External control mechanism for hollow built-in louver glass window

A control mechanism and glass window technology, which is applied to windows/doors, building components, building structures, etc., can solve the problems of vulnerable and sliding parts, unusable, defective strength and matching effects, etc., to avoid comprehensive absorption Combination, prevent deformation, improve the strength and reliability of cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

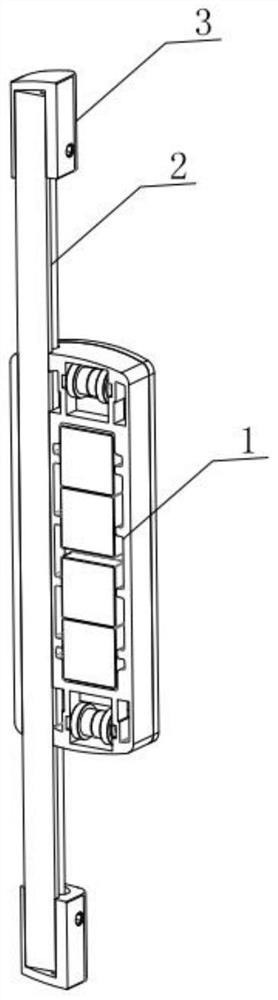

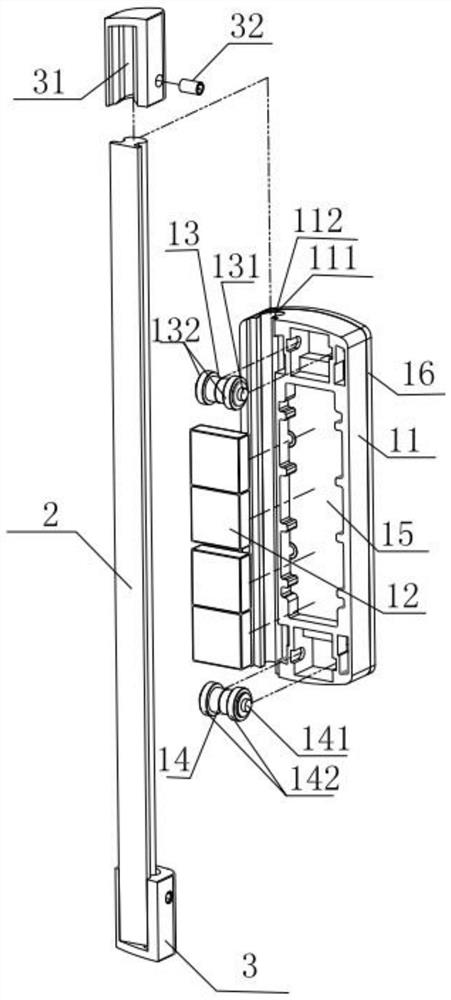

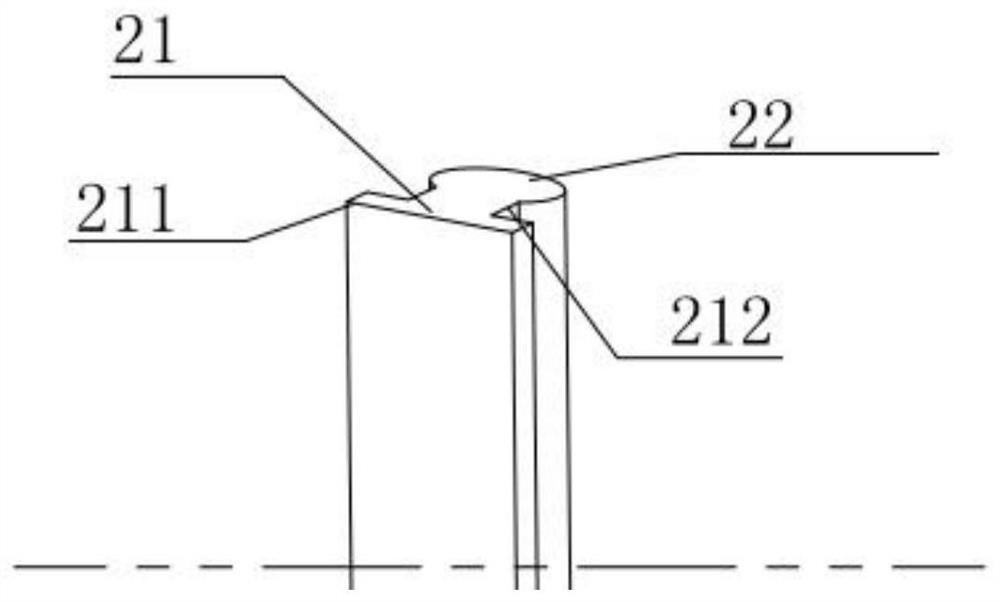

[0033] Such as figure 1 , figure 2 with image 3 An external control mechanism for a hollow built-in louver is shown, the hollow built-in louver includes a front glass 4 and a rear glass 5, and the external control mechanism includes an outer manipulator 1 and an outer manipulator slide rail 2; The outer manipulator 1 includes an outer manipulator housing 11, an outer manipulator magnetic block group 12, an upper scroll wheel 13, a lower scroll wheel 14 and a magnetic block suction positioning iron block 15; the outer manipulator housing 11 Facing the front glass side, along the transverse direction, there are the outer manipulator slide rail installation grooves and component installation grooves in turn, the outer manipulator slide rail installation grooves shown include the matching groove 111 and the stepped grooves set on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com