Clamp type testing device

A testing device and clamping technology, which is applied in the direction of measuring device, measuring device casing, measuring electricity, etc., can solve the problems of easy wrinkling of batteries, battery damage, wrinkle interference, etc., and achieve the effect of reducing test interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The aforementioned and other technical content, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

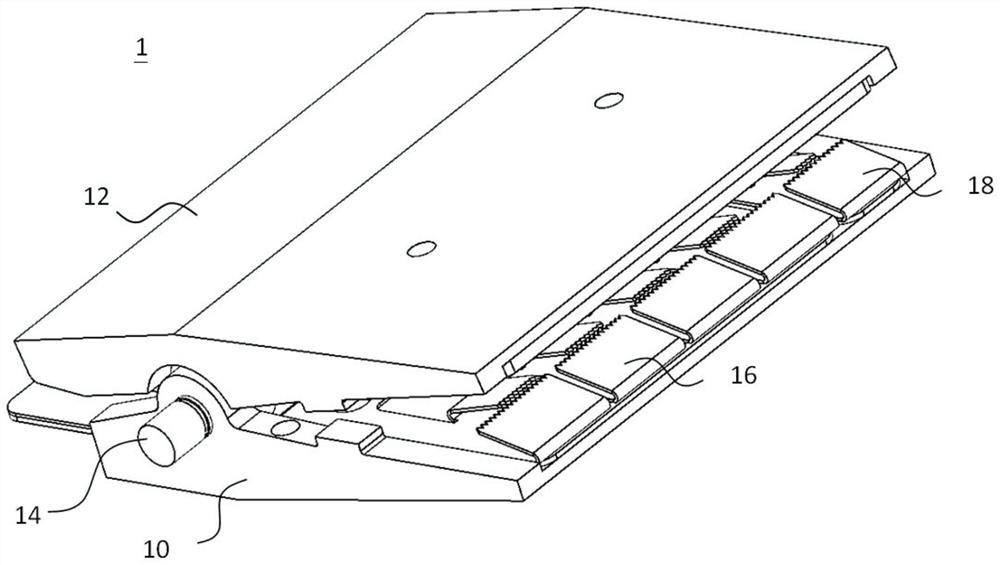

[0037] see figure 1 , figure 1 It is a three-dimensional schematic diagram illustrating a clip-type testing device according to an embodiment of the present invention. Such as figure 1 As shown, the clip-type testing device 1 includes a first clamping part 10 , a second clamping part 12 , a rotating shaft part 14 , a conductive part 16 and a measuring part 18 . The conductive member 16 is located between the first clamping component 10 and the second clamping component 12, and is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com