Water-cooled flat wave reactor processing device and usage method thereof

A technology of smoothing reactors and processing devices, which is applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc., and can solve the problems of chip processing process influence, lack of adjustment structure, small application range, etc. , to facilitate processing, improve accuracy, and improve the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

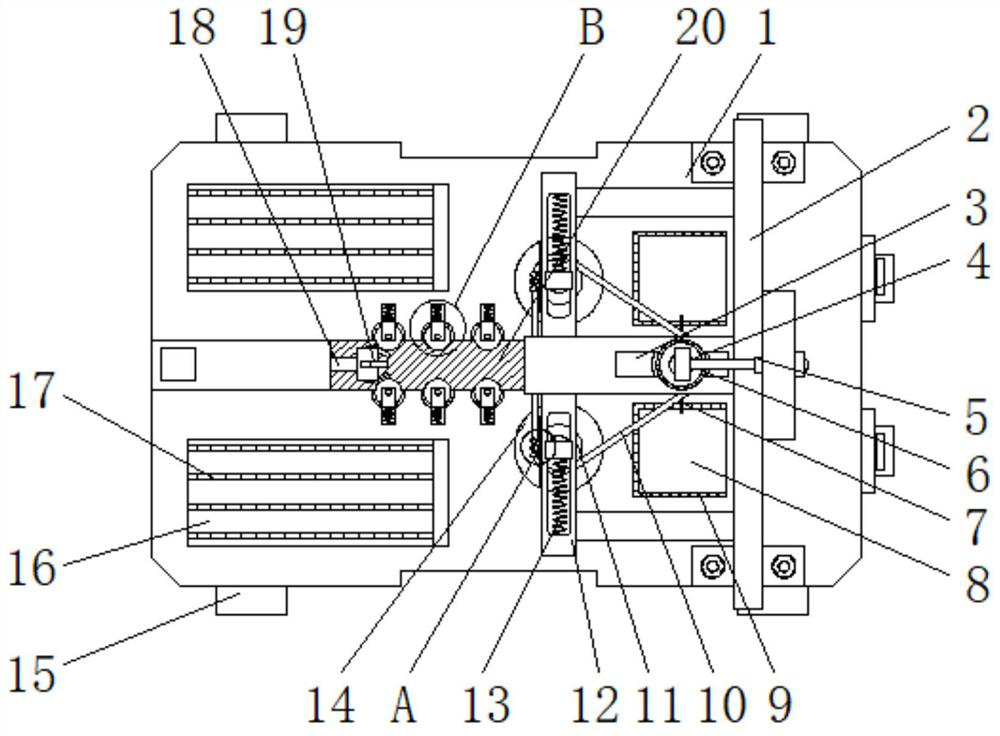

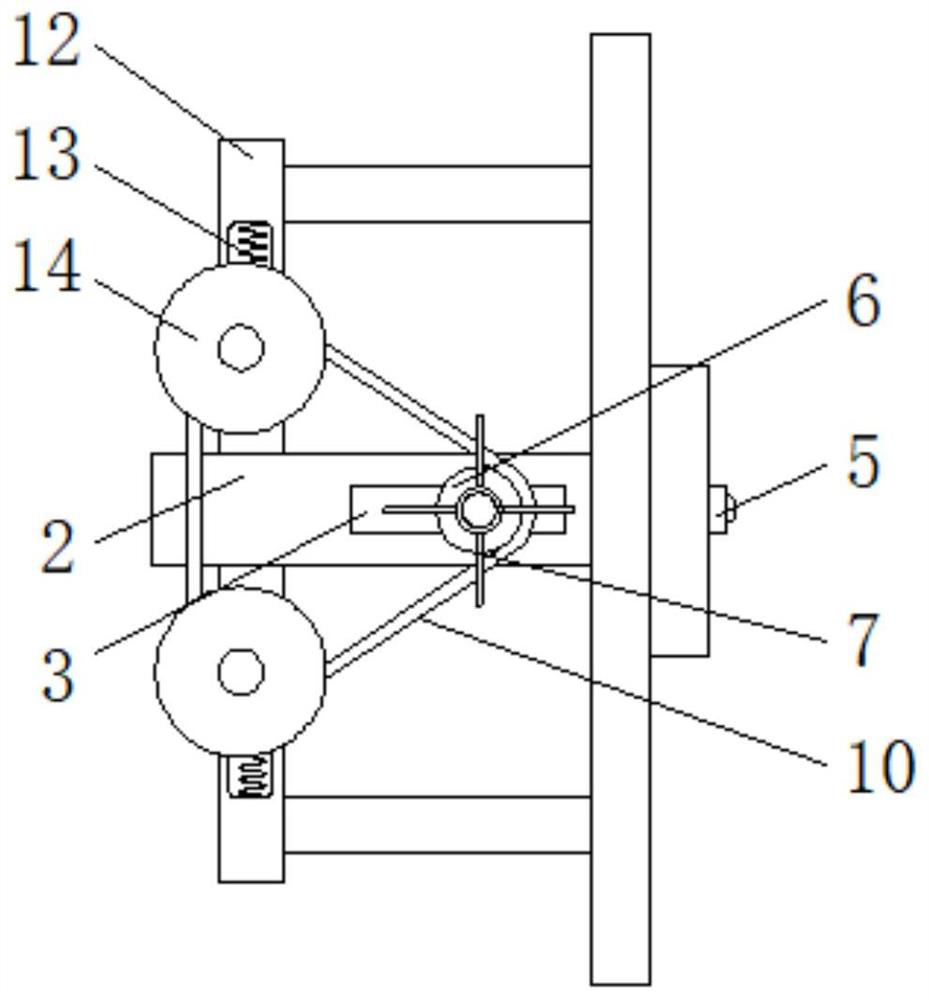

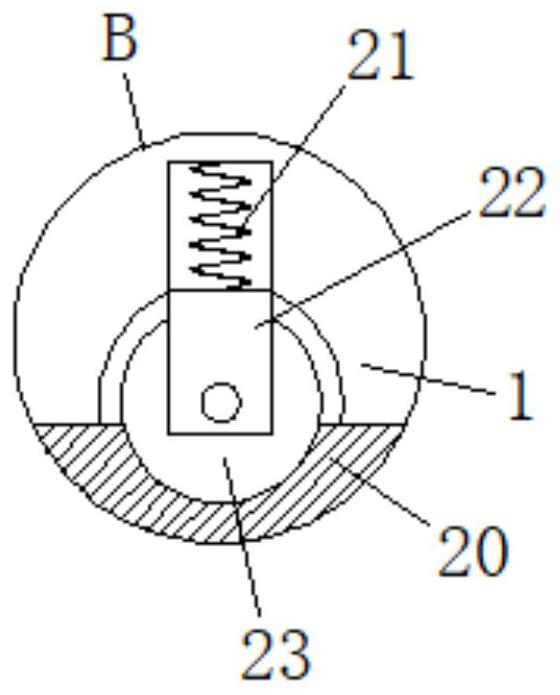

[0027] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0028] Such as Figure 1-4 As shown, the present invention provides a technical solution: a water-cooled smoothing reactor processing device, including a device base 1, the front of the device base 1 is fixedly connected with a fixing frame 2, and the upper and lower surfaces of the fixing frame 2 are fixedly connected with grooves plate 12, the front of the fixed frame 2 is provided with a first chute opening 3, and the back side of the fixed frame 2 is provided with a first turntable 6, and one end of the first turntable 6 is engaged in the first chute opening 3, and the fixed frame 2 A transmission mechanism 4 is arranged on the front, the output shaft of the transmission mechanism 4 is fixedly connected to one end of the front of the first turntable 6 , and the fan blade 7 is fixedly connected to one end of the back of the first turntable 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com