A Worm Processing Mechanism with Reduced Weight

A processing mechanism and weight reduction technology, applied in the direction of worms, mechanical equipment, components with teeth, etc., can solve the problems of reducing costs and improving processing speed and precision, difficult to ensure the shape and position accuracy of tooth grooves, and low transmission efficiency of worms And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

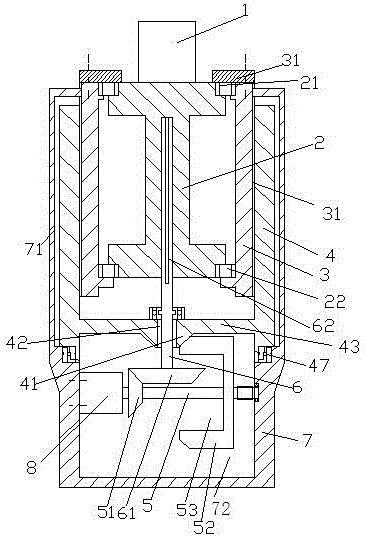

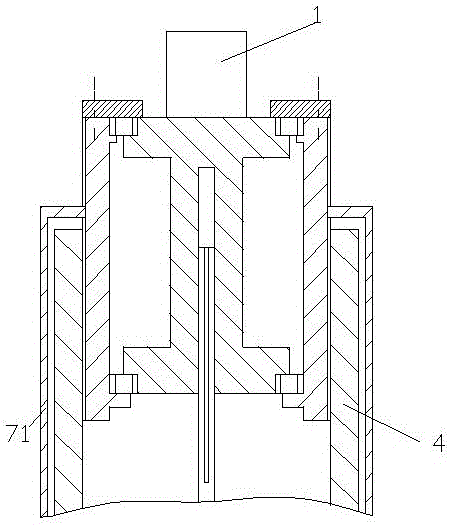

[0013] Attached below Figure 1-2 , the present invention will be described in detail.

[0014] A reduced weight worm machining mechanism for machining a blank 1 into a worm, said worm machining mechanism comprising a blank carrier 2, an externally threaded sleeve 3, an internally threaded drive sleeve 4 and a frame 7. The upper end of the blank carrier 2 is provided with an upper annular flange, and the lower end is provided with a lower annular flange, thereby forming an annular cavity between the upper annular flange and the lower annular flange, forming a The blank carrier 2 of the annular cavity reduces the weight of the worm machining mechanism; the upper end surface of the upper annular flange is used to carry the blank 1, and the upper annular protrusion of the blank carrier 2 The rim and the lower annular flange are axially fixedly installed in the sleeve 3 with external thread relative to the sleeve 3 with external thread through an upper bearing 21 and a lower bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com