A wide-purpose quick-loading dust filter bag

A quick-loading, filter bag technology, used in transportation and packaging, dispersed particle filtration, separation methods, etc., can solve problems such as low installation efficiency, winding, and poor use of dust filter bags, achieving good results and avoiding winding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

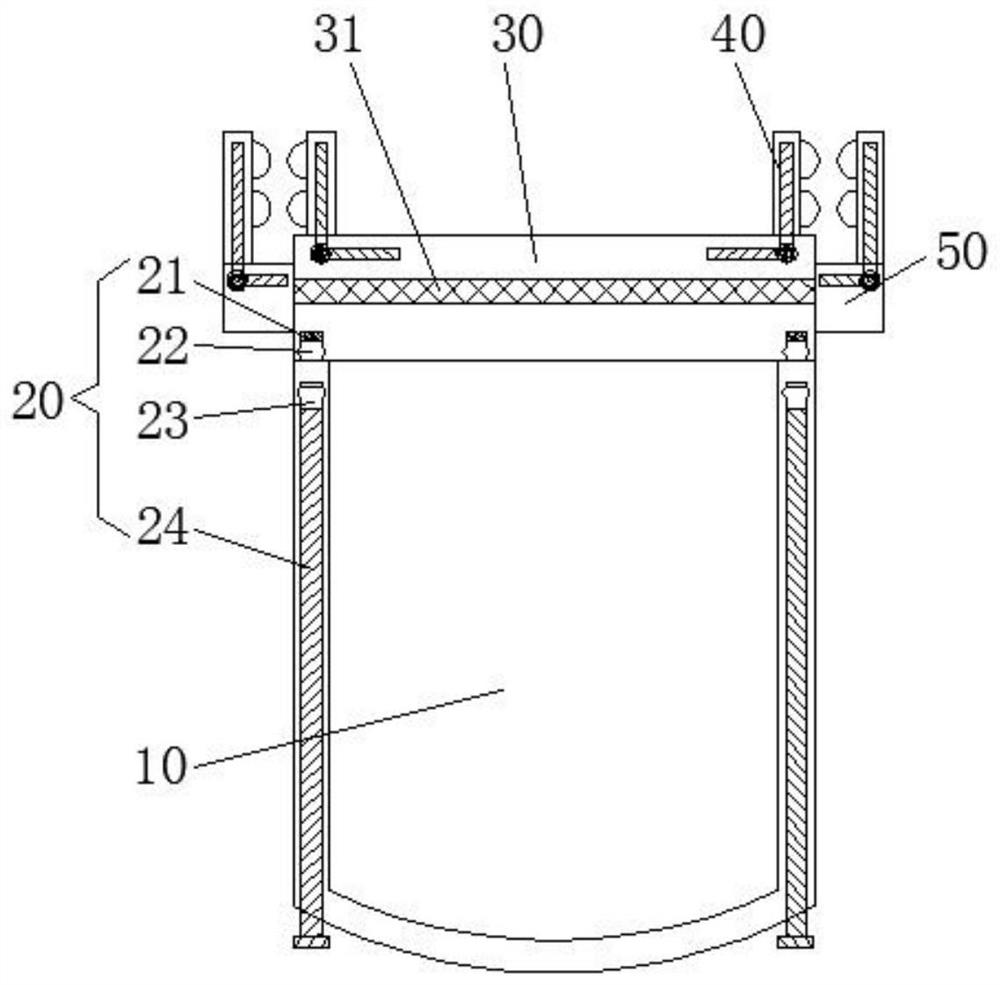

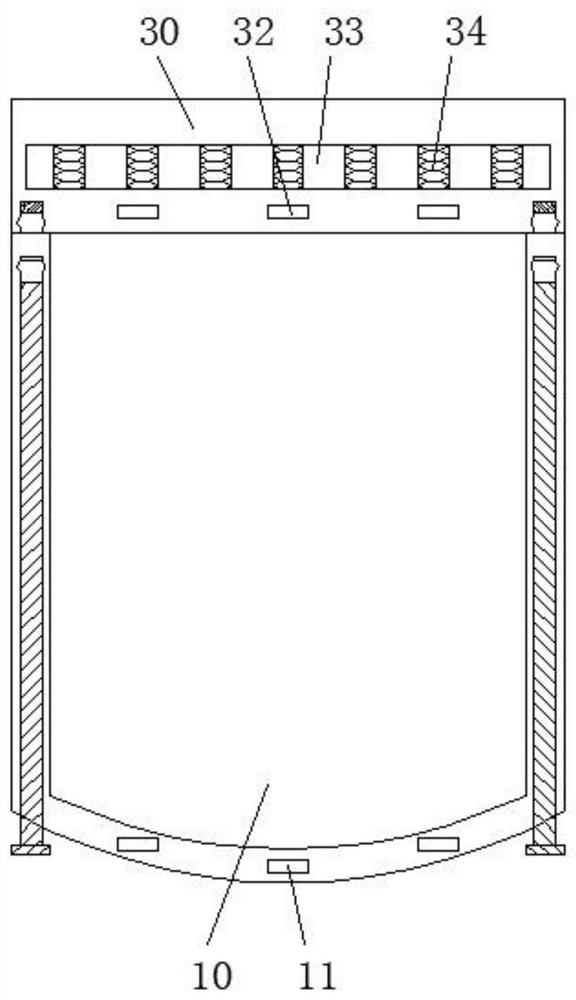

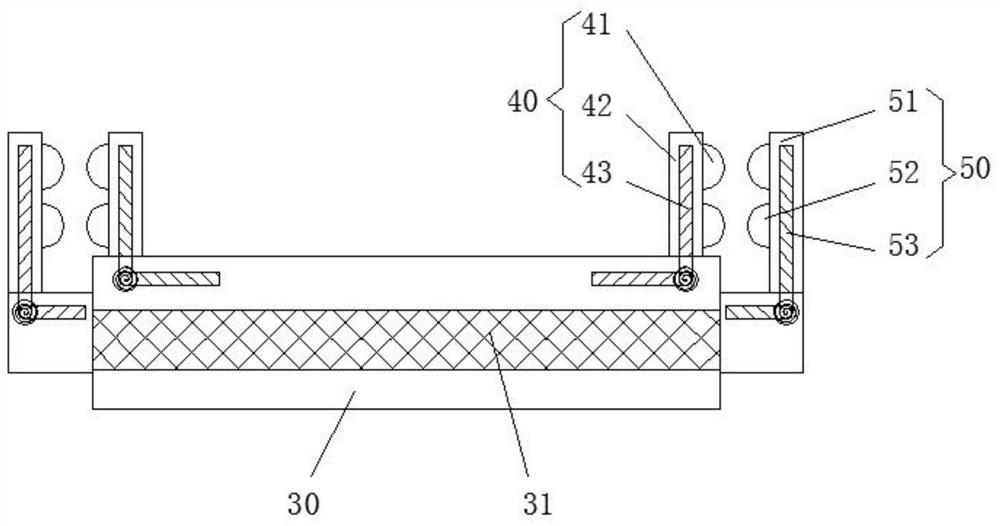

[0024] Such as Figure 1-4 As shown, a wide-purpose quick-loading dust filter bag includes a dust filter bag body 10, a positioning mechanism 20, a connecting ring 30, a first clip 40, and a second clip 50. The dust filter bag body The top of the top of 10 is provided with a connecting ring 30, and a positioning mechanism 20 is provided between the dust filter bag body 10 and the connecting ring 30, and the top of the connecting ring 30 is symmetrically provided with a first clamping piece near the edge. 40 and the second clip 50, the inside of the connection ring 30 is provided with a placement groove 33, and the placement groove 33 is provided with a buffer spring 34, and the side wall of the connection ring 30 is opposite to the placement groove 33 An elastic sealing strip 31 is provided at the position.

[0025] A connection ring 30 is provided on the dust filter bag body 10, and a first clamping member 40 and a second clamping member 50 are arranged symmetrically on the ...

Embodiment 2

[0034] Such as Figure 2-6As shown, a wide-purpose quick-loading dust filter bag includes a dust filter bag body 10, a positioning mechanism 20, a connecting ring 30, a first clip 40, and a second clip 50. The dust filter bag body 10 is provided with a connecting ring 30 on the top, and a positioning mechanism 20 is provided between the dust filter bag body 10 and the connecting ring 30. The top of the dust filter bag body 10 is symmetrically provided with a first clamping joint near the edge. 40 and the second clamping member 50, the inside of the connecting ring 30 is provided with a placement groove 33, and the buffer spring 34 is arranged in the placement groove 33, and the side wall of the connecting ring 30 is relatively opposite to the placement groove An elastic sealing band 31 is provided at the position 33 .

[0035] The first clamping member 40 includes a first protrusion 41, a fixed rod 42 and a first return spring 43, the fixed rod 42 is arranged near the edge of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com