Tea leaf stir-frying de-enzyming machine

A greening machine and tea technology, which is applied in the fields of tea greening and tea processing, can solve the problems of unadjustable, uncontrollable factors, and low efficiency of tea greening, and achieve the effects of reducing labor intensity, improving the efficiency of greening, and better quality of greening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

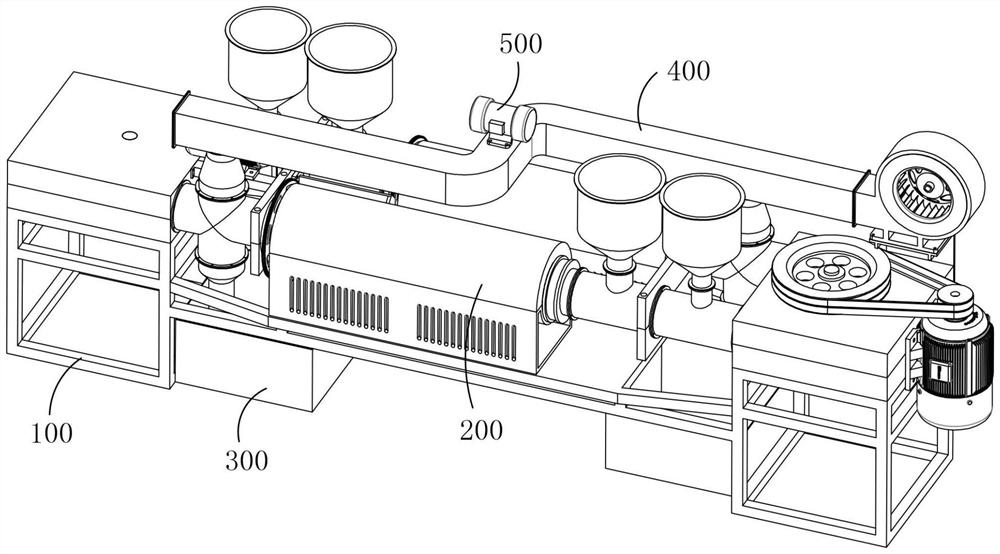

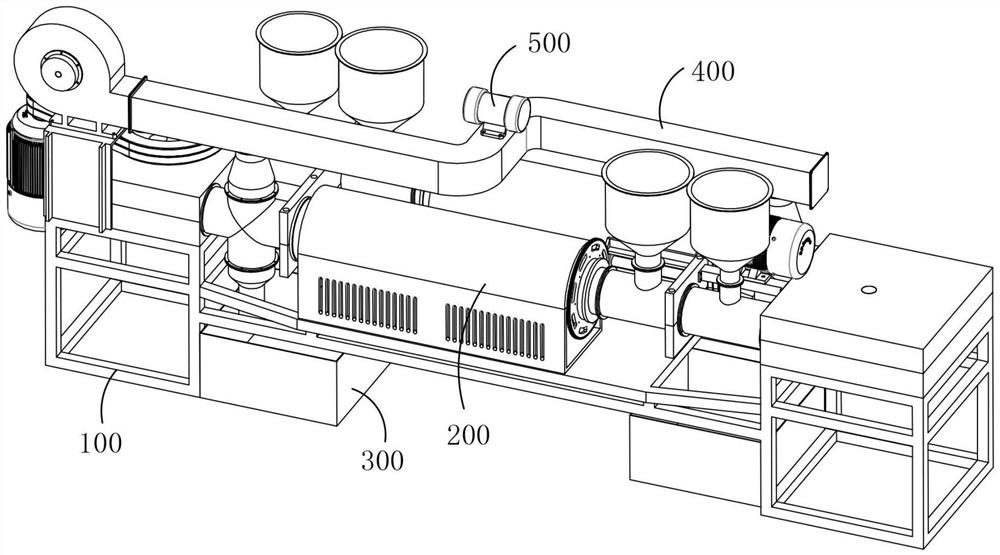

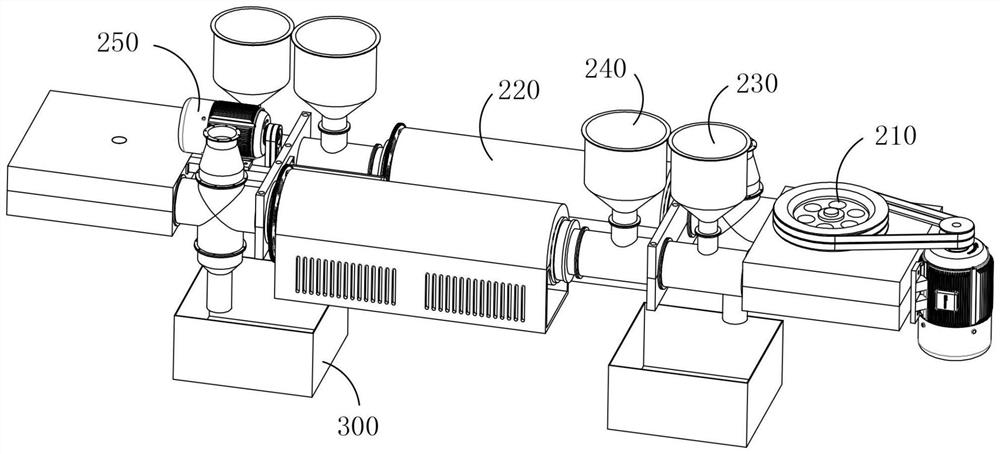

[0077] Tea stir frying machine, which includes the main frame body 100 installed on the ground, the main frame body 100 is equipped with a heating and fixing device 200 and a storage box 300, the heating and fixing device 200 is used to receive the picked tea leaves and heat and fix the tea leaves For processing, the storage box 300 is used for receiving and temporarily storing the tea leaves that have been greened by the heating and greening device 200 .

[0078] The heating and fixing device 200 includes a pipe chain transportation mechanism 210, a heating and fixing mechanism 220, a feeding funnel 1 230, and a feeding funnel 2 240. The pipe chain transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com