Efficiently-mounted injection mold mechanism

An injection mold, high-efficiency technology, applied in the field of efficient installation of injection mold mechanism, can solve the problems of affecting production efficiency, time-consuming, cumbersome installation and disassembly process, etc., to save installation time, low maintenance difficulty, save installation or disassembly time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

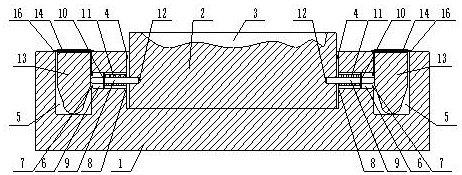

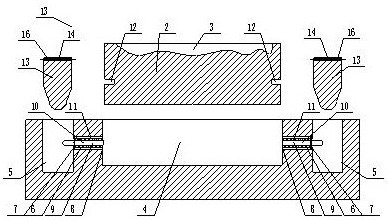

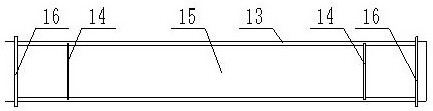

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 shown;

[0026] The invention of the present application lies in that two long grooves 5 are arranged on the upper surface of the mounting plate, and the two long grooves are symmetrical about the mounting grooves. Hole 6, several through holes are located between the long groove and the installation groove, one end of the through hole communicates with the inner cavity of the installation groove, and the other end communicates with the inner cavity of the long groove, and the port where the through hole communicates with the long groove Rib one 7 is fixedly installed, and rib two 8 is fixedly installed at the port where the through hole communicates with the installation groove, and a cylinder 9 is installed in the through hole, and one end of the cylinder passes through the rib one and stretches into the elongated groove, and the cylinder The other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com