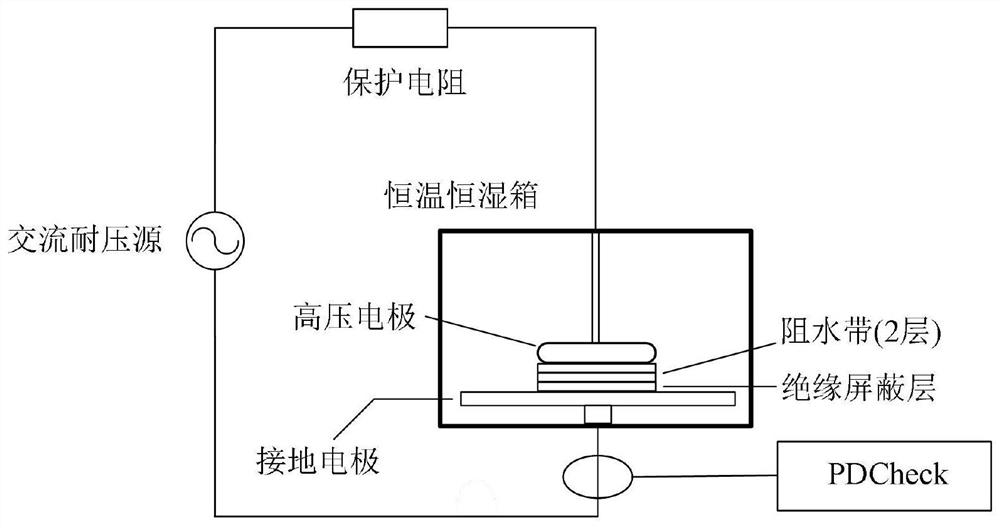

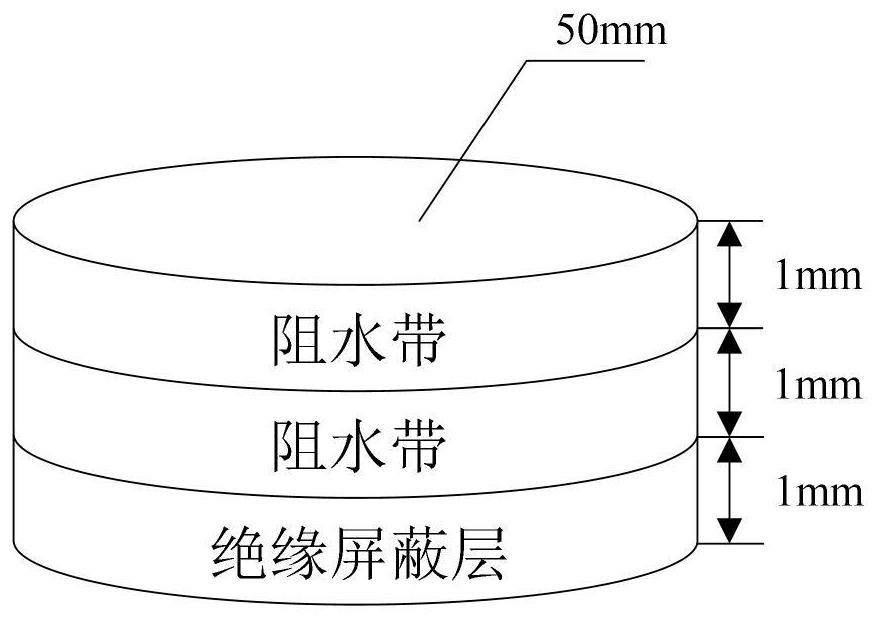

[0027] A partial discharge test device for cable buffer layer with controllable temperature and humidity, such as figure 1 As shown, including AC withstand voltage source, test electrode, constant temperature and humidity chamber and partial discharge collection device. The test electrode and the sample to be tested are installed in a constant temperature and humidity box to ensure that the temperature and humidity are constant during the test, and different temperature and humidity environments are generated by the constant temperature and humidity box for the partial discharge test of the cable buffer layer. The test electrode includes a high-voltage electrode and a ground electrode, the high-voltage electrode is connected to the high-voltage side of the AC withstand voltage source through a protective resistor, and the ground electrode is connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com