Thermal decomposition tank and method for decomposing, collecting and slowly releasing perfume components by using thermal decomposition tank

A spice ingredient and thermal decomposition technology, which is applied in the field of analysis devices, can solve the problems of limited application range and high price of pyrolyzers, and achieve the effects of less damage, less test interference, and greater convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0040] The technical solutions of the present invention are described below in combination with specific embodiments. The described embodiments are for better explaining the present invention, and should not be construed as limiting the claims of the present invention. Specific examples are as follows:

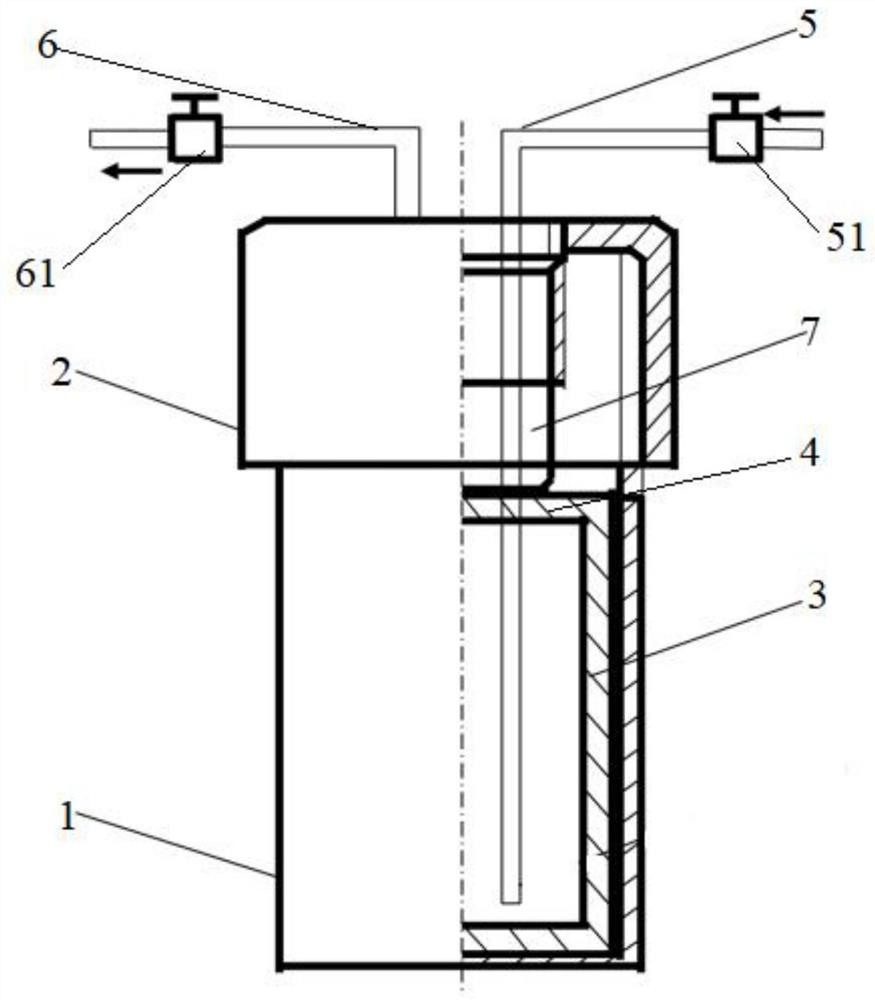

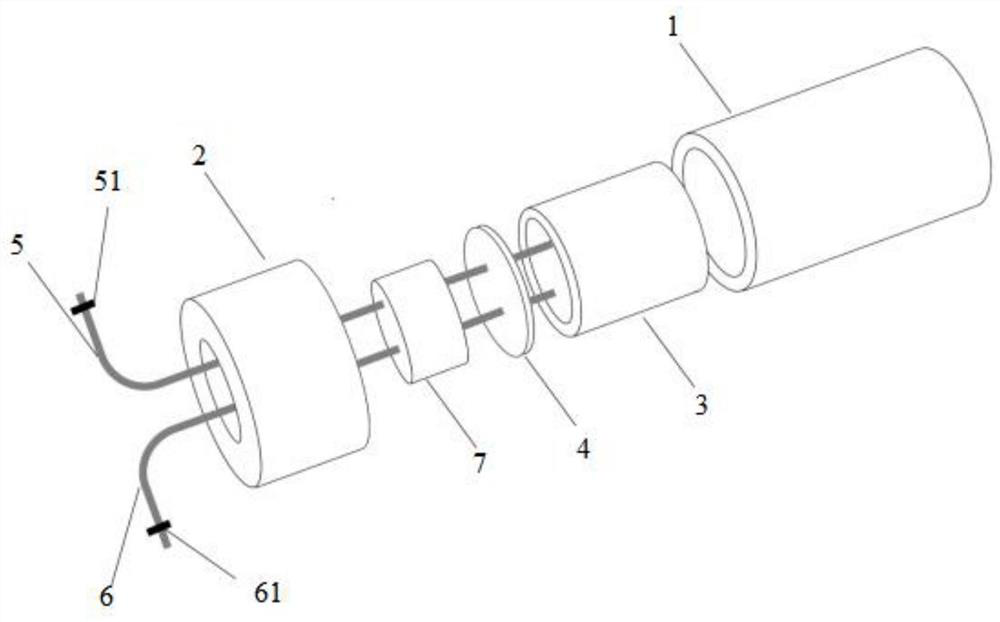

[0041] like figure 1 and figure 2 As shown, the thermal decomposition tank of the present invention includes the following components: an outer shell 1, which is cylindrical with a bottom seal and an upper opening; an outer shell cover 2, which is adapted to the upper opening of the outer shell 1; an inner shell 3, It is a cylindrical shape with a sealed bottom and an upper opening, and is arranged in the outer shell 1; an inner shell cover 4, which is adapted to the upper opening of the inner shell 3; an air intake pipe 5, which passes through the outer shell The cover 2 and the inner casing cover 4 extend into the bottom of the inner casing 3 and have an air inlet valve ...

Embodiment 1

[0048] Embodiment 1: use thermal decomposition tank of the present invention to be used for decomposing geraniol glycoside

[0049] Use the thermal decomposition tank of the present invention to decompose geraniol glycosides and collect the slow-release fragrance components. The steps are as follows:

[0050] Wrap 20 mg of geraniol glycosides in tinfoil, leave a vent hole on the tinfoil, place it in the inner casing 3, tighten the inner casing cover 4, and tighten the outer casing cover 2 and the outer casing 1; at 500 Test the sealing performance of the pyrolysis tank by passing nitrogen gas at ℃, and carry out the following steps under the condition of no air leakage;

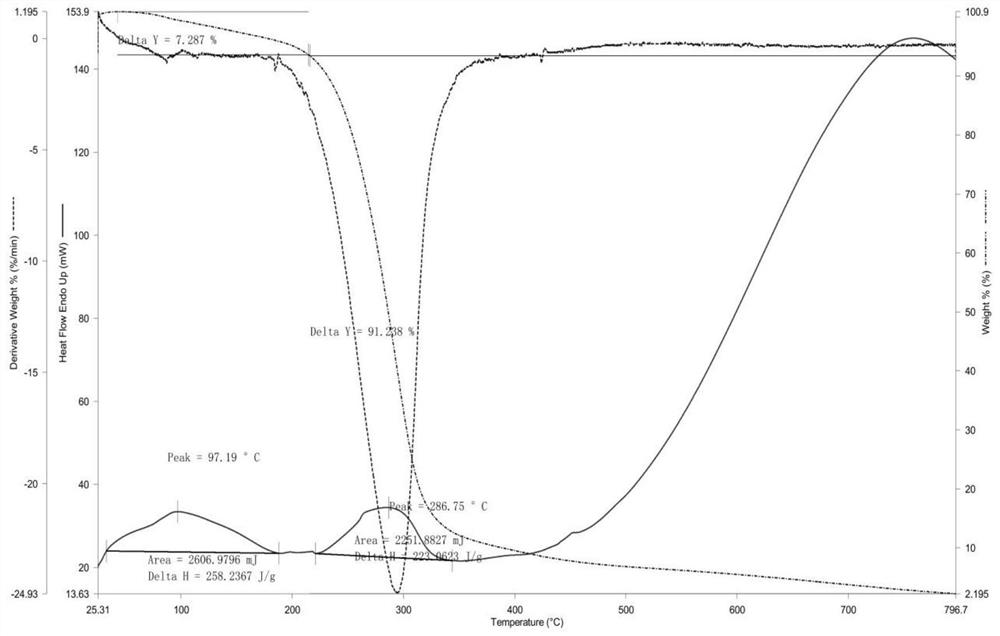

[0051] Put the pyrolysis tank in a high-temperature furnace, open the inlet valve 51 and the outlet valve 61, pass nitrogen gas at room temperature for 5 minutes, and close the inlet valve 51 and the outlet valve 61 after the air in the thermal decomposition tank is replaced; respectively raise the temperature ...

Embodiment 2

[0056] Embodiment 2: Use thermal decomposition tank of the present invention to also be used for decomposing eugenol / beta-cyclodextrin clathrate

[0057] Using the thermal decomposition tank of the present invention can also be used to decompose the eugenol / beta-cyclodextrin inclusion compound, and collect the slow-release fragrance components, the steps are as follows:

[0058] Wrap 100mg of eugenol / β-cyclodextrin clathrate in tinfoil, leave a vent hole on the tinfoil, place it in the inner shell 3, tighten the inner shell cover 4, connect the outer shell cover 2 with the outer shell Tighten body 1; pass nitrogen gas at 550°C to test the sealing performance of the pyrolysis tank, and perform the following steps under the condition of no air leakage;

[0059] Put the pyrolysis tank in a high-temperature furnace, open the inlet valve 51 and the outlet valve 61, pass nitrogen gas at room temperature for 5 minutes, and close the inlet valve 51 and the outlet valve 61 after the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com