A low-modulus high-damping rubber for seismic isolation of shield tunnels and its preparation and application

A seismic isolation and tunnel technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems that the durability of water-swellable materials cannot be guaranteed, and the performance of water-swellable rubber rings cannot be fully exerted, and it is easier to achieve construction quality Control and improve the effect of seismic isolation and the effect of reducing the maximum shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

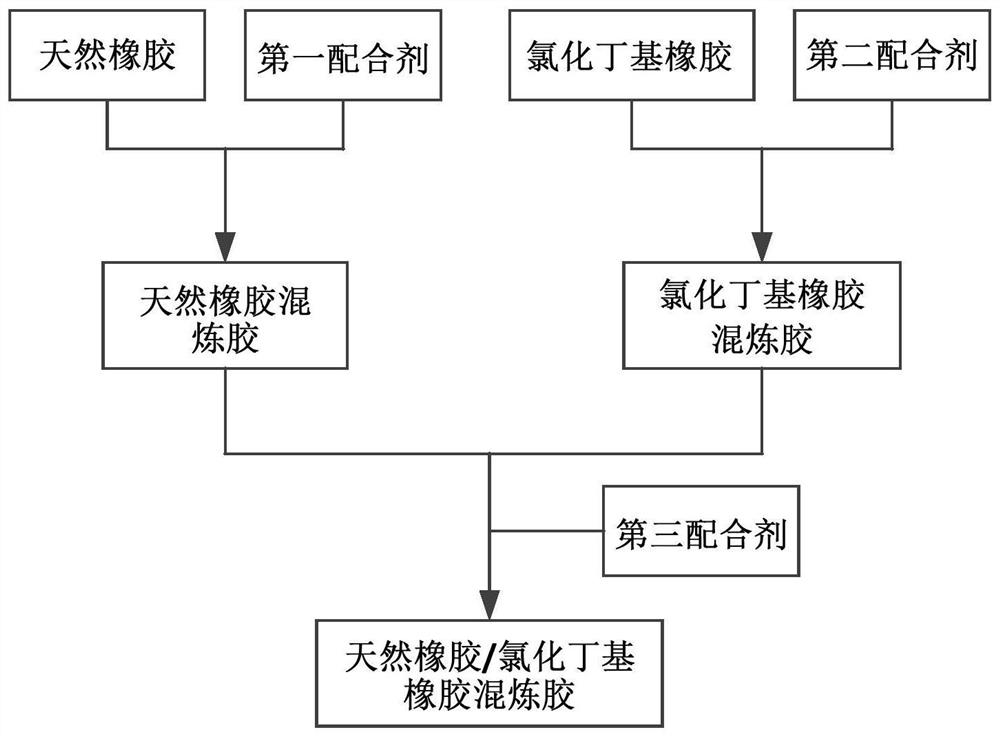

[0049] The present invention also provides a preparation method of the low-modulus high-damping rubber, comprising the steps of:

[0050] (1) Carry out masticating natural rubber raw rubber, control the masticating temperature to 40-50°C, add the first compounding agent, and knead to obtain natural rubber compound; the first compounding agent includes active zinc oxide, accelerator, One or more of carbon black and sulfur;

[0051] (2) Masticate the chlorinated butyl rubber raw rubber, control the plasticating temperature to 40-50°C, add the second compounding agent, and mix to obtain the chlorinated butyl rubber compound; the second compounding agent includes petroleum One or more of resin, activated zinc oxide, accelerator, carbon black and sulfur;

[0052] (3) After mixing the natural rubber compound and chlorinated butyl rubber compound, add a third compounding agent and mix uniformly to obtain a mixed compound; the third compounding agent includes carbon black, nano-scale...

Embodiment 1

[0072] Such as figure 1 As shown, in this embodiment, the natural rubber is first masticated 6 times on the open mill, and the temperature of the open mill is controlled to be 45°C, and 0.8wt% of active zinc oxide and 1.5wt% of the accelerator DZ(N,N -dicyclohexyl-2-benzothiazole sulfenamide), 25wt% carbon black, 1.5wt% sulfur, through 5 times of rubber tapping, triangular bagging, rolling, and uniform mixing to obtain natural rubber rubber compound.

[0073] The chlorinated butyl raw rubber was masticated on the open mill for 6 times, the temperature of the open mill was controlled at 45°C, and 15wt% petroleum resin, 0.8wt% active zinc oxide, and 1.5wt% accelerator DZ(N,N-di Cyclohexyl-2-benzothiazole sulfenamide), 25 wt% carbon black, 1.5 wt% sulfur. After 5 times of rubber tapping, triangular bagging, rolling, and uniform mixing, the chlorinated butyl rubber compound was obtained.

[0074] Mix natural rubber compound and chlorinated butyl rubber 1:1. Add 1.5wt% anti-agin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com