Pastry surface layer nut spraying equipment for food making

A technology for nuts and equipment, applied in the field of nut spraying equipment on the surface of cakes for food production, can solve the problems of uncontrollable amount, complicated process, difference in taste, etc., and achieve the effect of enhancing overall aesthetics, simplifying work procedures, and satisfying taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

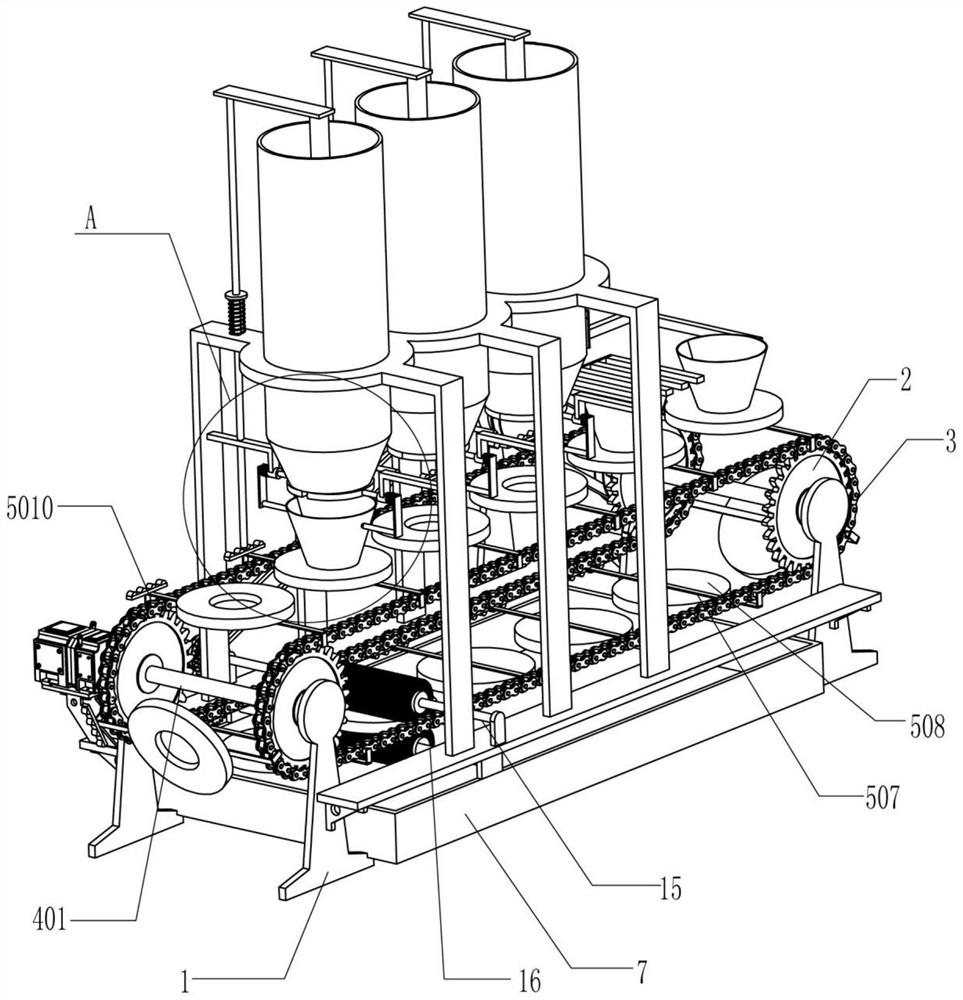

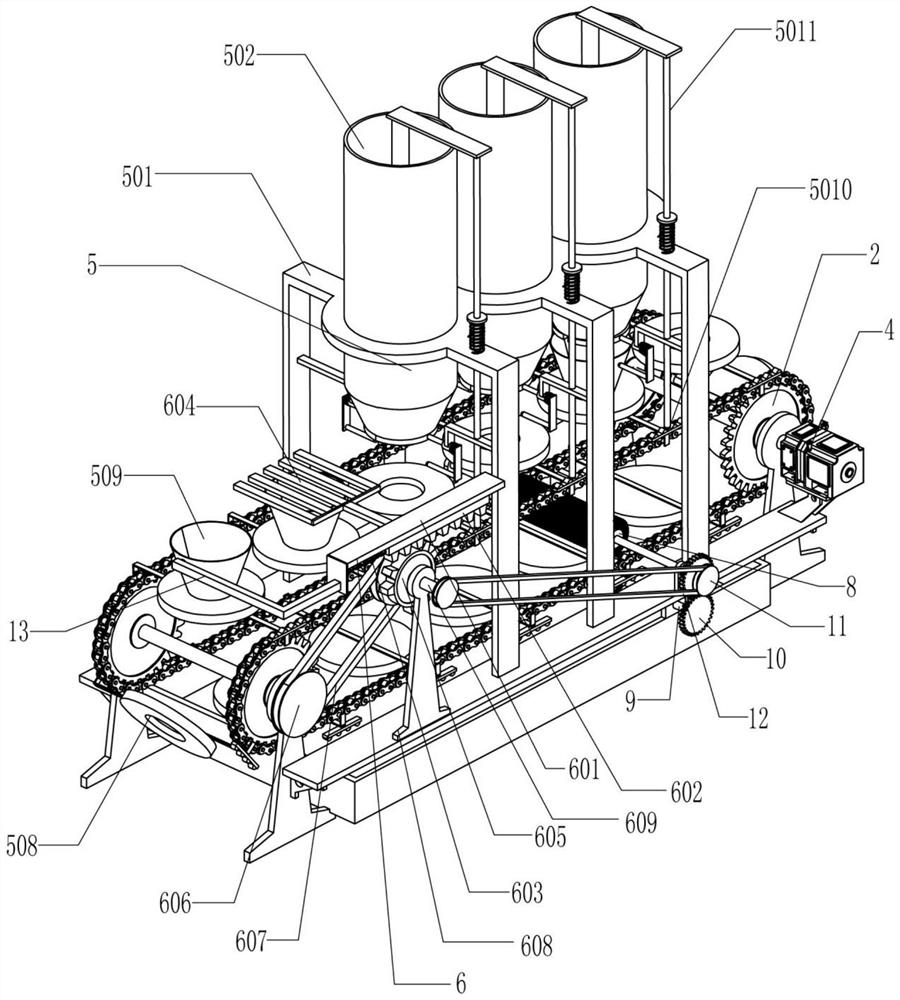

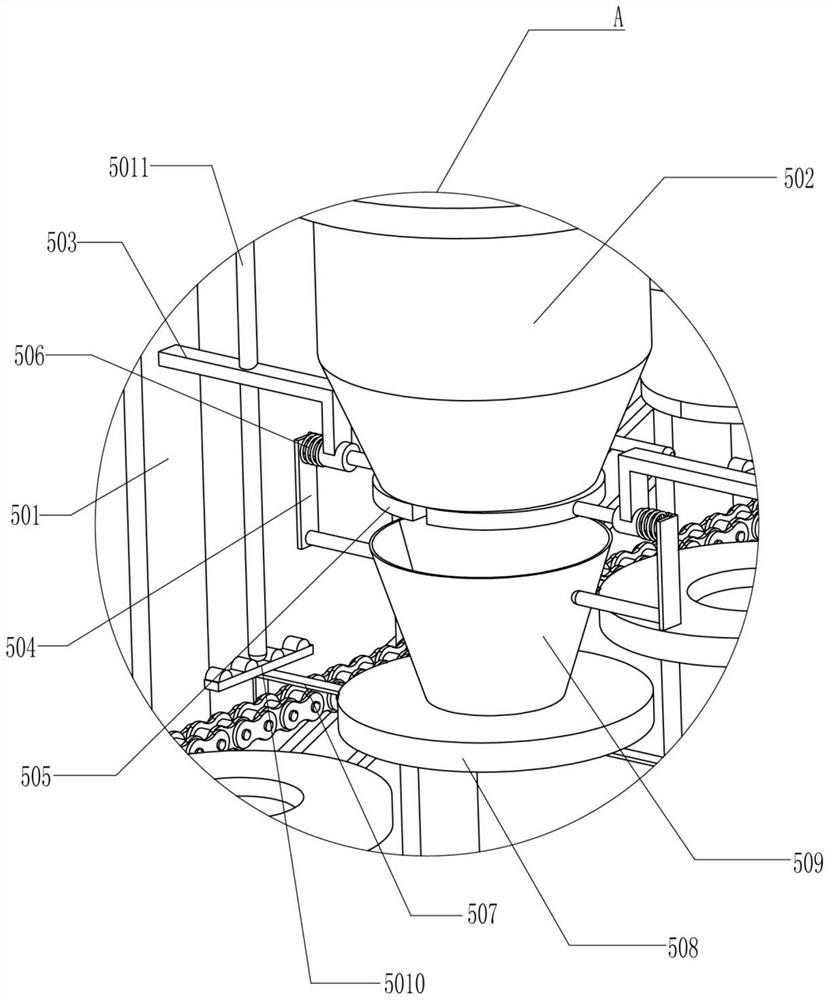

[0020] A kind of equipment for spraying nuts on the pastry surface layer for food production, such as Figure 1-5 As shown, it includes a base 1, a sprocket 2, a chain 3, a servo motor 4, a first rotating shaft 401, a nut spraying device 5 in batches, a nut surface scraping device 6 and a receiving frame 7. Two first rotating shafts 401 are installed through bearing rotation and pass through the base 1. The two first rotating shafts 401 are respectively located at the left and right ends of the base 1. Two first rotating shafts 401 are installed on the two first rotating shafts 401. Sprocket 2, chain 3 is respectively connected between two groups of said sprocket 2, said servo motor 4 is installed on the rear end of the left part of base 1 and the output shaft of servo motor 4 is connected with one of the first rotating shaft 401, so The nut spraying equipment 5 in batches is arranged on the base 1, and the function of the nut spraying equipment 5 in batches is to spray a vari...

Embodiment 2

[0025] On the basis of Embodiment 1, such as figure 2 As shown, the nut surface scraping device 6 for scraping a variety of nuts includes a guide rail 601, a rack 602, a third compression spring 603, a scraper 604, a sector gear 605, and a first pulley 606 , the first flat belt 607, the bearing seat 608 and the second rotating shaft 609, the guide rail 601 is fixedly installed on the right side of one of the fixed frames 501 and located above the chain 3, and the rack 602 is slidably installed on the guide rail 601 Above, a third compression spring 603 is installed between the right end of the rack 602 and the left side of the guide rail 601, the scraper 604 is fixedly installed on the rack 602 and is located above the cone 509, the scraper The plate 604 is used to scrape the nuts piled up on the pastry so that the upper surface of the whole pastry is covered with the nuts. The bearing seat 608 is fixedly installed on the base 1 and is located on the right side of one of the ...

Embodiment 3

[0028] On the basis of Example 2, such as figure 2 As shown, it also includes a first rolling brush 8, a second rolling brush 9, a driving gear 10, a second pulley 11, a second flat belt 12, a first rotating shaft 15 and a second rotating shaft 16. On the base 1 A first rotating shaft 15 and a second rotating shaft 16 are installed in rotation, and the first rotating shaft 15 is above the second rotating shaft 16, the first rolling brush 8 is installed on the first rotating shaft 15, and the first rotating shaft 15 Two rolling brushes 9 are installed on the second rotating shaft 16, and the first rolling brush 8 and the second rolling brush 9 are all used to drop the nut grain brush sticking to the opening limit disc 508 into the receiving frame 7 Collect, drive gear 10 is installed on the first rotating shaft 15 and the front end of the second rotating shaft 16, two described driving gears 10 mesh with each other, the front end of the first rotating shaft 15 and the second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com