Sintered coal gangue brick loading and unloading manipulator

A technology of coal gangue and manipulator, which is applied in the field of manipulators, can solve problems such as the inability to adjust the clamping width, difficulty in clamping, and damage to gangue bricks, and achieve the effects of avoiding damage caused by collisions, easy manipulation, and accurate loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

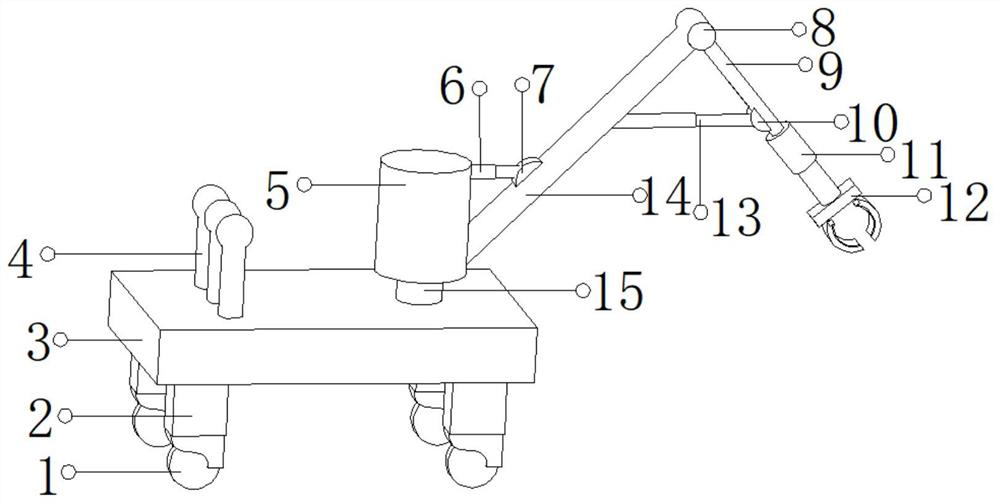

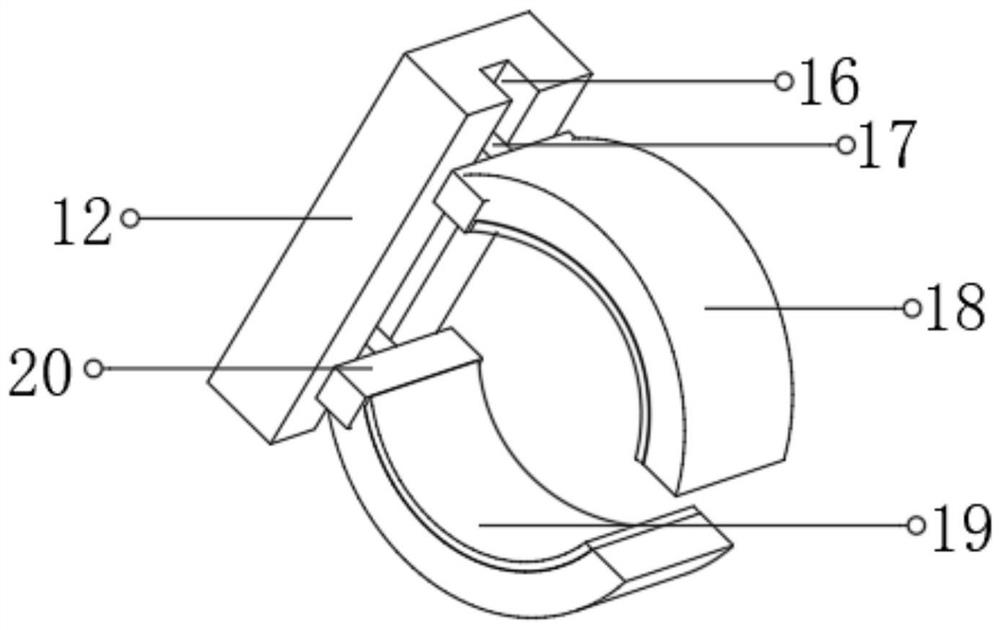

[0025] refer to Figure 1-2 , the manipulator for loading and unloading sintered gangue bricks, including a bottom plate 3, one end of the top outer wall of the bottom plate 3 is connected with a support column 15 by bolts, and the top outer wall of the support column 15 is rotatably connected with a fixed cylinder 5, and the position of the outer wall of one side of the fixed cylinder 5 near the top is connected by a hinge A first telescopic rod 6 is connected, and one end of the first telescopic rod 6 is connected with a first connection block 7 through a hinge, and a first oblique rod 14 is connected to the outer wall of one side of the fixed cylinder 5 near the bottom by bolts, and the first oblique rod 14 and the first connecting block 7 are connected by bolts, one end of the first slanting rod 14 is rotatably connected to the rotating shaft 8, and one end of the rotating shaft 8 is rotatably connected to the second slanting rod 9, and the outer wall on one side of the fir...

Embodiment 2

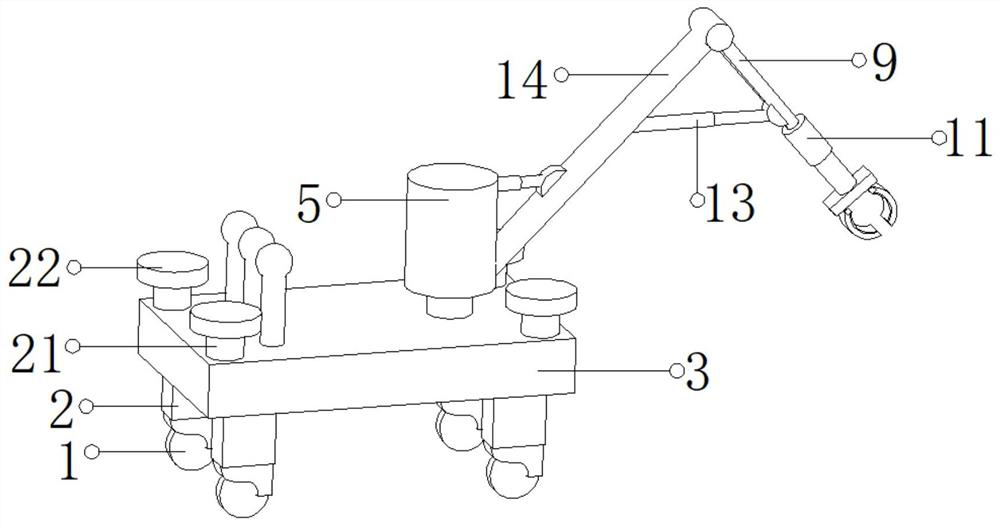

[0029] refer to image 3 , Sintered gangue brick loading and unloading manipulator, compared with embodiment 1, the four corners of the top outer wall of bottom plate 3 are connected with pillars 21 by bolts, and the top outer wall of pillar 21 is connected with anti-collision wheels 22 by bolts.

[0030] Working principle: When in use, first move the device to the place where sintered coal gangue bricks need to be loaded and unloaded, and then operate the device through multiple controllers 4, and control the first telescopic rod 6 and the second telescopic rod 13 to control the first The inclined bar 14 and the second inclined bar 9 enable the height and length of the device manipulator to be adjusted freely, and then move the slider 17 to slide on the electric slide rail 16, so that the distance between the two arc-shaped clamping plates 18 can be adjusted. Thereby, it is possible to clamp sintered gangue bricks of different specifications and sizes, which is convenient for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com