Ground leakage type water tight guiding and removing structure of refuse landfill and construction method thereof

A technology for landfills and landfills, which is applied in infrastructure engineering, sewage discharge, waterway systems, etc. It can solve the problems of high possibility of damage, poor pipeline resistance to external forces, etc., to ensure overall integrity and anti-seepage effect of effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

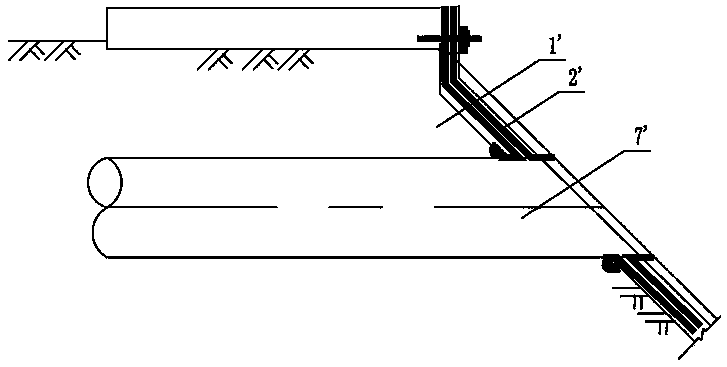

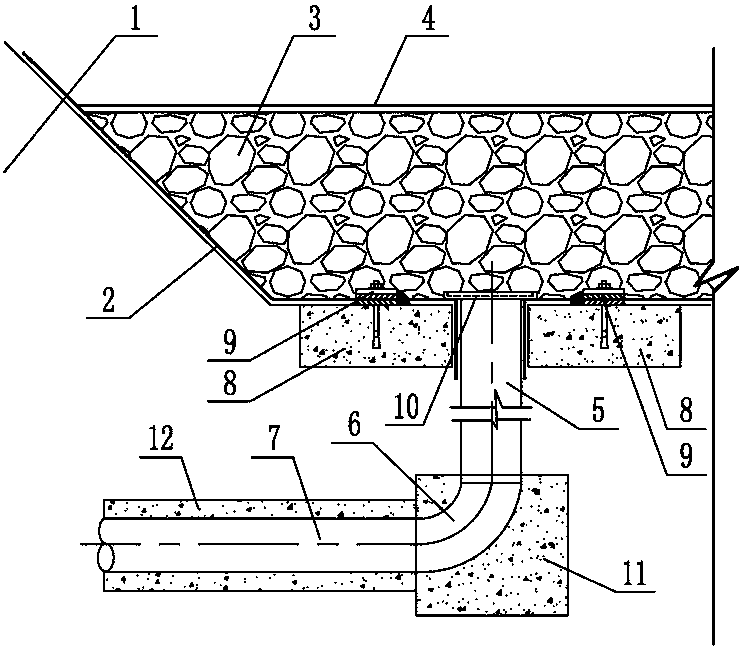

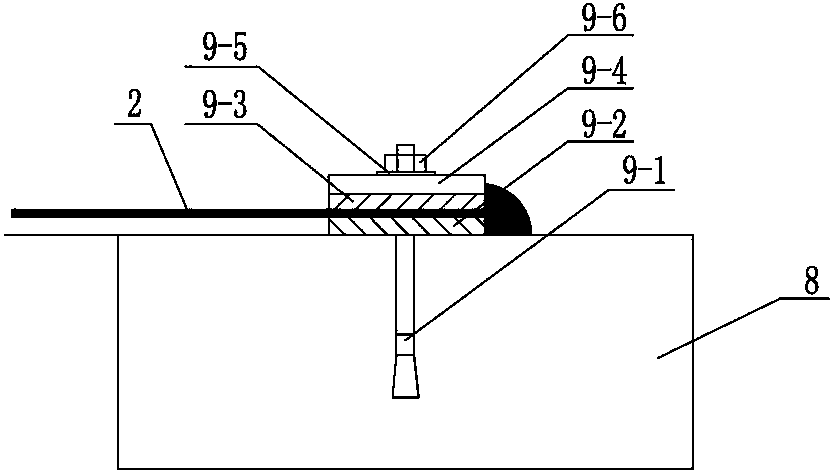

[0024] Such as figure 2 As shown, the present embodiment takes a valley-type landfill as an example. It forms a basin-shaped landfill reservoir area by building a garbage dam 1 at the entrance of the valley. HDPE anti-seepage film), on the top of the anti-seepage layer 2, the leachate drainage layer 3 and the filter geotextile 4 are laid in sequence from bottom to top, and the bottom of the landfill reservoir area is vertically arranged and the leachate drainage A short plastic pipe 5 connected to the layer 3. The upper end of the short plastic pipe has a flange and is welded to the anti-seepage layer 2 laid at the bottom of the reservoir area. The lower end is connected to the straight pipe 7 through the 90-degree elbow 6. The other end extends out of the garbage dam 1 and is connected to the external sewage treatment system; the number and elevation of the straight pipes 7 passing through the dam can be flexibly set according to the actual situation of the landfill, and wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com