Pressure sensing module, touch control assembly, electronic equipment and touch control method

A technology of sensing modules and touch components, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems such as unsatisfactory requirements, achieve simple structure, convenient manufacture, and reduce overall volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

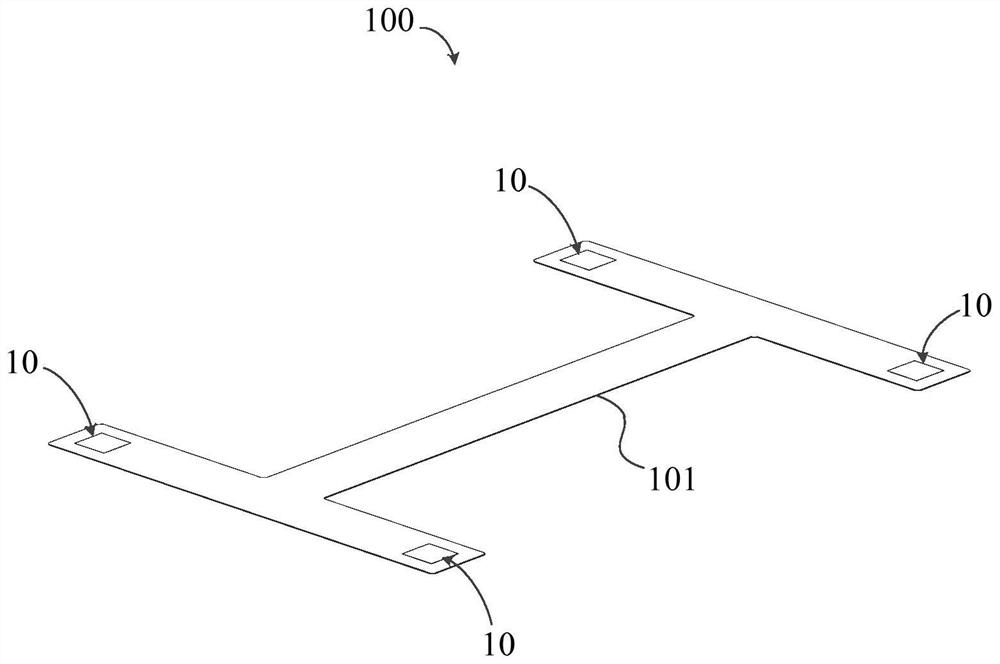

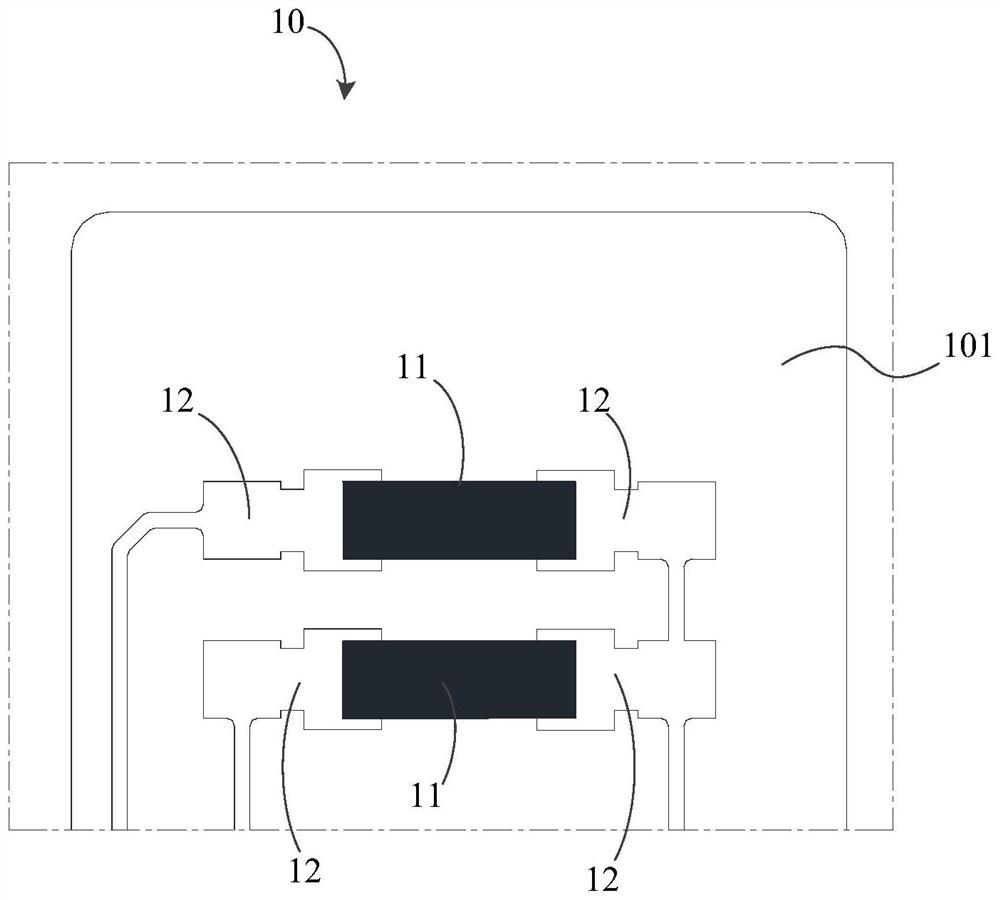

[0070] refer to Figure 1 to Figure 8 As shown, the present embodiment provides a pressure sensing module 100 . The pressure sensing module 100 includes: at least one set of pressure sensing structures 10, each set of pressure sensing structures 10 includes at least two piezoresistors 11, and the at least two piezoresistors 11 are connected in series to form a loop.

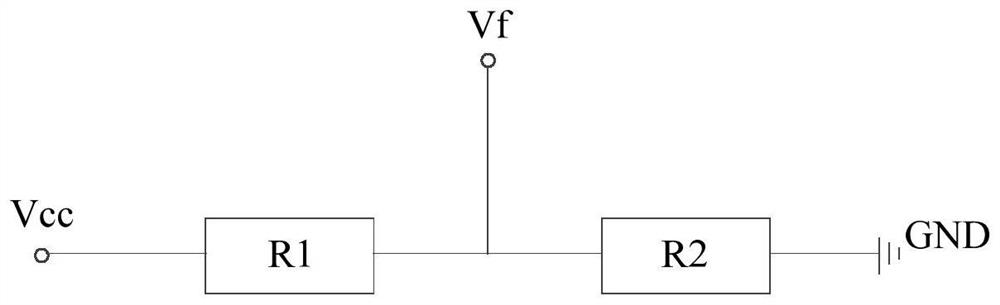

[0071] Wherein, the piezoresistor part 11 can be deformed under the action of pressing, so that the resistance value of the piezoresistor part 11 changes with the change of deformation, and then the voltage component on the piezoresistor part 11 changes; wherein, Different voltage component values are used to correspond to different control commands.

[0072] refer to figure 2 and image 3 As shown, the pressure sensing structure 10 includes two piezoresistor parts 11 as an example for description, wherein one piezoresistor part 11 (for example figure 2 located above the piezoresistor section 11, that is ...

Embodiment 2

[0101] refer to Figure 4 As shown, this embodiment provides a touch component 200 . The touch component 200 includes: a pressure sensing module 100 and a control board 20 .

[0102] The structure of the pressure sensing module 100 in this embodiment is the same as that of the pressure sensing module 100 provided in the first embodiment, and can bring the same or similar technical effects, which will not be repeated here, and details can be referred to in the first embodiment description of.

[0103] combine Figure 1 to Figure 8 As shown, the pressure sensing module 100 is electrically connected to the control board 20, and the control board 20 is used to generate control commands according to the change value of the voltage component when one of the piezoresistor parts 11 in the pressure sensing structure 10 is pressed.

[0104] It can be understood that when the pressure sensing module 100 includes at least two groups of pressure sensing structures 10 , the at least two gr...

Embodiment 3

[0109] refer to Figure 1 to Figure 8 As shown, this embodiment provides an electronic device 300 . The electronic device 300 includes: a touch panel 30 and a touch component 200 .

[0110] The structure of the touch control component in this embodiment is the same as that of the touch control component 200 provided in the second embodiment, and can bring about the same or similar technical effects, which will not be repeated here.

[0111] which, combined with Figure 5 , Image 6 as well as Figure 7 As shown, the pressure sensing module 100 is specifically disposed inside the touch panel 30 .

[0112] By disposing the pressure sensing module 100 inside the touch panel 30, the pressure sensing module 100 includes at least one set of pressure sensing structures 10, the pressure sensing structure 10 includes at least two piezoresistor parts 11, and the at least two The piezoresistor parts 11 are connected in series to form a loop. When in use, the finger presses the touch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com