Cold forming multi-station die for hollow rivet rivet

A cold forming, multi-station technology, applied in the direction of rivets, connecting components, etc., can solve the problems that the upsetting extrusion method cannot meet the requirements, and the double-click die or the one-die two-punch process cannot be used, so as to reduce the production cost and achieve high efficiency. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

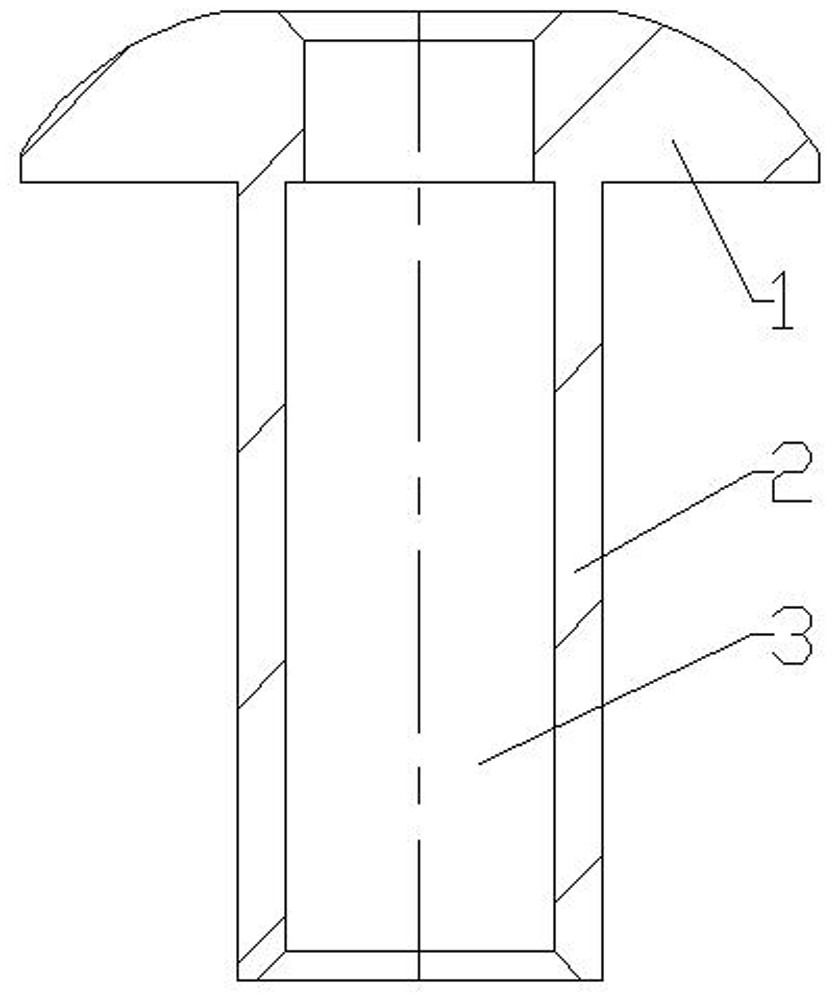

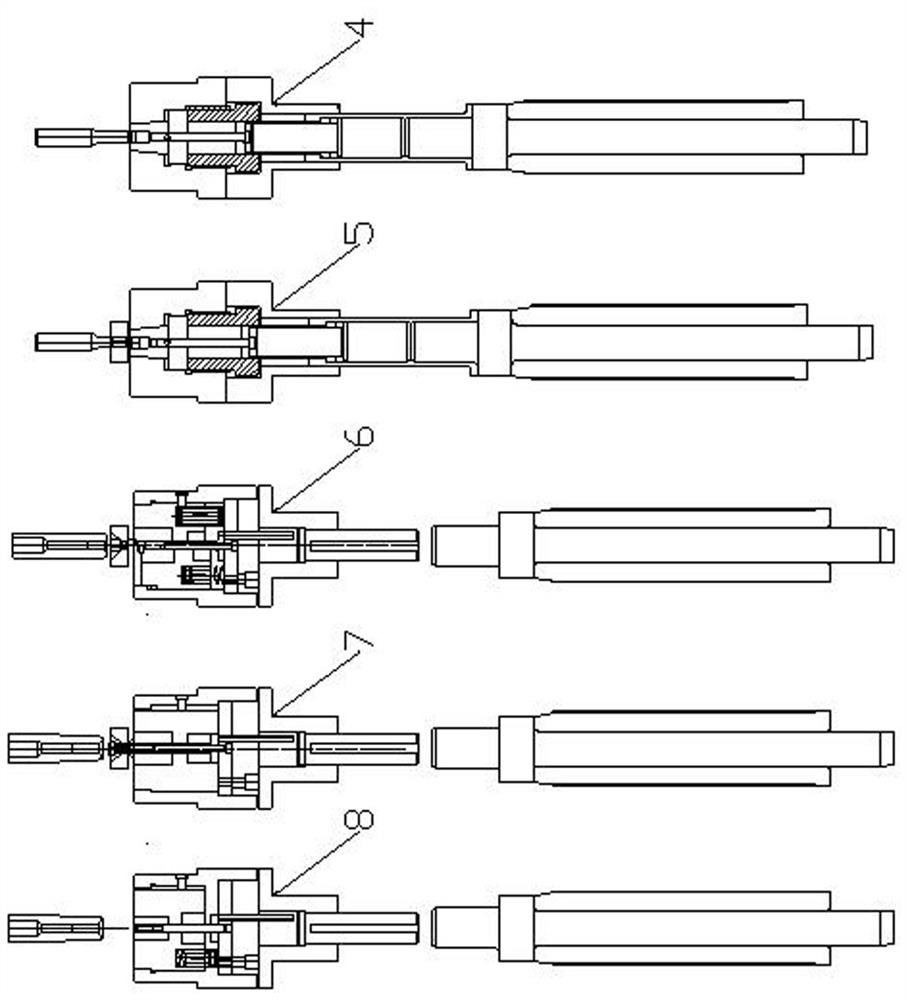

[0018] Such as figure 2 As shown, a multi-station die for cold forming of a hollow blind rivet includes a shaping die 4, a pre-forming die 5, a floating composite extrusion die 6, a floating finishing die 7 and punching dies arranged sequentially from right to left. Hole die 8, the shaping die is used for flattening the two ends of the disc material and the chamfering of the lower end (such as Image 6 shown), the preform die is used to extrude the nail shank (such as Figure 7 shown), the floating composite extrusion die is used to extrude the wrinkled nail head and the cavity in the nail shank (such as Figure 8 shown), the floating finishing die is used for finishing nail heads and shanks (such as Figure 9 shown), the punching die is used to punch out the cavity in the nail head (such as figure 1 shown);

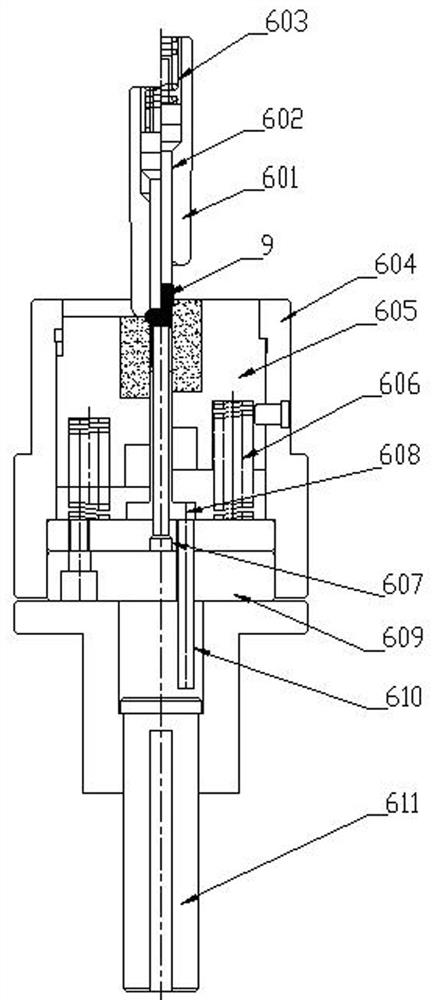

[0019] Such as image 3 with Figure 4 As shown, the floating composite extrusion die 6 is made up of an upper die and a lower die; as Figure 5 As shown, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com