Eddy current three-dimensional damping device

A vibration damping device and eddy current technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, erection/assembly of bridges, etc., can solve the problems of complex vibration, achieve the effect of prolonging service life, avoiding difficult assembly and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

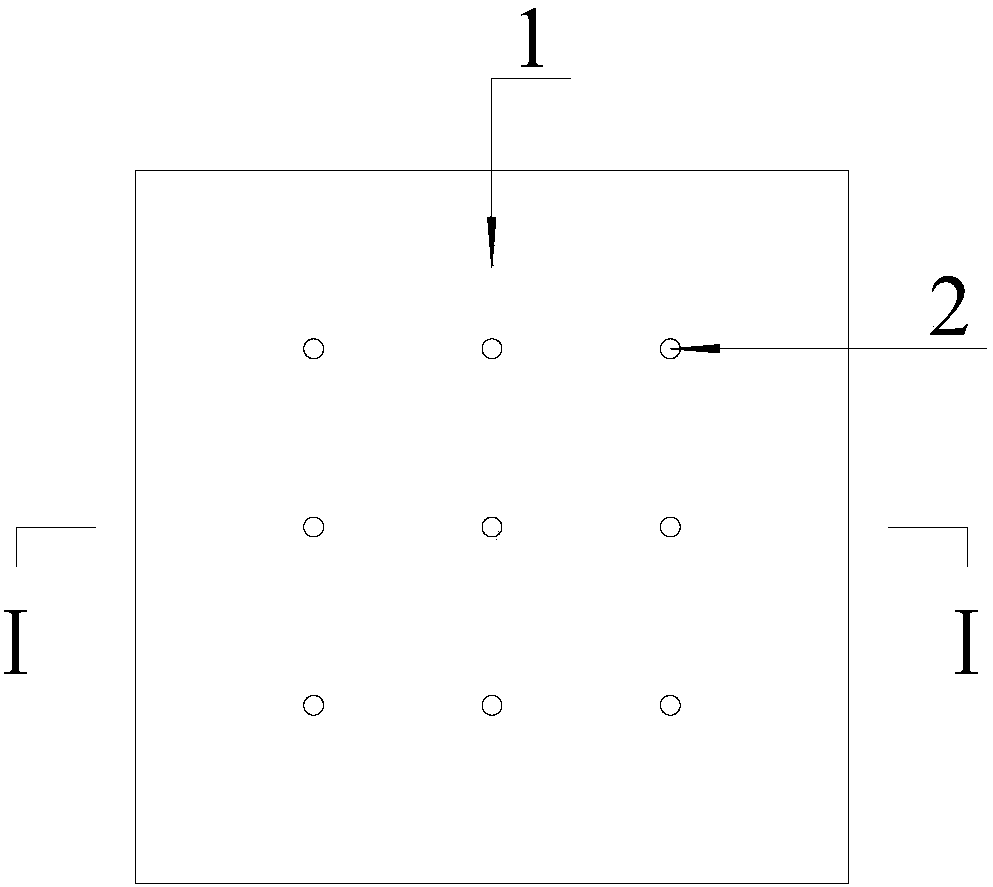

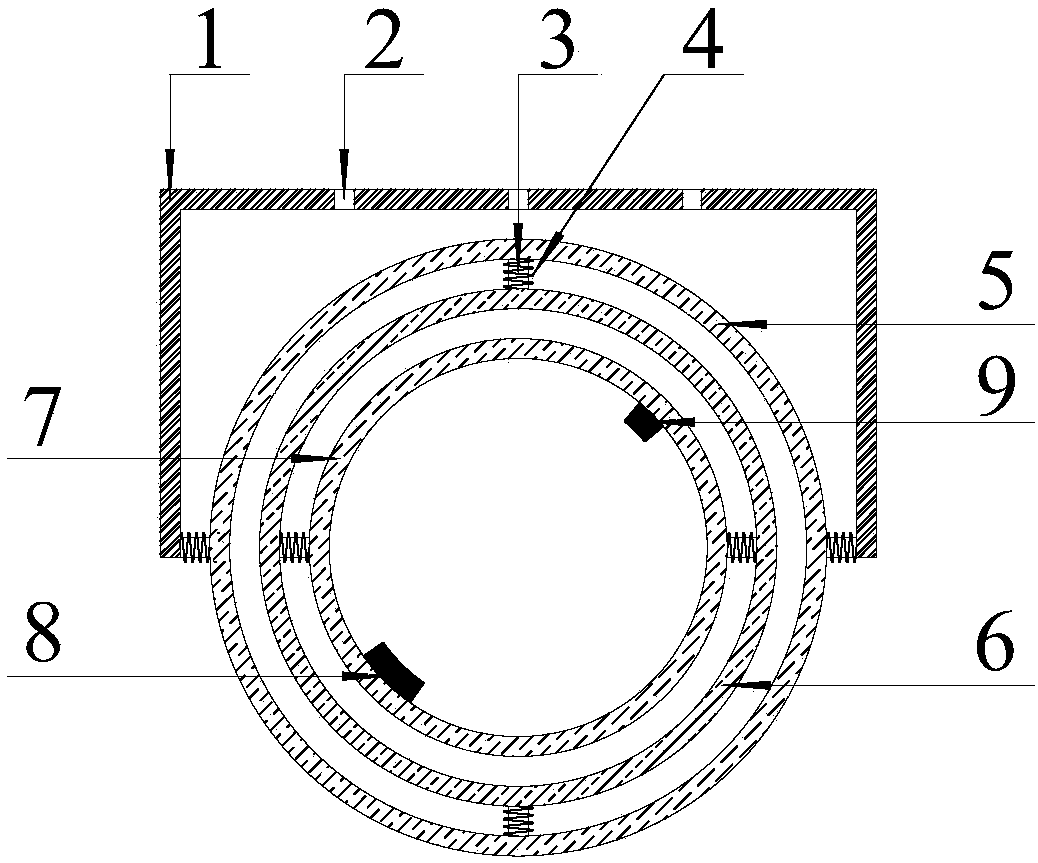

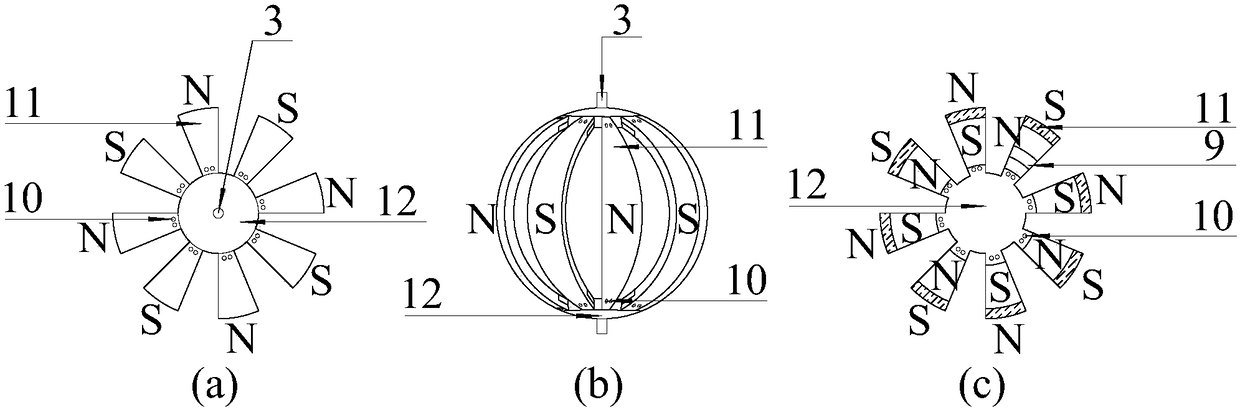

[0035] The damping device includes a box body, a connecting screw hole A, a rotating shaft, a torsion spring, an outer sphere, a middle sphere, an inner sphere, an additional mass A, an additional mass B, a connecting screw B, an inner sphere fan blade, The inner sphere base, the middle sphere fan blade, the middle sphere base, the outer sphere fan blade, and the outer sphere base; the outer sphere fan blade and the inner sphere fan blade are made of materials with excellent magnetic properties (such as: NdFeB ), and the middle spherical fan blade is made of a material with good electrical conductivity (such as copper). The rotating shaft, the box body, the inner sphere base, the middle sphere base and the outer sphere base are all made of non-magnetic materials (such as: aluminum alloy material, carbon fiber material).

[0036] The inner spherical fan blade is installed on the inner spherical base, and connected by bolts through connecting screw holes.

[0037] The inner sph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com