Heat dissipation method of infrared blood vessel in-situ display instrument

A technology for display instruments and heat dissipation methods, applied in instruments, projection devices, optics, etc., can solve the problems of short standby time, high power consumption, and difficulty in maintaining the temperature gradient of RLED, GLED and BLED bases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

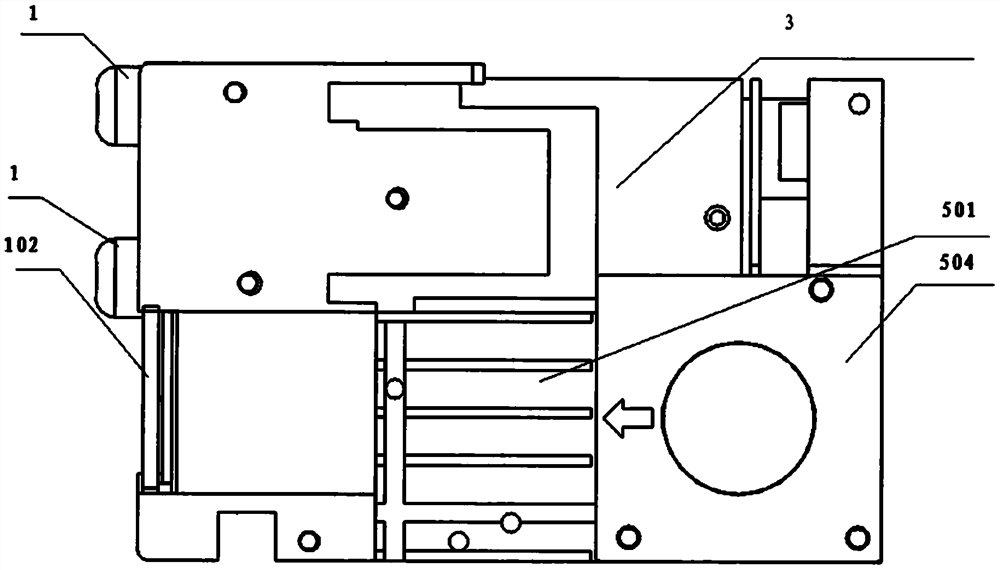

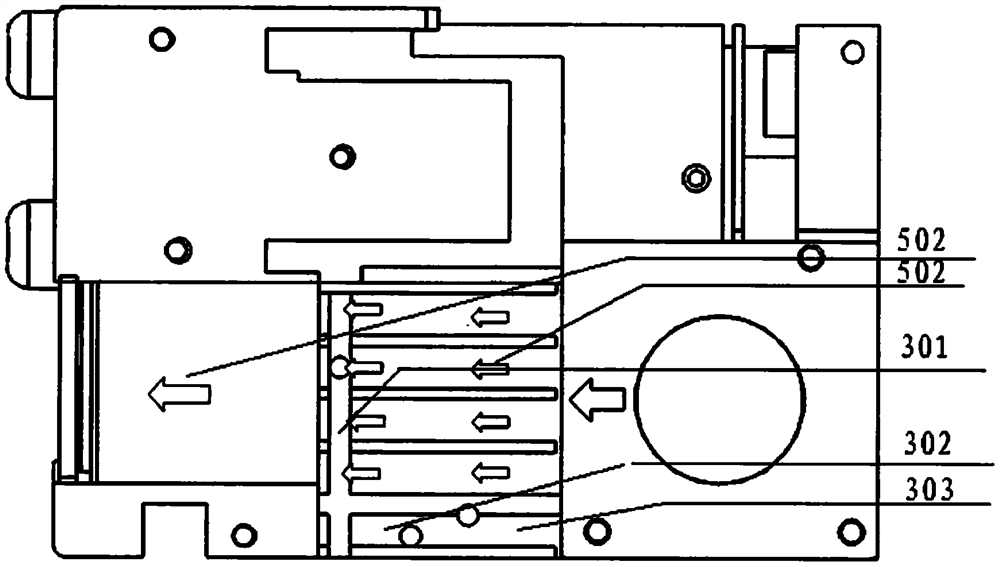

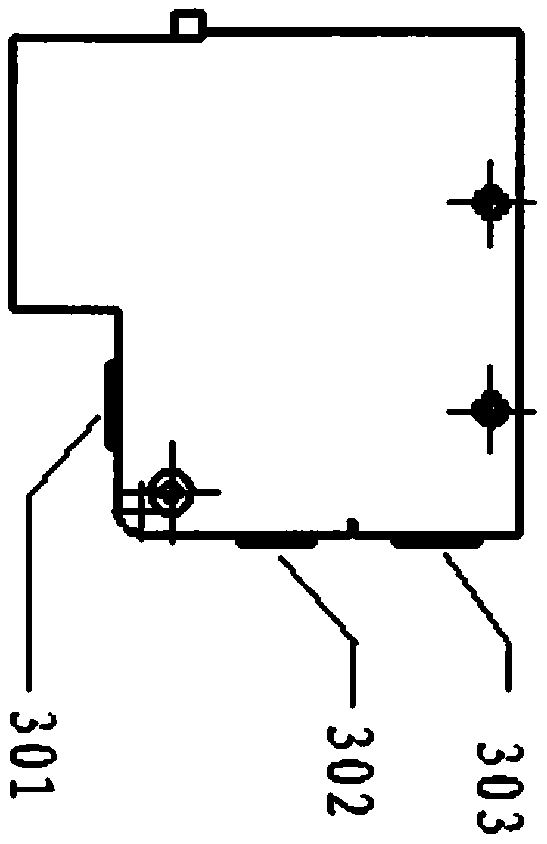

[0016] figure 1 It is a structural diagram of the whole machine of the heat dissipation method of an infrared blood vessel in-situ display instrument of the present invention, including an infrared light source module (1), an infrared camera (2), a projection module (3), a main control board (4), and a heat dissipation module ( 5); the heat dissipation module (5) adopts a fan (504) to extract cold air (502) from the outside of the instrument, and the cold air (502) is vertically inhaled from the back of the instrument, and blows on the infrared light source module (1 )superior.

[0017] The heat dissipation module (5) has multiple heat dissipation grooves (501), and the cold air takes away the heat of the projection module through the heat dissipation grooves, blows on the aluminum base (102) of the infrared light source (1), and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com