An automatic control device and method for the overflow edge of cold-rolled strip coil

An automatic control device and a technology for cold-rolled strip steel, applied in the field of cold-rolled production, can solve the problem of irregular overflow direction, etc., and achieve the effects of easy disassembly and maintenance, reduction of production cost, and high control precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

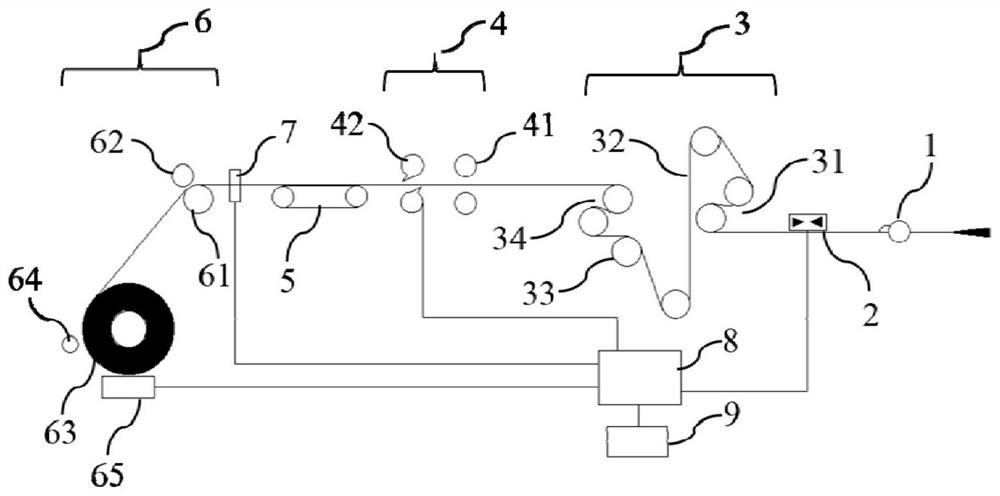

[0033] An automatic control device for the overflow edge of a cold rolled strip steel coil in this embodiment, such as figure 1 As shown, it includes a trimming shear 1, an automatic online width measuring instrument 2 is arranged downstream of the trimming shears 1, and the automatic online width measuring instrument 2 can automatically measure the strip steel conveyed by the trimming shears 1 upstream thereof. width, and feedback its value to the PLC controller 8; a tensioning mechanism 3 is provided downstream of the automatic online width measuring instrument 2, and the tensioning mechanism 3 includes a tensioning roller I31, which is wound with a tensioning roller I31. The strip steel is tensioned by the tensioning roller 131 and then passes through the vertically symmetrical vertical tensioning rollers 32 in turn. After the strip on the vertical tensioning roller 32 is manually measured, the value is input into the HMI. machine interface 9, the HMI man-machine interface ...

Embodiment 2

[0036] A method for automatic control of the curling overflow edge of a cold-rolled strip steel of the present embodiment, the basic structure is the same as that of the first embodiment, and the differences and improvements are as follows: figure 1 shown, including the following steps:

[0037] Step 1. Bandwidth measurement: The actual width of the strip steel measured by the automatic online width measuring instrument 2 is a unit millimeter; or the width of the strip steel on the vertical tension roller 32 is measured by manual width measurement, And input the measured value to the HMI man-machine interface 9, and the HMI man-machine interface 9 feeds back the signal to the PLC controller 8;

[0038] Step 2, coiling and shearing: the PLC controller 8 transmits the signal to the drum shear 42, and the drum shear 42 cuts the strip steel. At this time, the strip steel loses tension, and the strip steel is coiled by the coiler 63. , and the EPC automatic edge-aligning device 65...

Embodiment 3

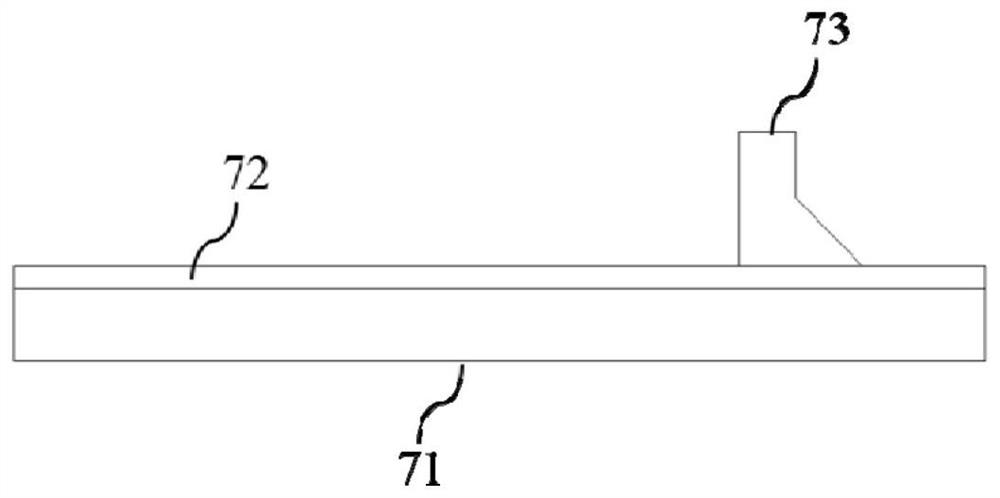

[0041] A method for automatic control of the curling overflow edge of a cold-rolled strip of the present embodiment, the basic structure is the same as that of the second embodiment, and the differences and improvements are as follows: figure 1 As shown, in step 3, when producing the type of strip steel with the risk of overflow edge, the automatic control mechanism 7 for overflow edge is activated, and when the strip steel in the coiling area is 10 meters away from the position of the drum shear 42, the linearity calculated by the PLC controller 8 is calculated. The displacement of the motor 71, in which the displacement of the operation side is E1 unit millimeter, E1=C1-200; the displacement of the transmission side is E2 unit millimeter, E2=C2-200; The displacement of the operation side is E1 unit millimeter, E1=C1- f1, f1 are the correction values of the overflow edge on the operation side, which can be modified on the HMI man-machine interface 9; the displacement of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap