Self-locking type sand core standard core tool and application method thereof

A self-locking, standard core technology, applied in the direction of cores, manufacturing tools, metal processing equipment, etc., can solve the problems of sand inclusions, fire escape, and easy fire choking, etc., to reduce operating steps, reduce production costs, reduce The effect of casting size out of tolerance and choking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the technical solution of the present invention more clearly, the present invention will be further described in detail below in conjunction with specific examples. Please note that the embodiments described below are exemplary only for explaining the present invention, and should not be construed as limiting the present invention.

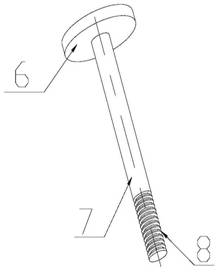

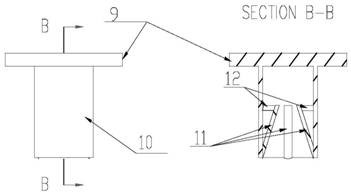

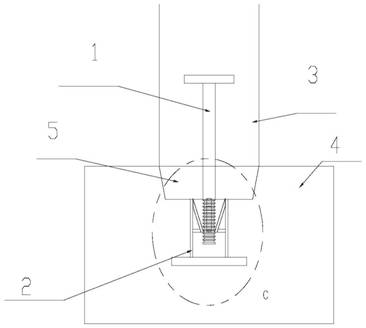

[0032] A self-locking sand core standard tooling, such as figure 1 and figure 2 , including the core rod section 1 embedded in the sand core and the corresponding core cap section 2 embedded in the sand mold.

[0033] Both ends of the core rod section 1 are provided with external threads, the middle part is a polished rod, and the core rod section 1 is made of a solid steel rod.

[0034] Further, the core rod section 1 is composed of a core rod hanging sand baffle plate 6 and a positioning rod 7 . One end of the locating rod 7 is fixedly connected to the plate surface of the core rod hanging sand baffle 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com