Airing and fixation device capable of simulating sun illumination

A technology of fixing greening device and simulating the sun, applied in food processing, food science and other directions, can solve the problems of affecting the production efficiency of spices, time-consuming and labor-intensive, weather restrictions, etc., to achieve high market application value, improve greening efficiency, and ensure manufacturing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

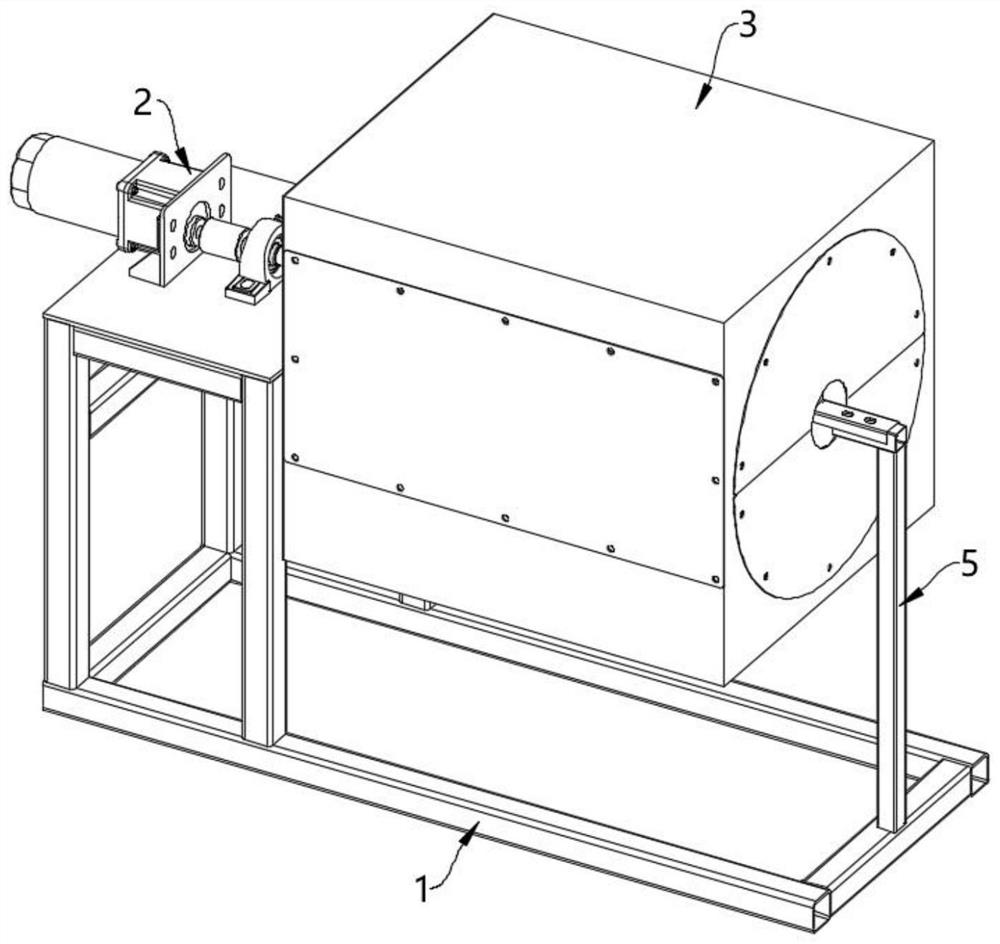

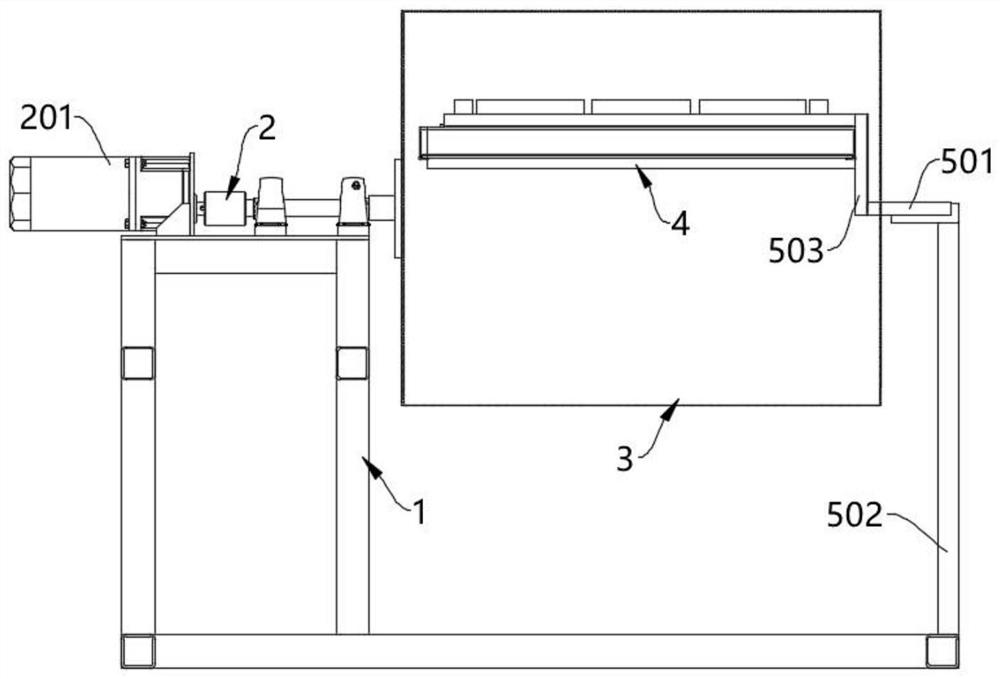

[0024] see Figure 1-2 As shown, the present invention is a drying and finishing device for simulating sunlight, including a conventional support frame 1 in the field; a power assembly 2 is installed on the support frame 1; The output end of the processing box 3 is connected with one side wall of the processing box 3; the power assembly 2 is used to drive the processing box 3 to rotate; During use, by pouring the spice raw material into the processing box 3, using the power assembly 2 to drive the processing box 3 to rotate, and using the light source 4 to simulate the effect of sunlight on the spice raw material, thereby not only effectively improving the speed of the spice raw material. , and can achieve full and uniform drying of all surfaces of the spice raw materials, and also greatly shorten the drying time of the spice raw materials and reduce the labor intensity of workers, ensuring the manufacturing efficiency of the spices.

specific Embodiment 2

[0025] On the basis of the specific embodiment 1, the differences of this embodiment are:

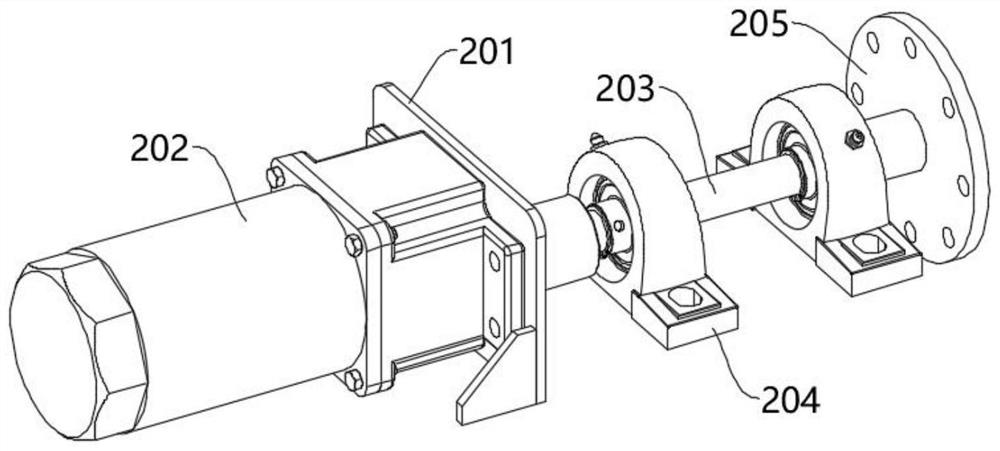

[0026] like image 3 As shown, the power assembly 2 includes a mounting plate 201 vertically fixed on the support frame 1; one side of the mounting plate 201 is vertically fixed with a drive motor 202; the output shaft of the drive motor 202 is coaxially connected through a conventional coupling in the field There is a transmission shaft 203; a pair of conventional rolling bearings in the field are arranged side by side on the transmission shaft 203; the rolling bearing is installed on a bearing seat 204; The bearing end cover 205 is bolted to one side wall of the processing box 3 . During use, the driving motor 202 transmits the power to the bearing end cover 205 through the transmission shaft 203, so that the processing box 3 rotates with the transmission shaft 203, thereby realizing the turning of the spice raw materials in the processing box 3, and effectively ensuring the spice ra...

specific Embodiment 3

[0027] On the basis of the second specific embodiment, the differences of this embodiment are:

[0028] like figure 2 As shown, the processing box 3 includes a box body 301; the other side wall of the box body 301 is provided with a feeding port; the feeding port is screwed with a sealing plate 302 in a circular structure; the sealing plate 302 has a pair of semicircular The supporting plate of the structure is formed; an outer wall of the box body 301 has a first open structure; the first open structure is bolted with a matching transparent baffle 304 . When in use, the spice raw materials are put into the box body 301 through the feeding port, and then the sealing plate 302 is installed at the feeding port. When the box body 301 is turned over, the transparent baffle 304 can be used to observe the spice raw materials in the box body 301. drying condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com